Turbo charged internal-combustion engine for exhaust system with an SCR catalytic equipment

A technology of SCR catalyst and exhaust gas turbine, which is applied to internal combustion piston engines, exhaust gas treatment, exhaust devices, etc., can solve the problems of expensive exhaust gas after-treatment systems, inability to hydrolyze urea, and lower temperature levels.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

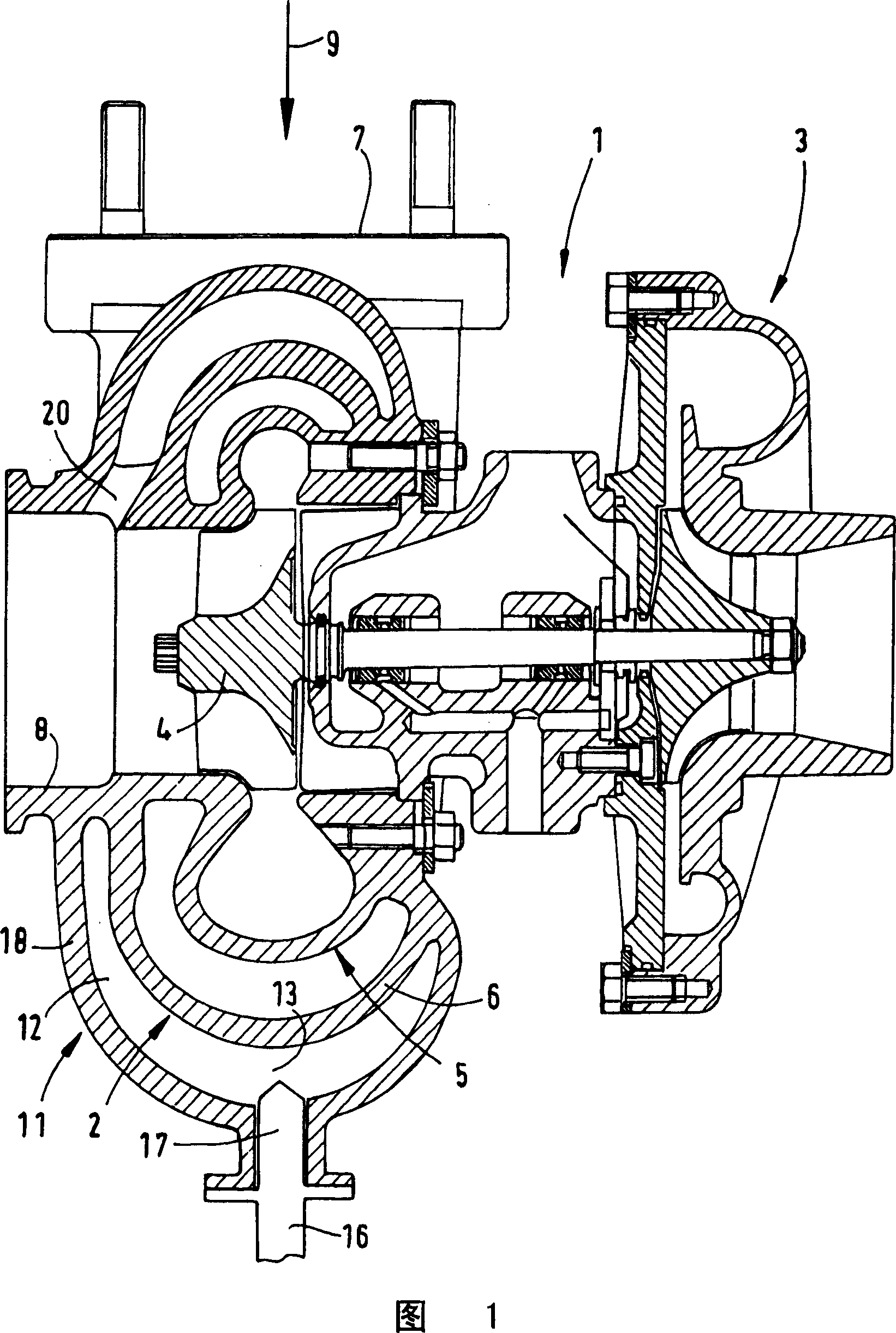

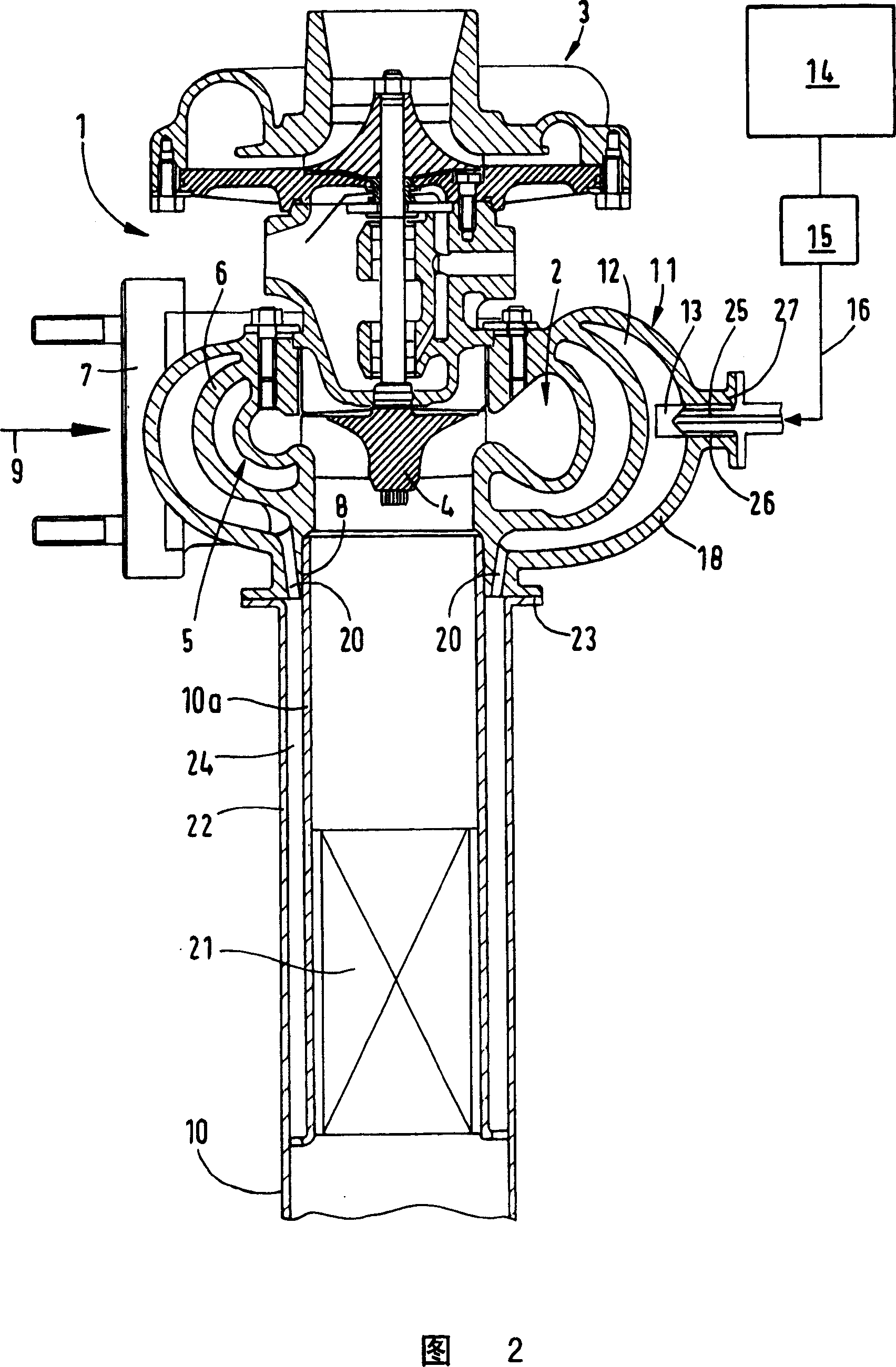

