Red long-persistence nano-luminescent materials, its production and use

A nano-luminescent material, long afterglow technology, applied in luminescent materials, chemical instruments and methods, instruments, etc., can solve problems such as short afterglow, and achieve the effects of not easy precipitation, excellent luminescence performance, and good chemical stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] Preparation of ultra-long afterglow luminescent material (sample 1)

[0039] in Eu 2 o 3 and Dy 2 o 3(99.99% pure), Cr(NO 3 ) 3 9H 2 O, Sr(NO 3 ) 2 , Al(NO 3 ) 3 9H 2 O and H 3 BO 3 , EDTA (both analytically pure) is raw material, takes by weighing 0.3080g Cr (NO 3 ) 3 9H 2 O, 5.2908gSr(NO 3 ) 2 and 34.6995g Al(NO 3 ) 3 9H 2 O was dissolved in deionized water and weighed 0.1355g Eu 2 o 3 and 0.2872g Dy 2 o 3 Concentrated HNO 3 Heat to dissolve, mix the above solutions, then pour 34.5644g of additive EDTA into the above mixed solution, place in a constant temperature magnetic stirrer, keep heating and stirring at 80°C-90°C for 1-2 hours, adjust the pH value with ammonia water until light yellow is formed Transparent sol, and then the solution is heated or aged to obtain a gel.

[0040] The gel obtained above was calcined at 1000° C. for 2 hours, and then calcined at 1200° C. in a reducing atmosphere for 2 hours to obtain a nano-luminescent powde...

Embodiment 2-4

[0042] Preparation of ultra-long afterglow luminescent material (sample 2-4)

[0043] According to the similar method described in Example 1, the difference lies in the use of the combination contents and preparation conditions shown in Table 1. As a result, the long-lasting luminescent material (sample 2-4) of the present invention was obtained.

[0044] Example 1

Embodiment 5

[0046] The performance measurement of the sample 1 prepared by embodiment 1

[0047] In this example, the dimensions and properties of the samples prepared in Example 1 were tested.

