Four stroke top placed cam-type engine

An overhead cam, four-stroke technology, which is applied to engine components, machines/engines, valve devices, etc., can solve the problem of unfavorable heat dissipation of the lightweight cylinder head of the engine, and achieve the advantages of cooling, improving heat dissipation, and reducing sealing surfaces. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

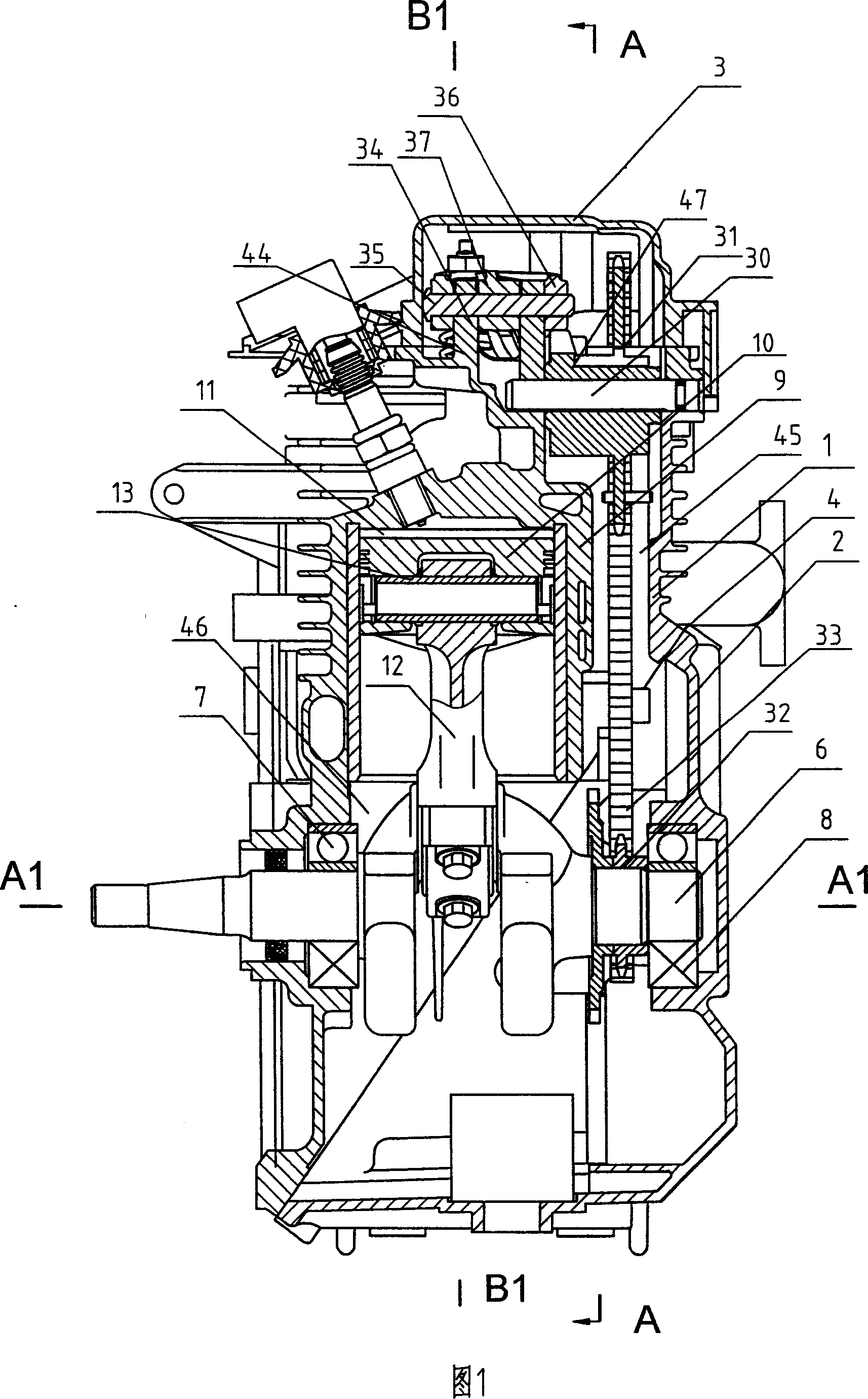

[0024] Embodiment 1: (the intake and exhaust valves share one cam)

[0025] The invention is a single-cylinder air-cooled overhead cam gasoline engine. The engine main parts body 1, crankcase cover 2 and cylinder head cover 3 are molded by aluminum alloy or magnesium alloy. The body 1 and the crankcase cover 2 are obliquely divided at the joint surface 4 and connected with multiple sets of bolts 5 . The connecting surface 4 of the body 1 and the crankcase cover 2 passes through the crankshaft axis A1-A1 and the cylinder axis B1-B1. The rotation of crankshaft 6 is to pass through bearing 7 and bearing 8 at both ends, bearing 7 is supported on the body machine 1, and bearing 8 is supported on the crankcase cover 2.