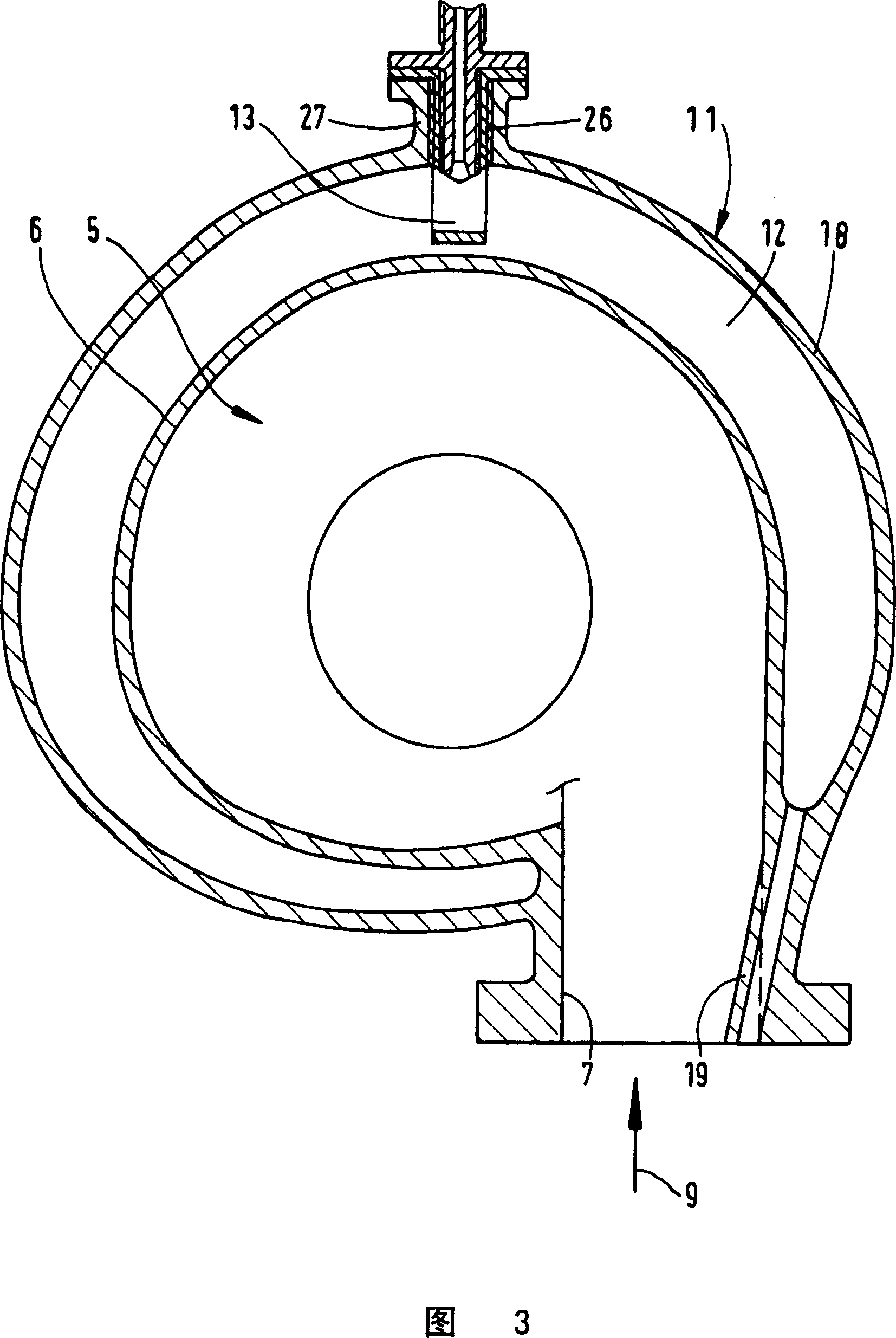

[0026] In the drawing, 1 denotes the exhaust gas turbocharger, 2 denotes the exhaust gas turbine of the exhaust gas turbocharger, and 3 denotes the compressor of the exhaust gas turbocharger. According to the invention, only the exhaust gas turbine 2 is of interest. Here, 4 designates the turbine wheel of the exhaust gas turbine, and 5 designates the turbine body of the exhaust gas turbine. 6 denotes the outer wall of the turbine body, 7 denotes the turbine inlet, and 8 denotes the turbine outlet.

[0027] The turbine inlet 7 of the exhaust gas turbine 2 is connected to an exhaust pipe section, such as an elbow or an exhaust manifold, through which the exhaust gas turbine receives energy from a likewise not shown internal combustion engine, in particular from a diesel engine of a motor vehicle. Exhaust gases from the engine delivered according to arrow 9. Connected to the outlet 8 of the exhaust gas turbine 2 is an exhaust line 10 in which, downstream of the exhaust gas turb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com