Pipe pile hole maker with concrete bottom sealing, pipe cover and wings and construction process thereof

A technology of concrete and hole former, applied in the field of foundation engineering, can solve problems such as applicability restriction, and achieve the effects of reducing post-construction settlement, good quality and increasing strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

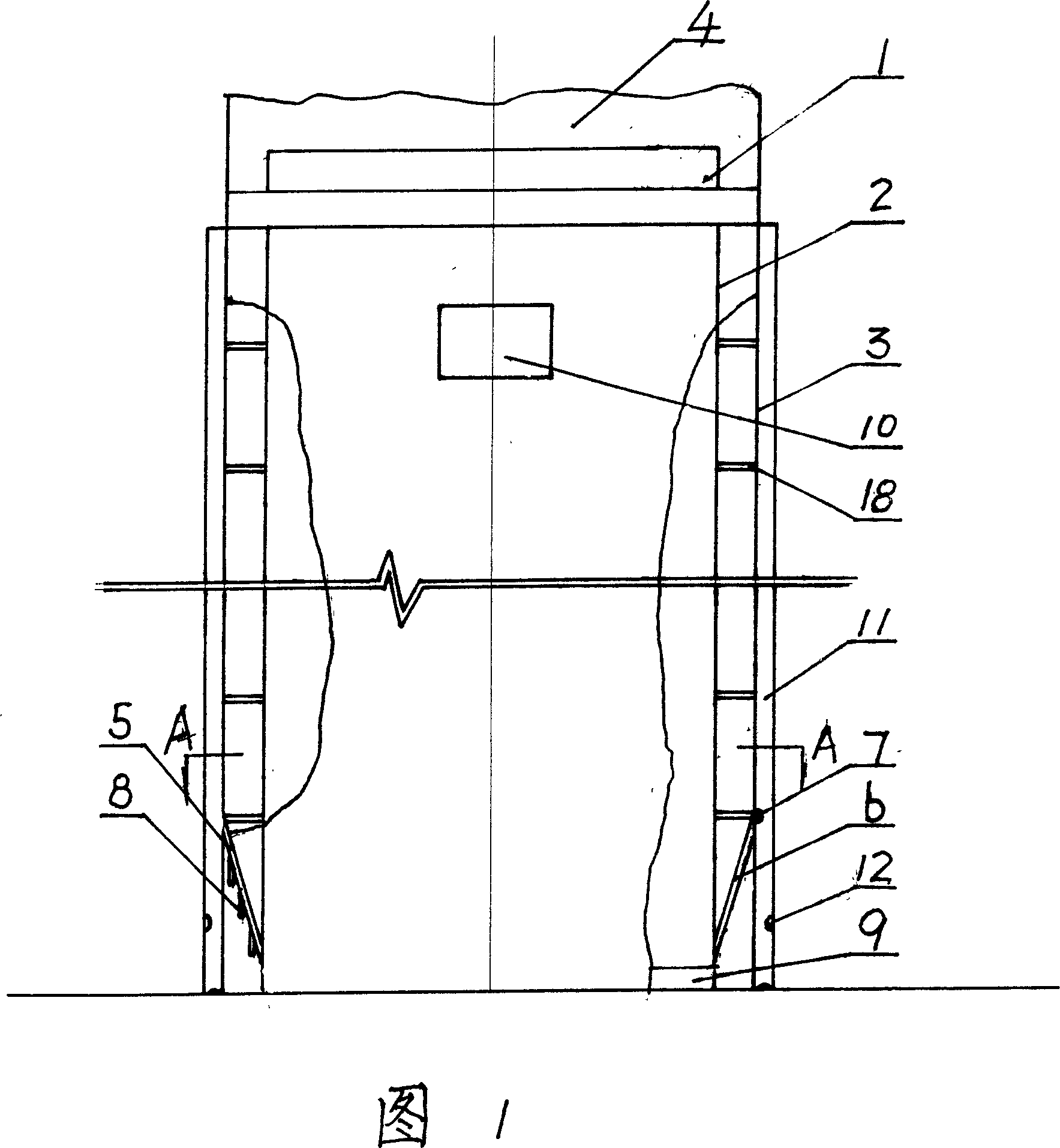

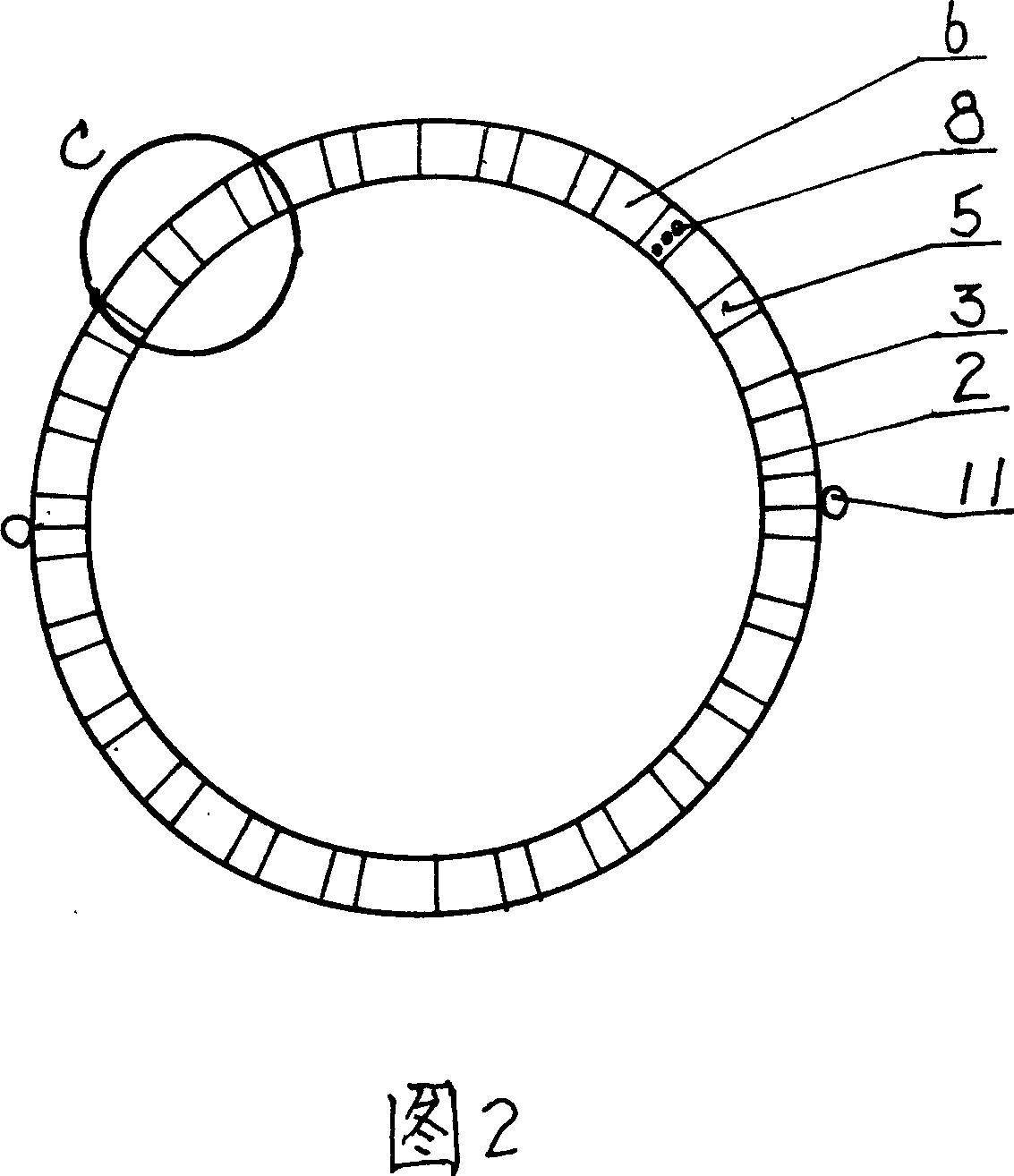

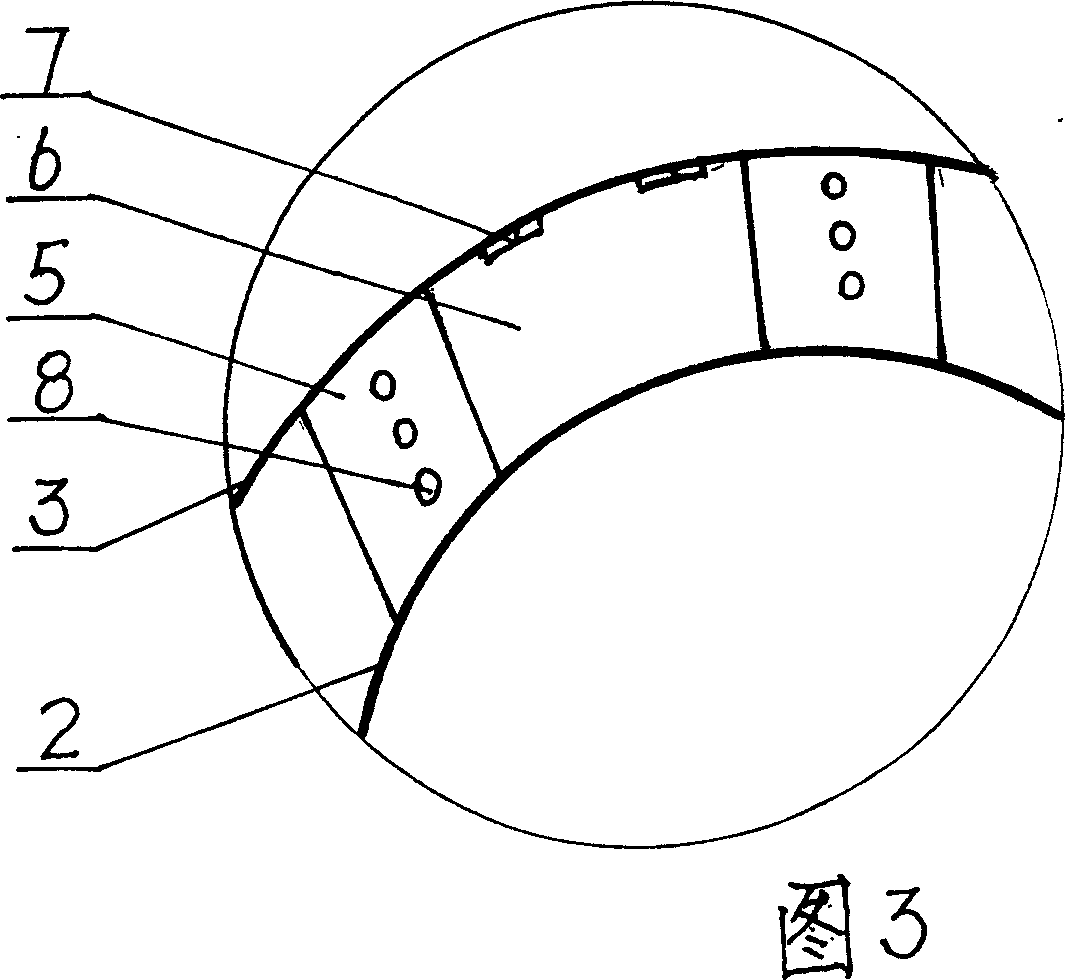

[0038] Concrete barrel (pipe) piles for house construction plus reinforcement cages, as shown in Figures 1-3: the concrete bottom cover, the barrel (pipe) pile with pile caps and pile wings are connected to the vibrating joint 1, and the vibrating joint 1 is connected with the high-frequency hydraulic vibrating hammer 4 through a