Membrane cleaning device and method in membrane separating technology and its application

A membrane cleaning and membrane separation technology, applied in the field of membrane separation, can solve the problems of unfavorable use of membranes, limited backwash frequency, poor backwash cleaning effect, etc., to optimize the backwash effect, strengthen the aeration effect, and the backwash effect. good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

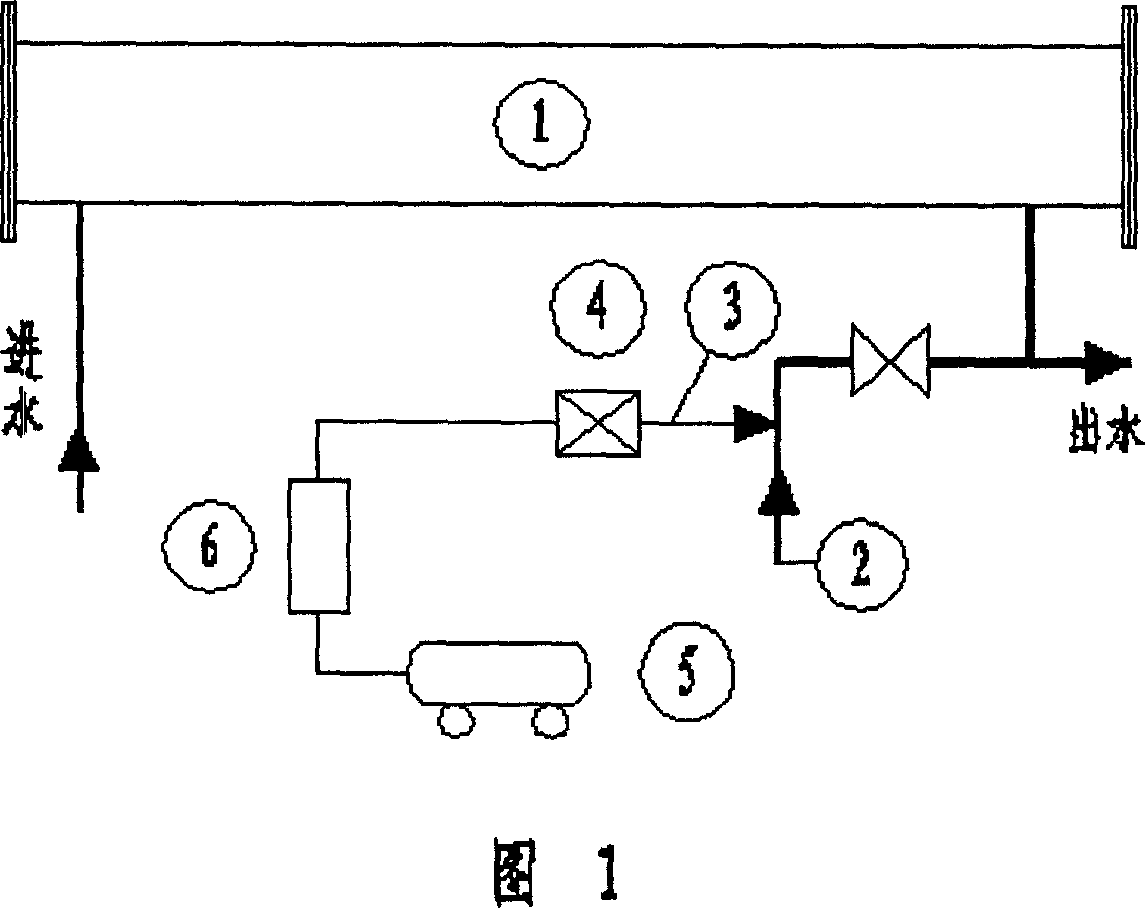

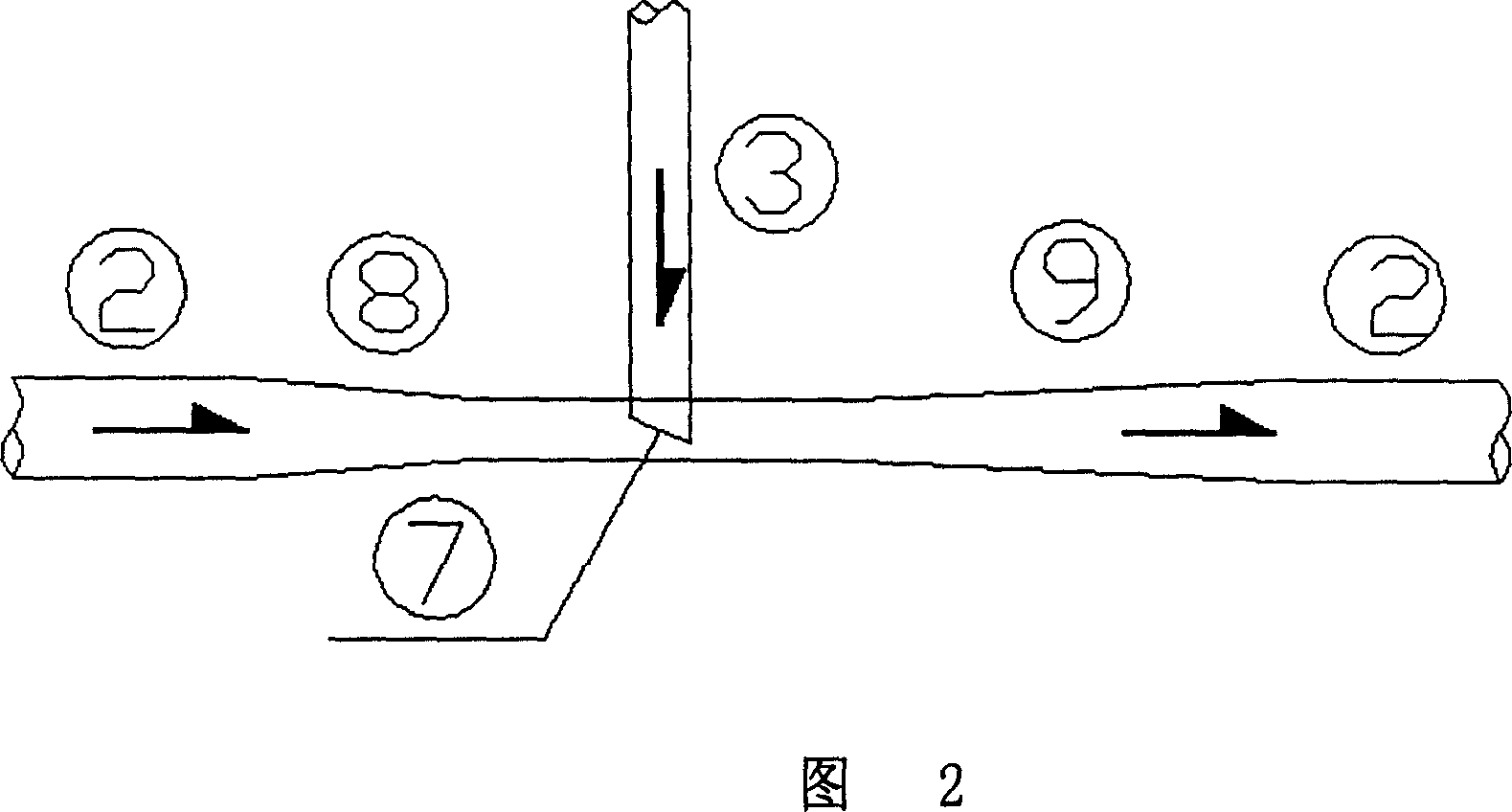

[0045] Figure 1 is a schematic diagram of the membrane cleaning device of the present invention, 1: membrane filter 2: backwash water inlet pipeline 3: pulse air pipeline 4: pulse valve 5: air compressor 6: air purifier.

[0046] A membrane cleaning device in membrane separation technology is realized in this way, including a membrane filter 1, a backwash water inlet pipeline 2 and a pulse air pipeline 3; the membrane filter 1 is connected to the backwash water inlet pipeline 2, and the pulse The air pipeline 3 is connected with the backwash water inlet pipeline 2, and periodically adds compressed air to the water flow in the backwash water inlet pipeline.

[0047] The membrane cleaning device also includes a pulse valve 4 and an air compressor 5 that can generate a pulsed oscillating air flow; the pulse valve 4 is directly connected to the pulse air pipeline 3 and then stretched into the backwash water inlet pipeline 2 Middle; The air compressor 5 is connected with the pulse ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com