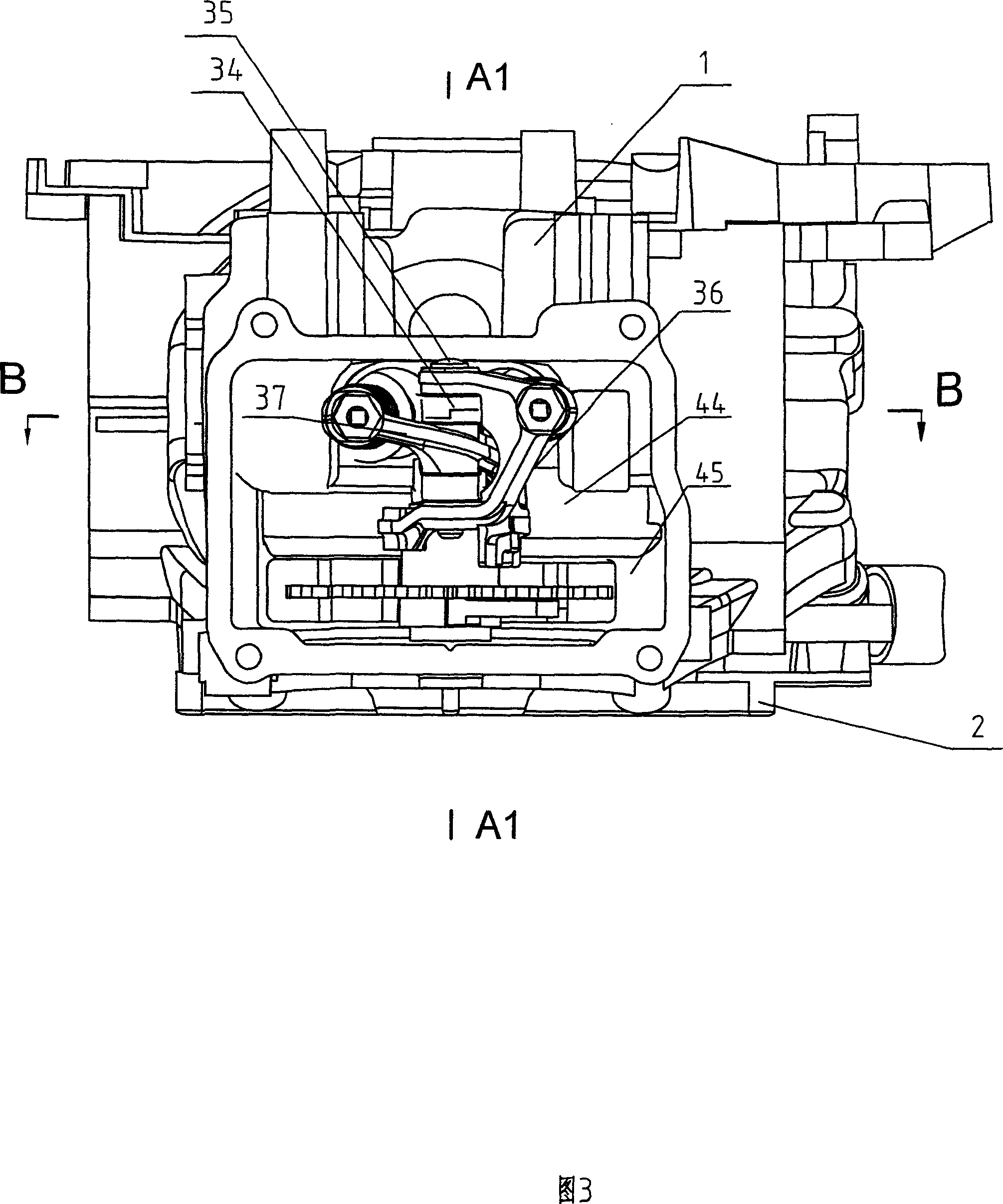

[0026] The engine body 1 is formed by the cylinder head 44, the upper crankshaft half case 46, the cylinder barrel 9, and the chain chamber 45 by bolts. The cylinder head cover 3 is fixed on the cylinder head 44, and the piston 10 is installed in the cylinder barre...

