Method for cultivating edible mushroom and special tools

A cultivation method and edible fungus technology, applied in the directions of botanical equipment and methods, application, horticulture, etc., can solve the problems of many production links, low production efficiency, low tube forming rate, etc., to simplify the production process, improve production efficiency, The effect of high inoculation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

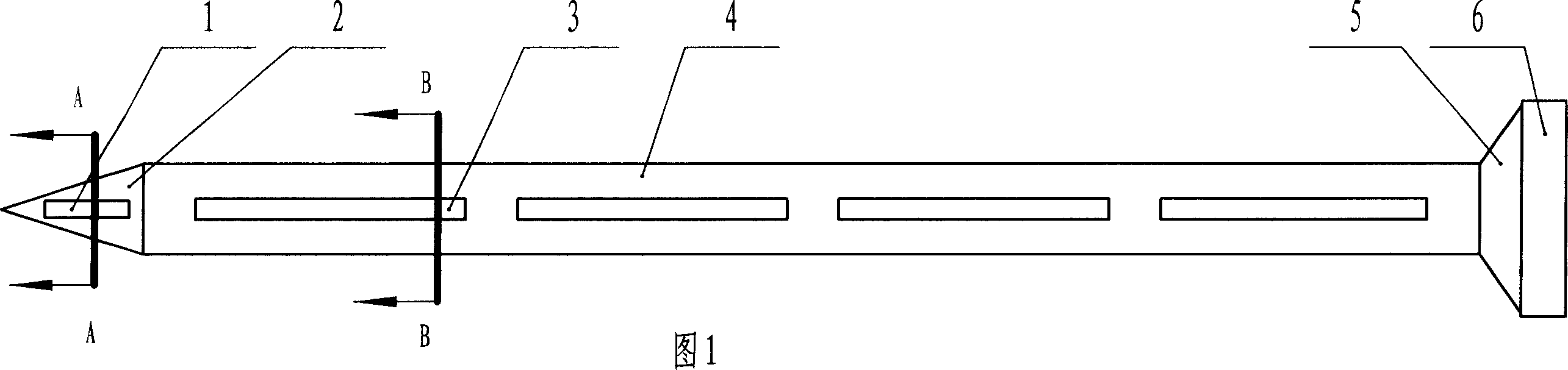

[0017] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

[0018] This embodiment includes the following steps:

[0019] (1) Feeding: Pack the mixed culture materials into bags, and then discharge them on the cultivation frame 10-20cm from the ground, among which the large cultivation bags (diameter 20-35cm, length 80-120cm) are placed vertically; small cultivation bags (diameter<20cm, length 50-120cm) stacked in a square shape, with a height of 80-120cm.

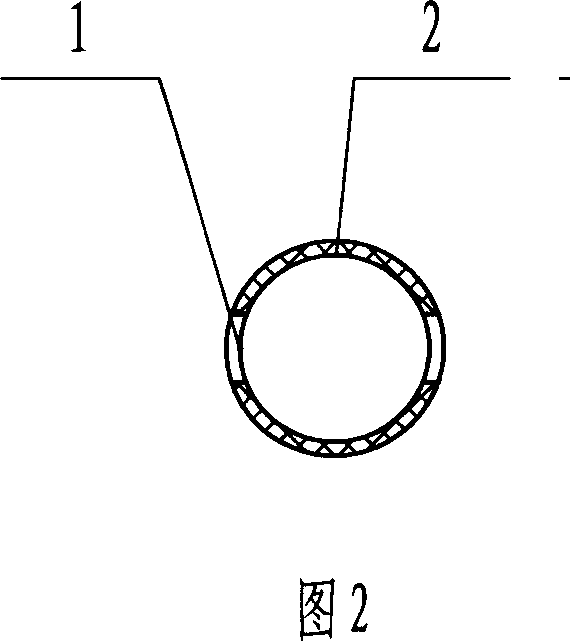

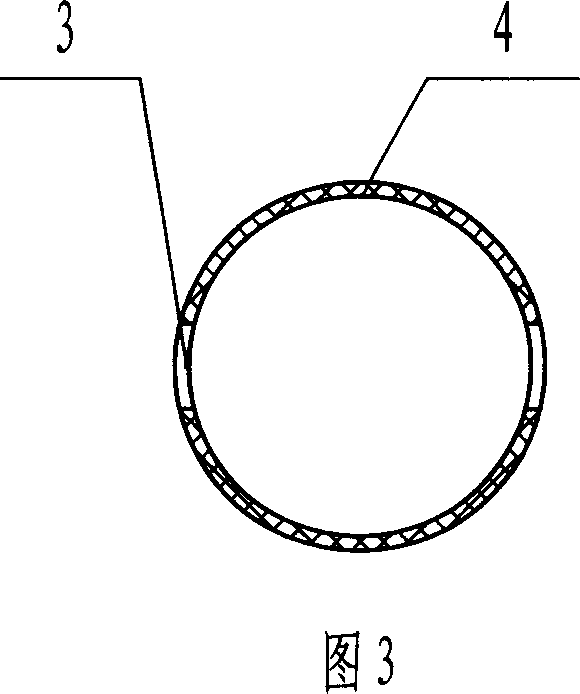

[0020] (2) Pre-set inoculation tube: insert an inoculation tube with the same length as the cultivation bag in the center of the cylinder of the large cultivation bag; insert an inoculation tube with the same length as the pile height at the intersection of the well-shaped stack of small cultivation bags.

[0021] (3) Sterilization: Use plastic film to cover the cultivation frame and the cultivation bags stacked on it, and then cover it with a lig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com