hydraulic clamp, and then it is integrated with the cavity structure of the inner casing 2 and the outer casing 3 in the middle. Support bar 18, when inner casing 2 and outer casing 3 move downward, can not change its relative position, to ensure the size of the cavity structure, the spud can structure is connected under the hole forming device, and it is formed by the circumference of the cavity structure cross section It consists of a plurality of divided petals that are evenly divided. The divided petals connect the inner sleeve 2 and the outer sleeve 3. At the bottom, the inner sleeve 2 is long and the outer sleeve 3 is short. Therefore, the inner ...

Embodiment 2

[0042] Concrete barrel (pipe) piles for road construction do not add reinforcement cages, as shown in Figures 1-3: the concrete back cover, the barrel (pipe) pile hole former with pile caps and pile wings are exactly the same as in Embodiment 1. The construction process is shown in Fig. 5, Fig. 6 and Fig. 8: place the special concrete-backed winged cylinder (pipe) pile hole former at the foundation to be driven, and use a special laser inclinometer to measure the vertical direction of the hole former. degree; start the high-frequency hydraulic vibratory hammer (or electric vibratory hammer), and drive the tube (tube) pile hole forming device connected to it to vibrate downward; when the bottom of the tube (tube) pile hole forming device sinks into the predetermined design depth , through the high-pressure concrete pump and the nozzle under the high-pressure grouting pipe, concrete mortar is sprayed into the cavity of the bearing layer of the cylindrical pile and the annular cav...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com