Package structure and method for thermo-optical switch array/modulator

A thermo-optic modulator and thermo-optic switch technology, which is applied in the field of device packaging, can solve the problems of expensive needs, expensive integrated circuit chips, and poor heat dissipation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

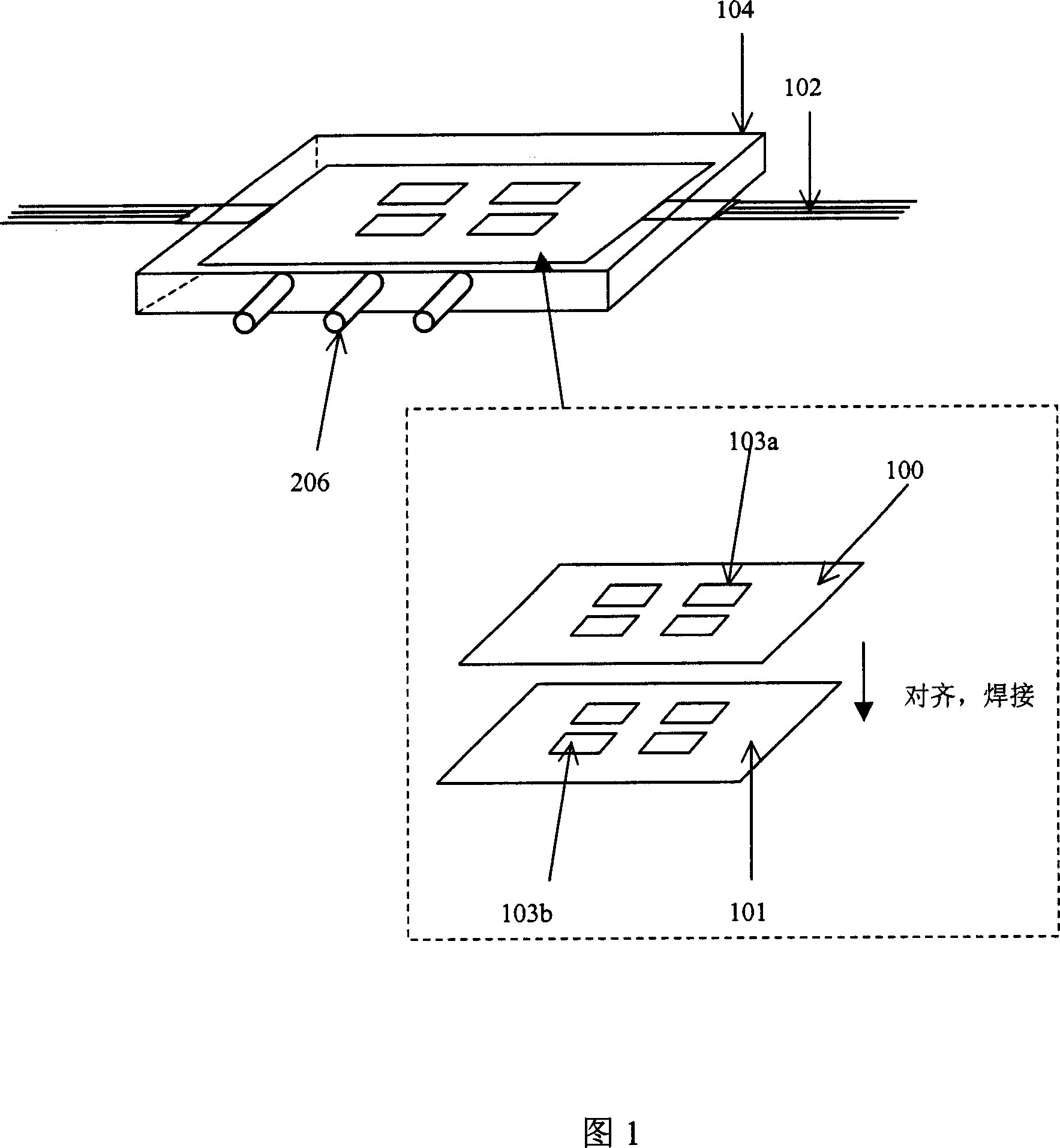

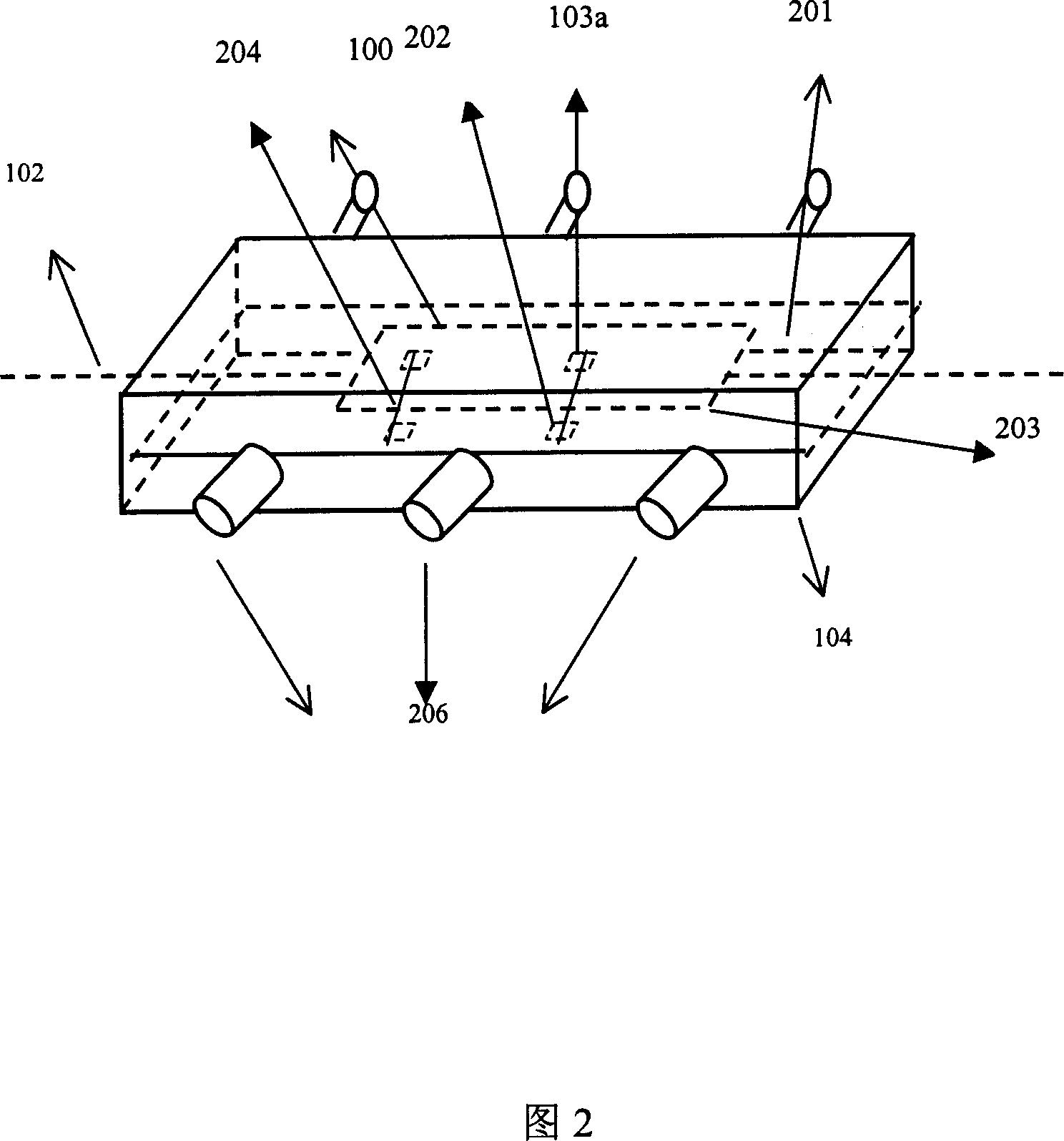

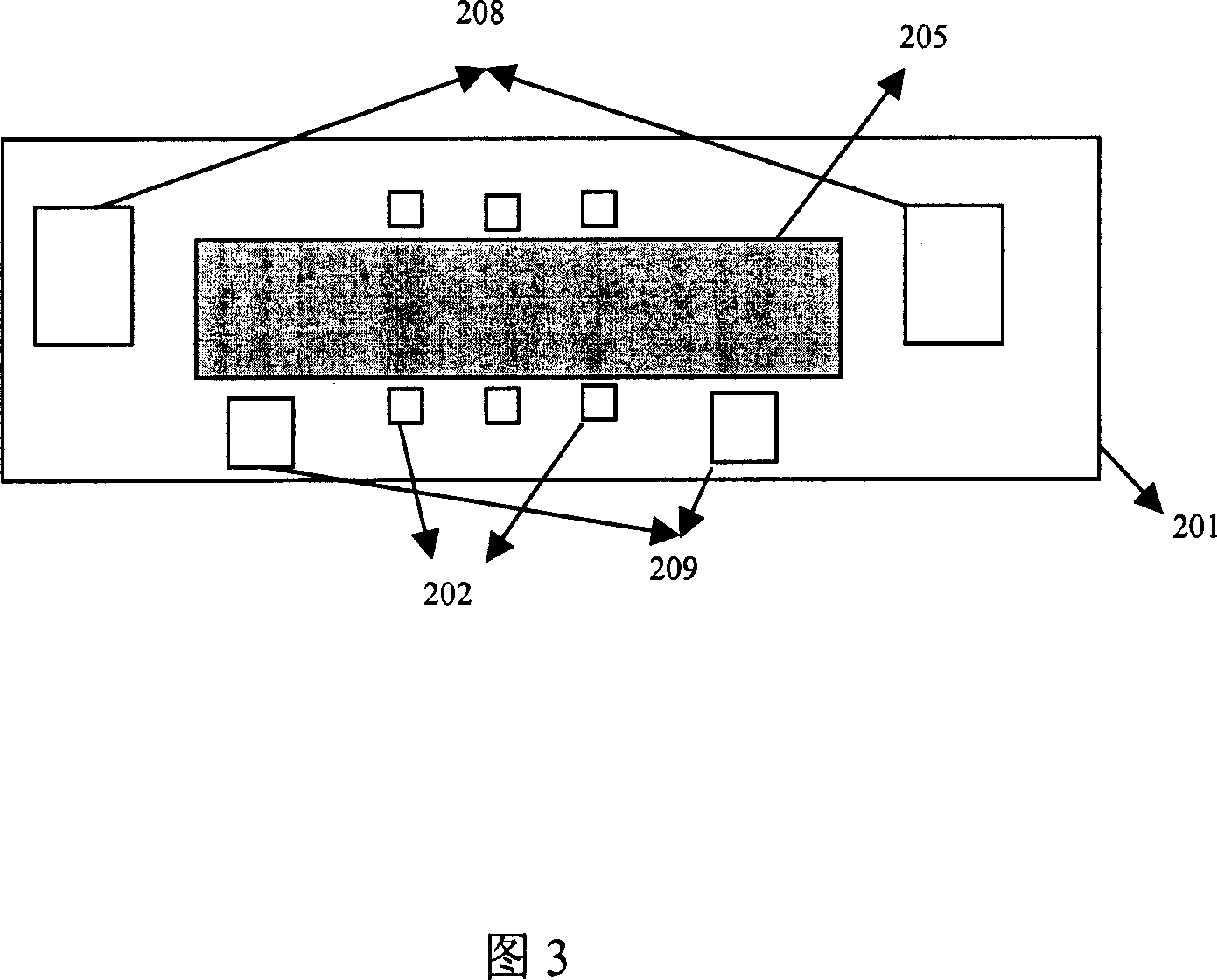

[0049] Please refer to FIG. 2 to FIG. 4 , which show the structure of the selected embodiment of the present invention.

[0050] The present invention relates to a packaging structure of thermo-optic switch array / modulator and its packaging method. The main part of the structure is a printed circuit board with a metal heat dissipation area and a control circuit pattern.

[0051] Figure 2 shows an overall schematic of the package structure. After the thermo-optic switch array / modulator chip 100 is coupled with the optical fiber array 102, it is pasted on the heat dissipation metal area 205 of the printed circuit board 201 by using a colloid with good thermal conductivity and electrical insulation. The drive circuit has been formed on the printed circuit board 201 The pattern, the electrode 103a of the thermo-optic switch array / modulator chip 100 and the output electrode 202 of the printed circuit board are electrically connected by pressure welding, and the control circuit is c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com