Fractional gasifying furnace for coal and coke gasification

A staged gasification furnace technology, applied in the manufacture of combustible gas, petroleum industry, combined combustion mitigation, etc., can solve the problems that the reaction conditions in the furnace cannot be optimized, and the oxygen distribution cannot be adjusted, so as to improve volume utilization and smooth flow , the effect of reducing space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

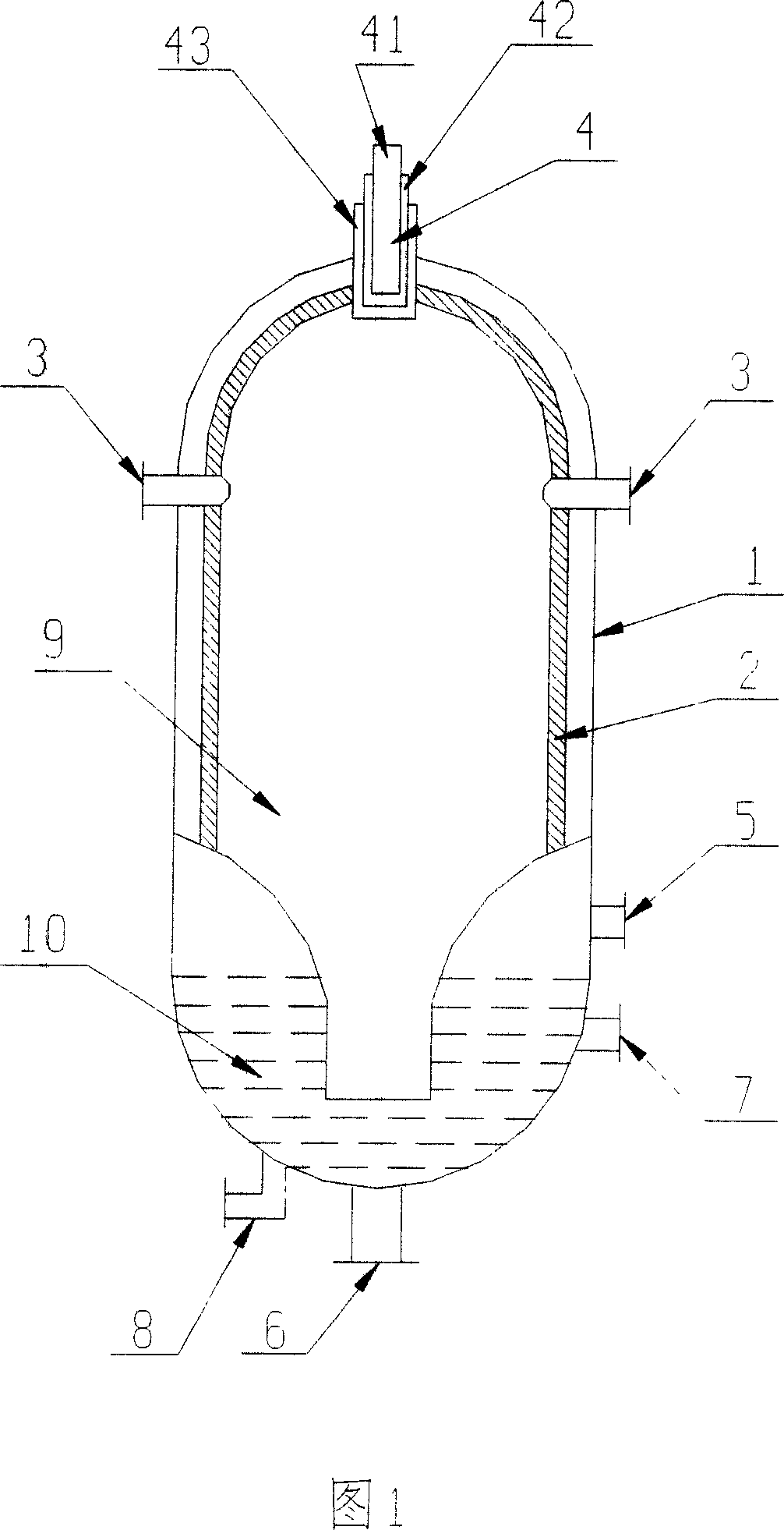

[0013] Embodiment 1: see Fig. 1. The staged gasifier for coal and coke gasification in this embodiment is composed of a steel pressure-resistant shell 1 and a refractory layer 2 therein, forming a furnace body 9 . The crude gas outlet 5 is installed at the lower part of the side wall of the pressure-resistant shell 1 , and the slag outlet 6 is installed at the bottom of the pressure-resistant steel shell 1 . A water quenching system 10 is provided at the lower part of the body of furnace 9, and the water quenching system 10 is equipped with a drain port 8 and a water replenishment port 7 at the lower part of the pressure-resistant casing 1. The present invention is characterized in that the secondary oxygen nozzle 3 is arranged at the On the side wall top of the pressure housing 1, there are preferably two secondary oxygen nozzles 3, as shown in the figure, symmetrically arranged on the pressure-resistant housing 1, and the position that the secondary oxygen nozzles 3 is set s...