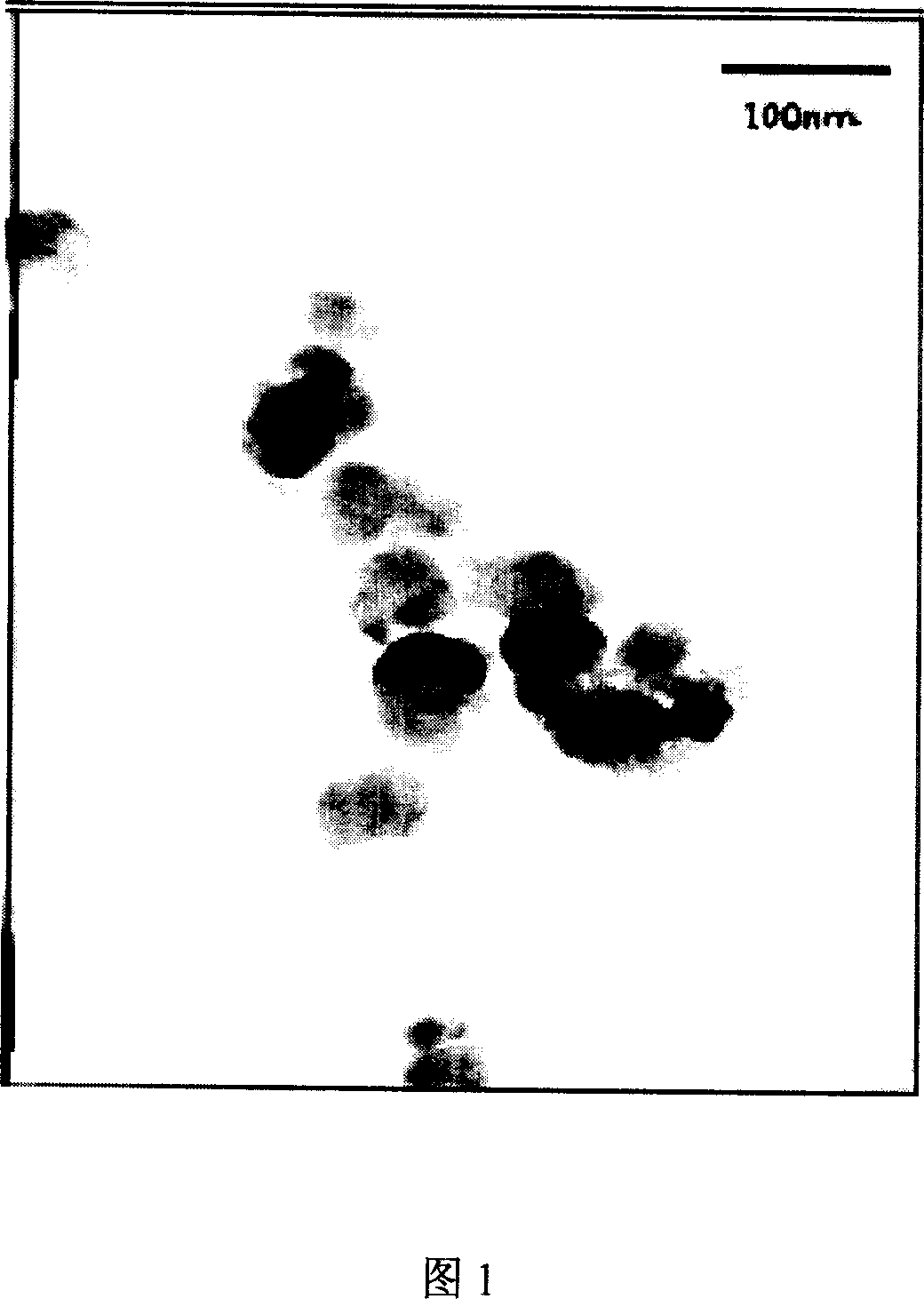

[0048] (1) Average particle size and composition

[0049] The average particle size was determined by TEM electron microscope. The results are shown in Figure 1, indicating that the particle sizes of the samples all reached the nanoscale.

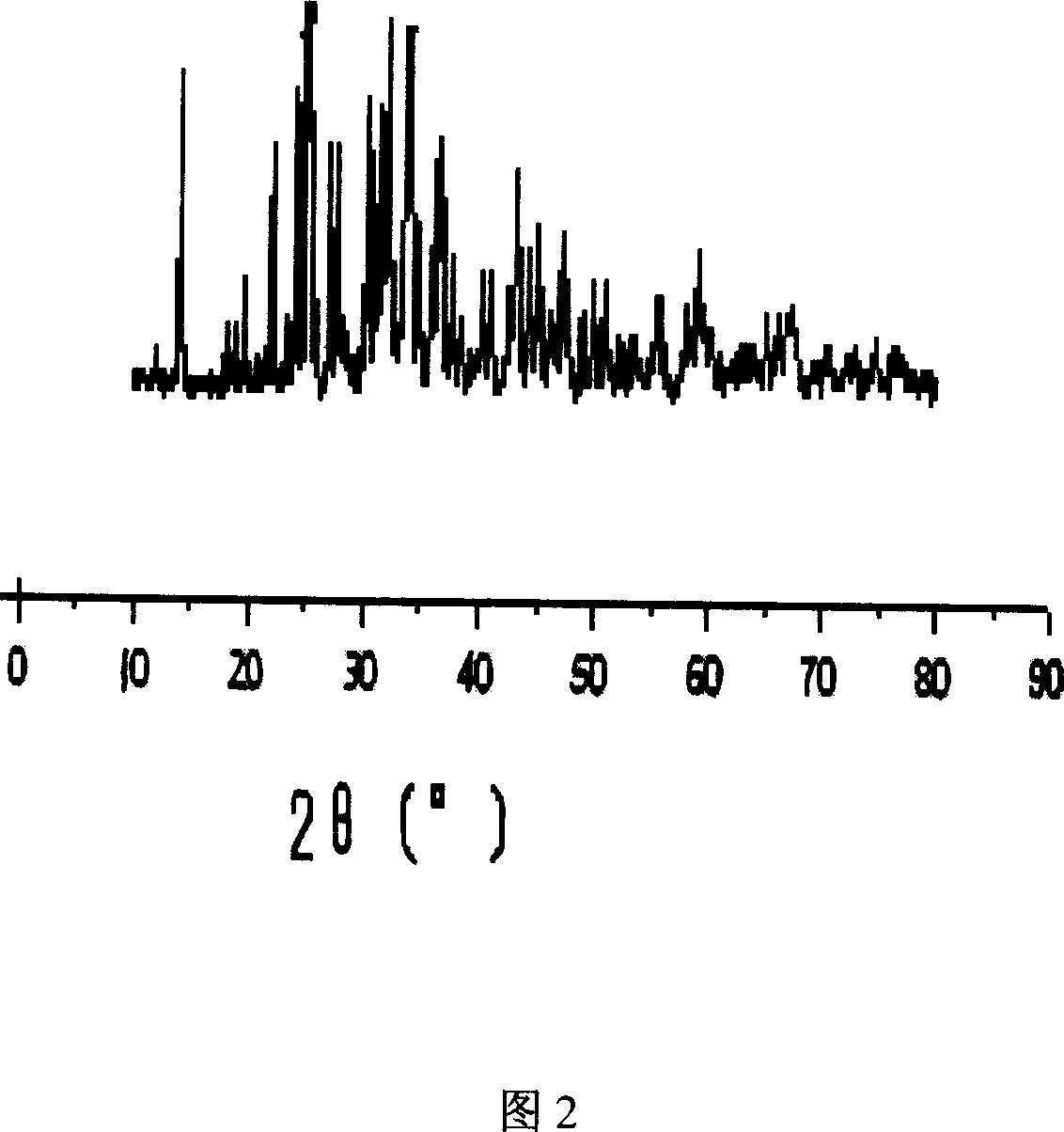

[0050] Its composition was determined by XRD powder diffraction method. The results are shown in Figure 2, indicating that the sample components meet the design requirements.

