Thinfilm transistor device for reducing leaping voltage

A technology of thin film transistors and devices, which is applied in the field of liquid crystal displays, can solve problems such as crosstalk and picture quality degradation, and achieve the effects of reducing production capacity, increasing process cycle, and improving picture display quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

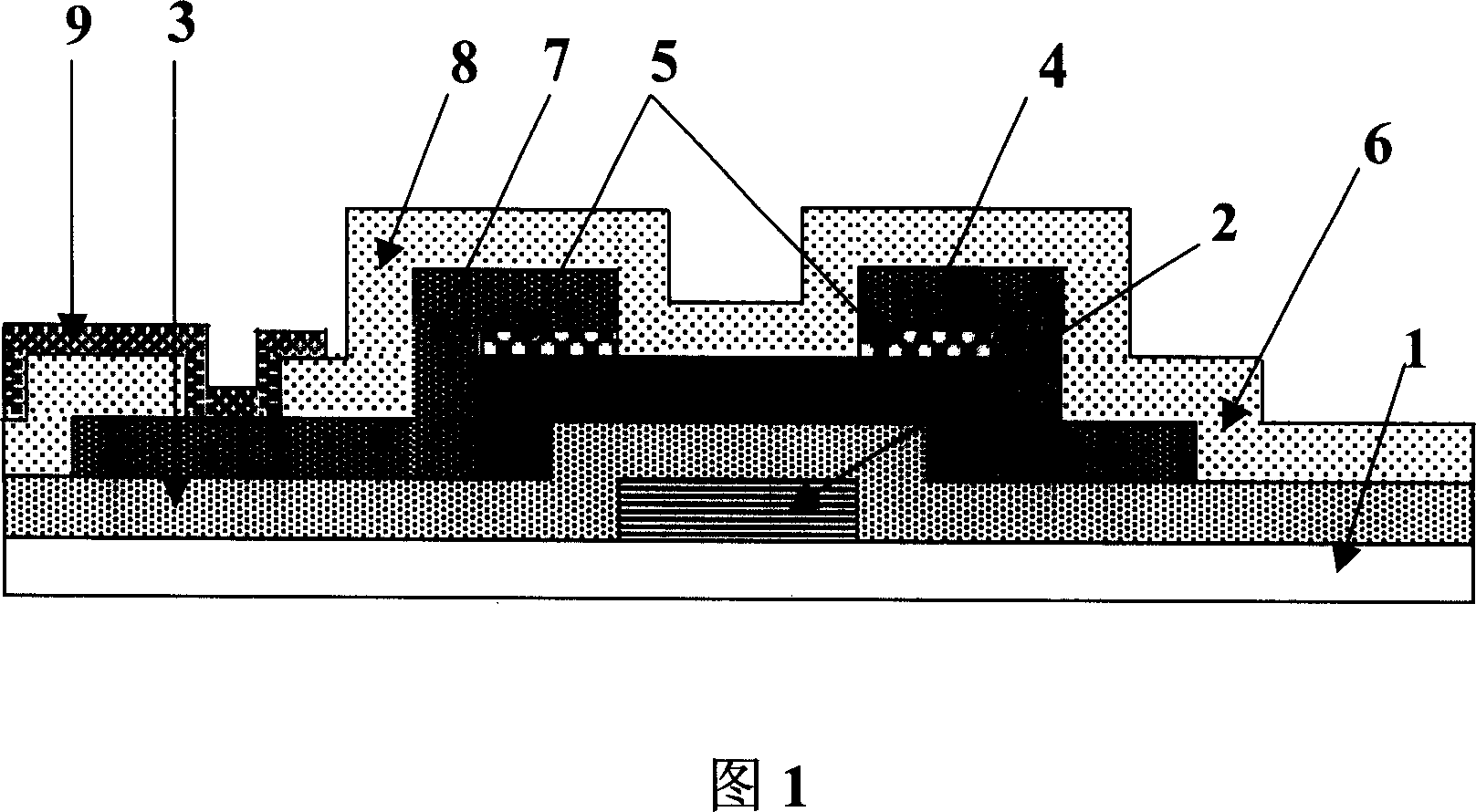

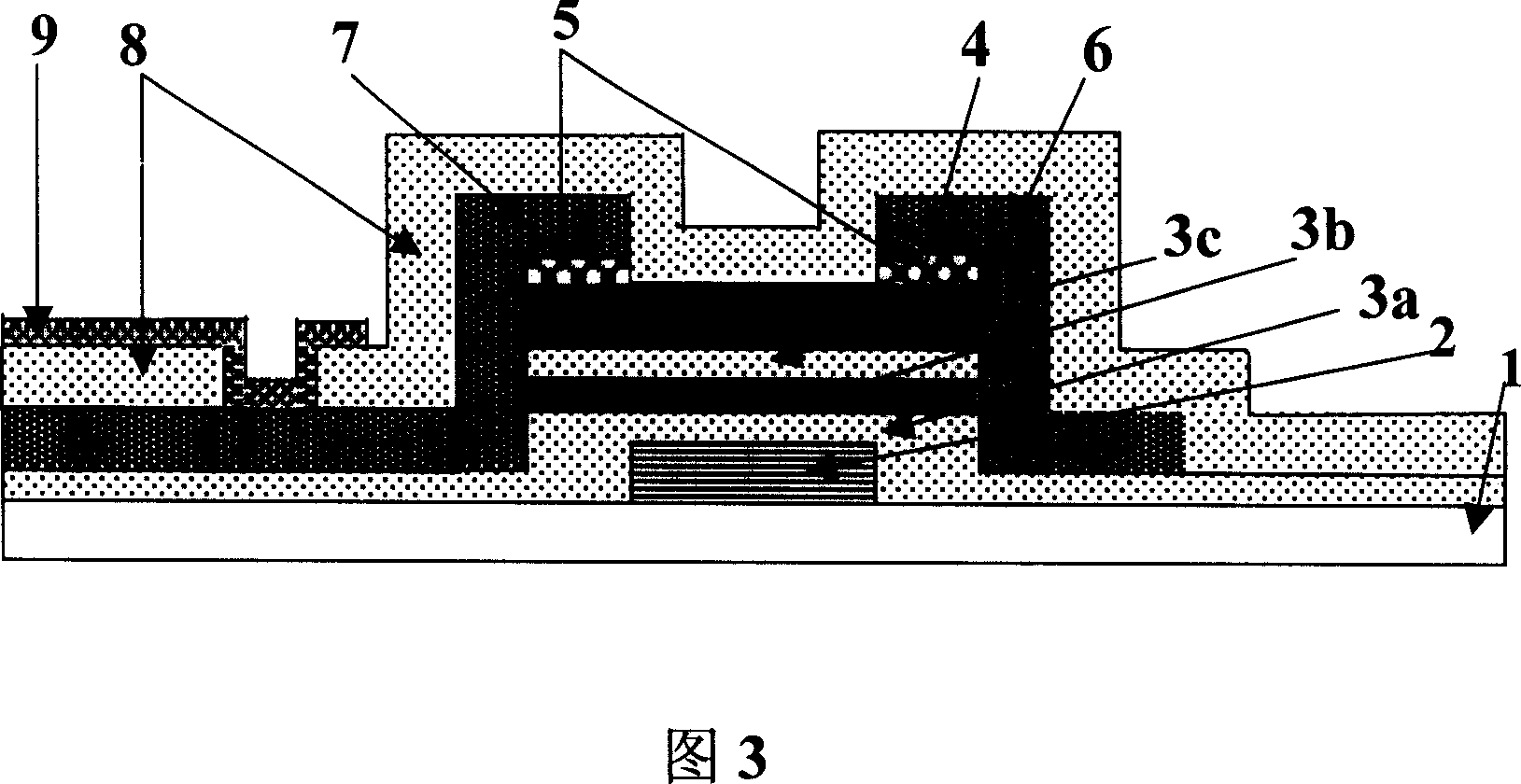

[0026] The present invention will be described in more detail below in conjunction with the accompanying drawings and embodiments.

[0027] As shown in Figure 3, the upper and lower films of the gate insulating layer structure under the active layer of the thin film transistor device are silicon nitride, and the intermediate film can be silicon oxide, silicon oxynitride (SiON), fluorine-doped silicon oxide (FSG), carbon-doped silicon oxide (carbon-doped SiO2), silicon nitride (SiC), other doped silicon nitride with low dielectric constant, organic insulating medium with low dielectric constant, etc. Because oxygen-rich silicon oxide (O-rich SiOx) and nitrogen-rich silicon nitride (N-rich SiNx), their dielectric constants have the same variation trend.

[0028] The thickness of the upper layer silicon nitride (etching stop layer) film 3c of the gate insulating layer under the active layer of the thin film transistor is 10 nanometers to 200 nanometers, and the thickness of the l...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com