Embodiment 2

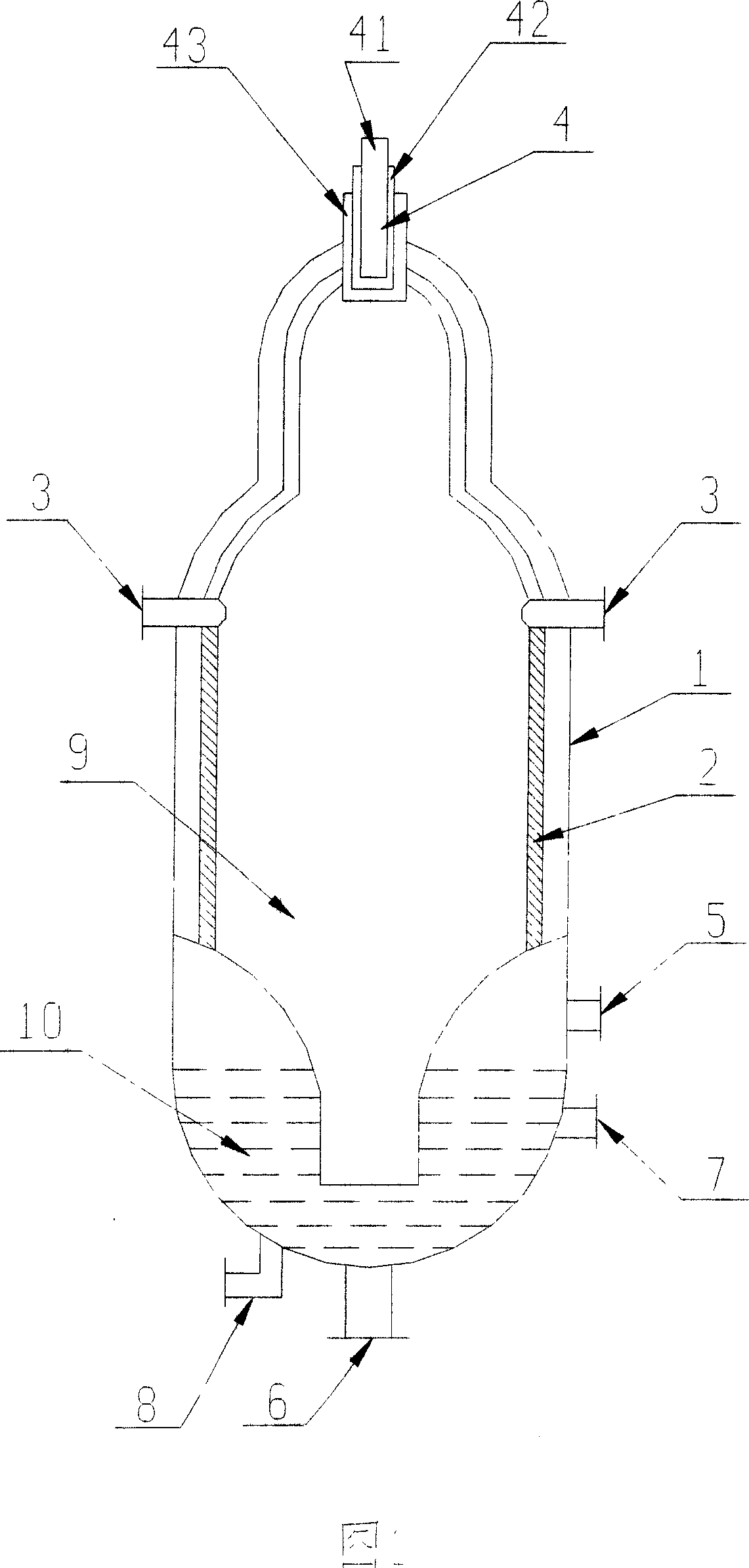

[0017] Embodiment 2: see Fig. 2. In the staged gasifier for coal and coke gasification in this embodiment, the upper low-temperature non-slag zone and the lower high-temperature slag zone are directly connected with unequal diameters, and the diameter of the upper low-temperature non-slag zone is smaller than the lower high-temperature slag zone. For example, according to the position of the recirculation zone, the recirculation zone and the following parts are set to a larger diameter, which is convenient for better temperature control according to the fuel properties. The other structures of this embodiment are the same as those of Embodiment 1.