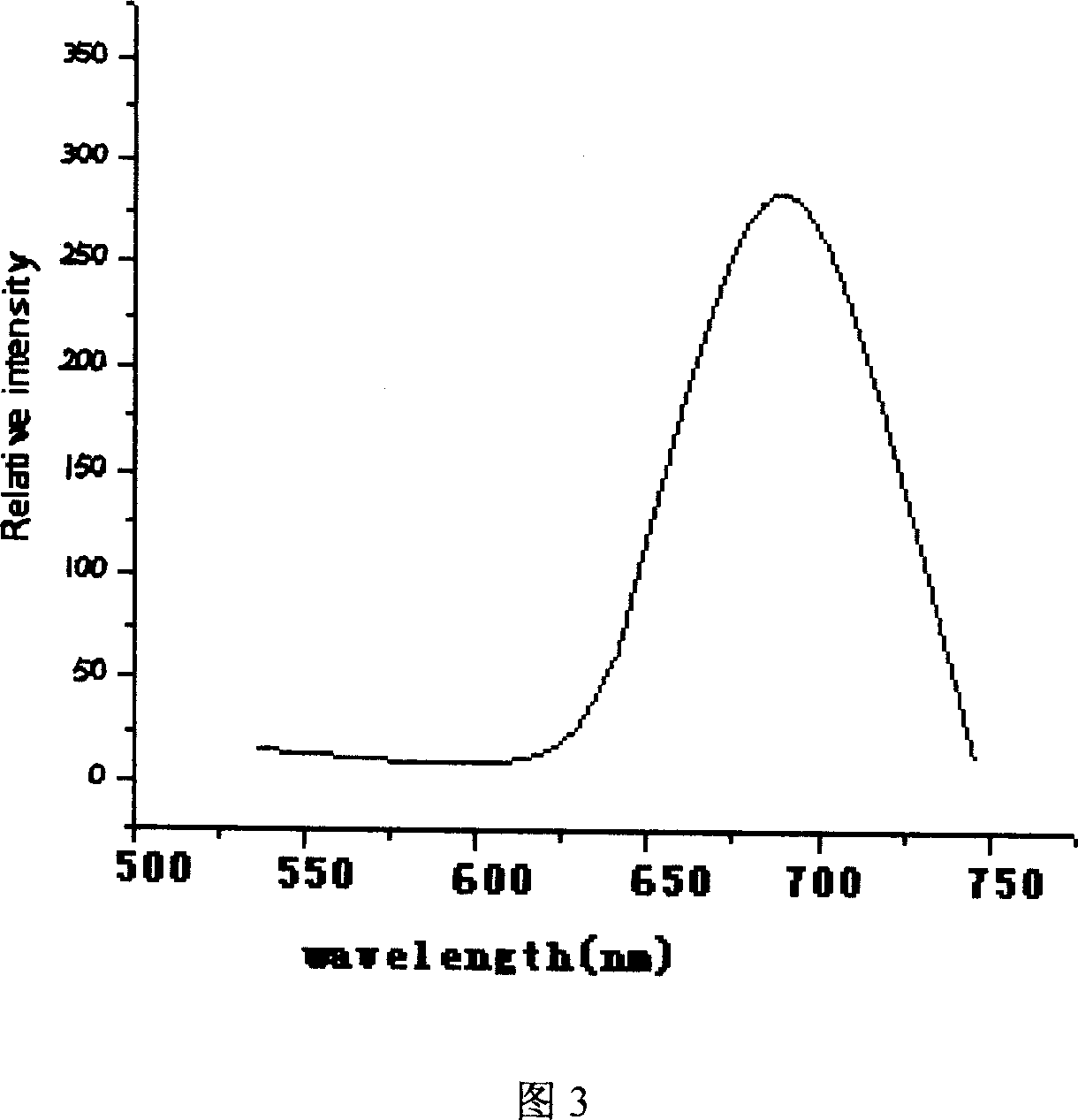

[0051] (2) Luminous properties

[0052] The result is shown in Figure 3. It shows that the sample wavelength and intensity meet the design requirements.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com