Embodiment 2

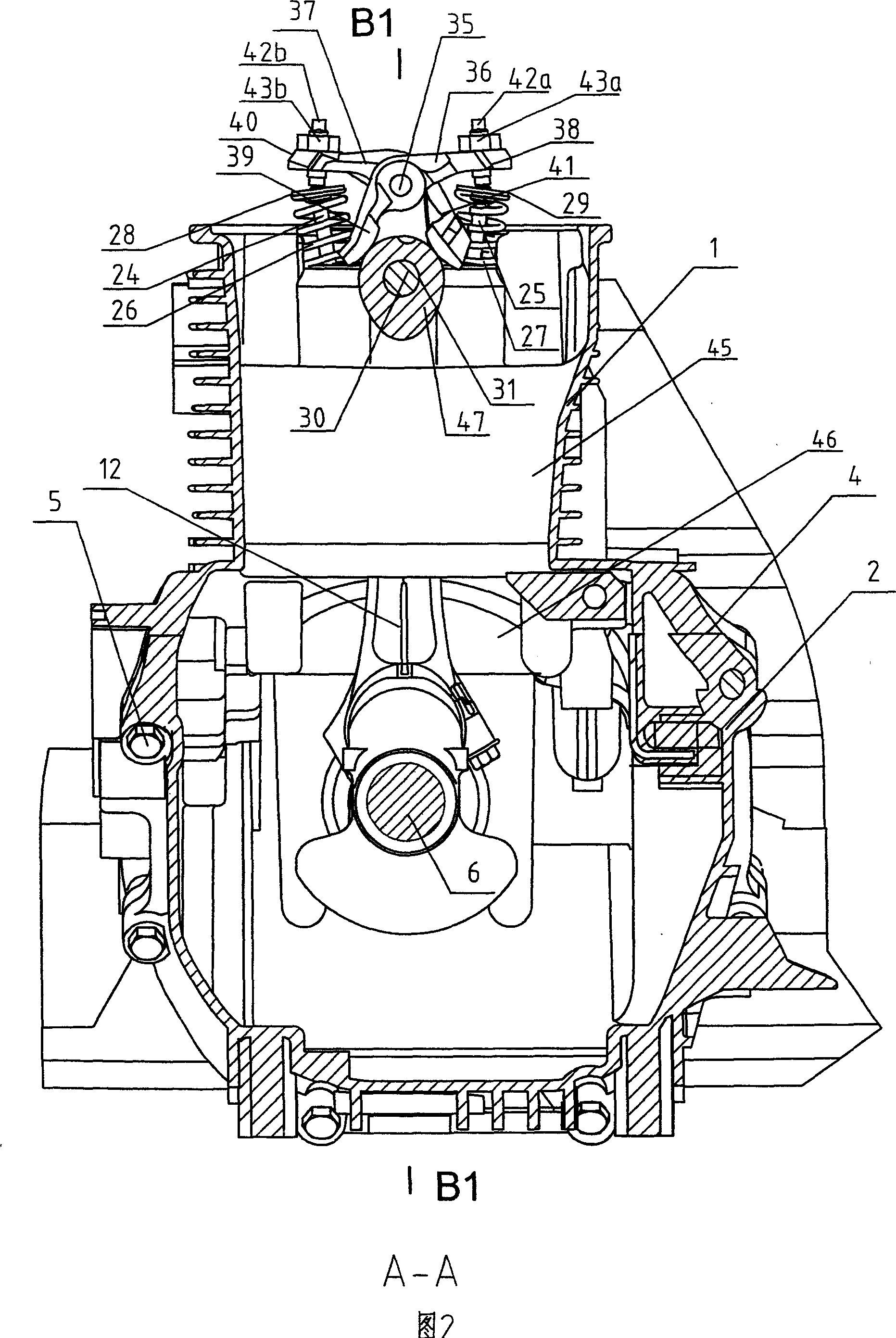

[0032] Embodiment two: (intake and exhaust valve use a cam respectively)

[0033] The engine body 1 is combined to form a whole by the cylinder head 44, the cylinder barrel 9 that accommodates the piston, the chain chamber 45, and the upper crankshaft half case 46. The top of the cylinder barrel 9 on the body forms a combustion chamber 11, and the spark plug 48 is used here for timing. Fire into the combustion chamber.

[0034] The upper part of the body 1 also has an air intake channel 14 and an exhaust channel 15 formed by casting in advance, and the air intake channel 14 and the exhaust channel 15 are respectively located on both sides of the cylinder axis B1-B1. One end of the intake duct 14 leads to the combustion chamber 11, and an intake valve seat 16 is press-fitted at the junction, and the other end forms a plane outside the body 1 . One end of the exhaust passage 15 also leads to the combustion chamber 11, and an exhaust valve seat 17 is press-fitted at the junction...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com