Embodiment 3

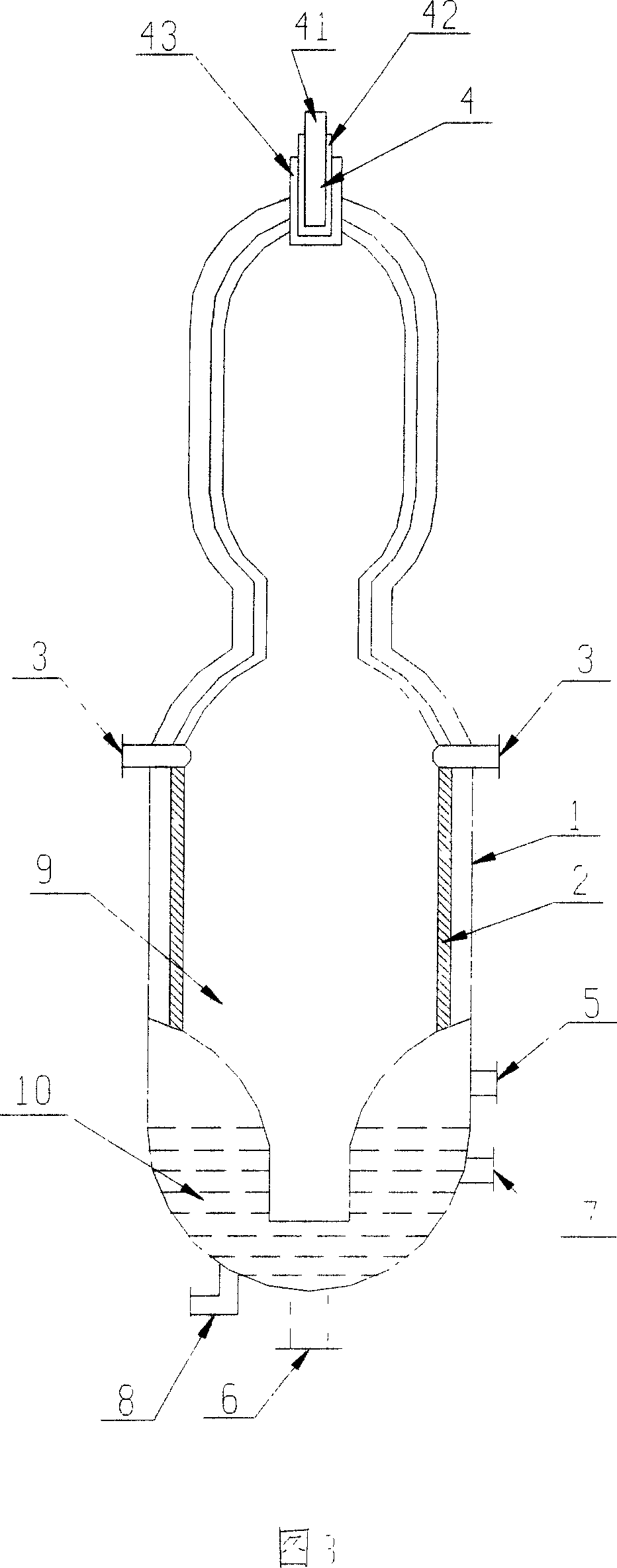

[0018] Embodiment 3: see Fig. 3. In the staged gasifier for coal and coke gasification in this embodiment, the upper low-temperature non-slag zone is connected with the lower high-temperature slag zone in reduced diameter. The upper low-temperature non-slag zone of this structure has a longer space area, which is suitable for higher calorific value. Low raw fuel can provide a larger and more sufficient primary gasification space, making it close to the slag temperature of 1000 °C. Other constructions of this example are the same as Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com