Online energy source predicting system and method for integrated iron & steel enterprise

An energy and enterprise technology, applied in the field of iron and steel energy forecasting, can solve problems such as large errors, slow convergence speed, and failure to provide an energy analysis process, and achieve the effects of easy expansion, improved accuracy and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

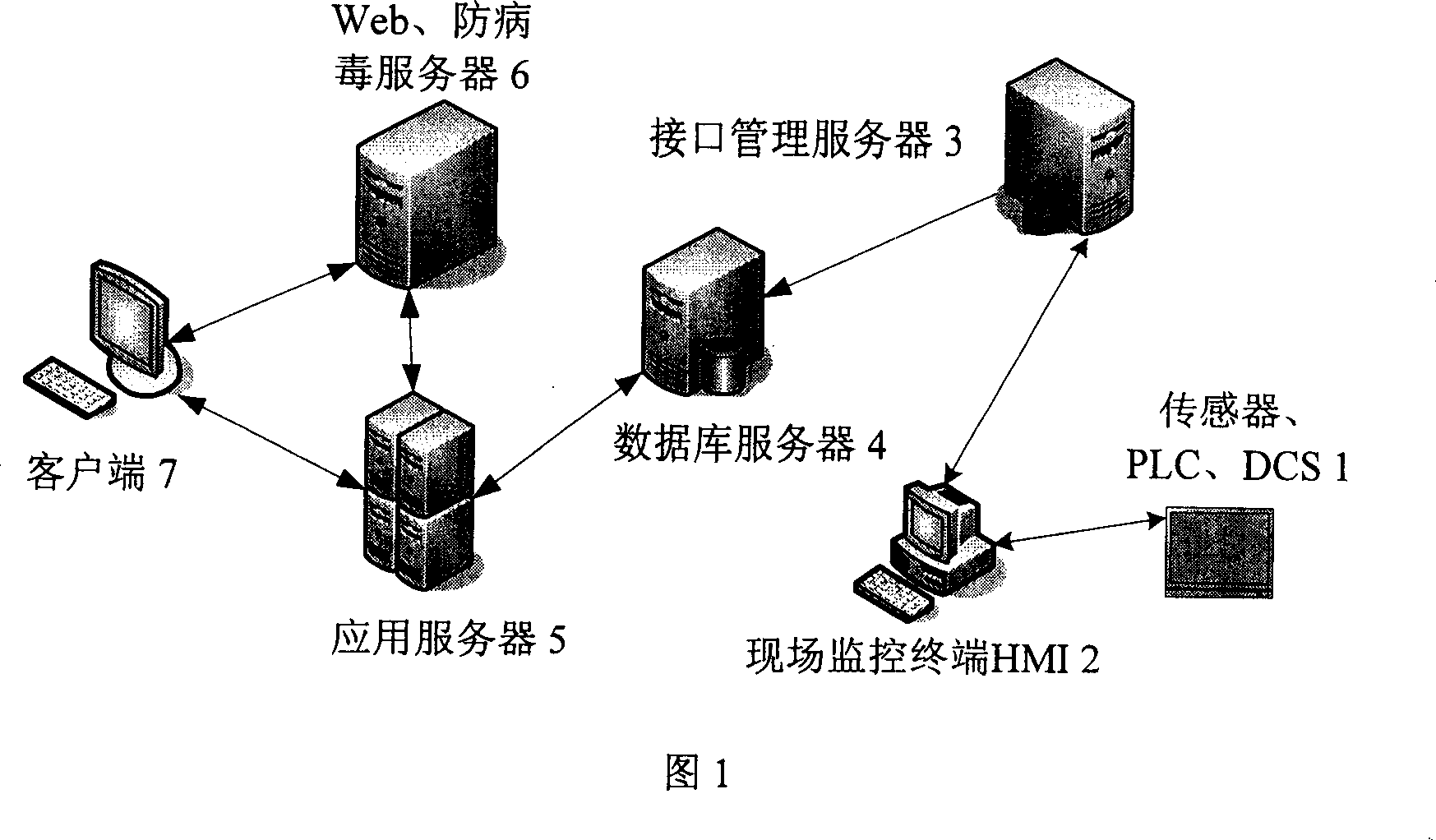

[0045] 1) To build an enterprise information network, the PCS layer is composed of on-site sensors, PLC, and DCS 1; on-site monitoring terminal HMI 2; interface management server 3; database server 4; application layer server 5; Web, anti-virus server 6; Terminal workstation 7; And each computer equipment etc. is connected into computer network.

[0046] 2) The PCS layer composed of on-site sensors, PLC, and DCS 1 and the on-site monitoring terminal HMI 2 are responsible for on-site control and data collection, and collect data into the interface management server 3 and database server 4 .

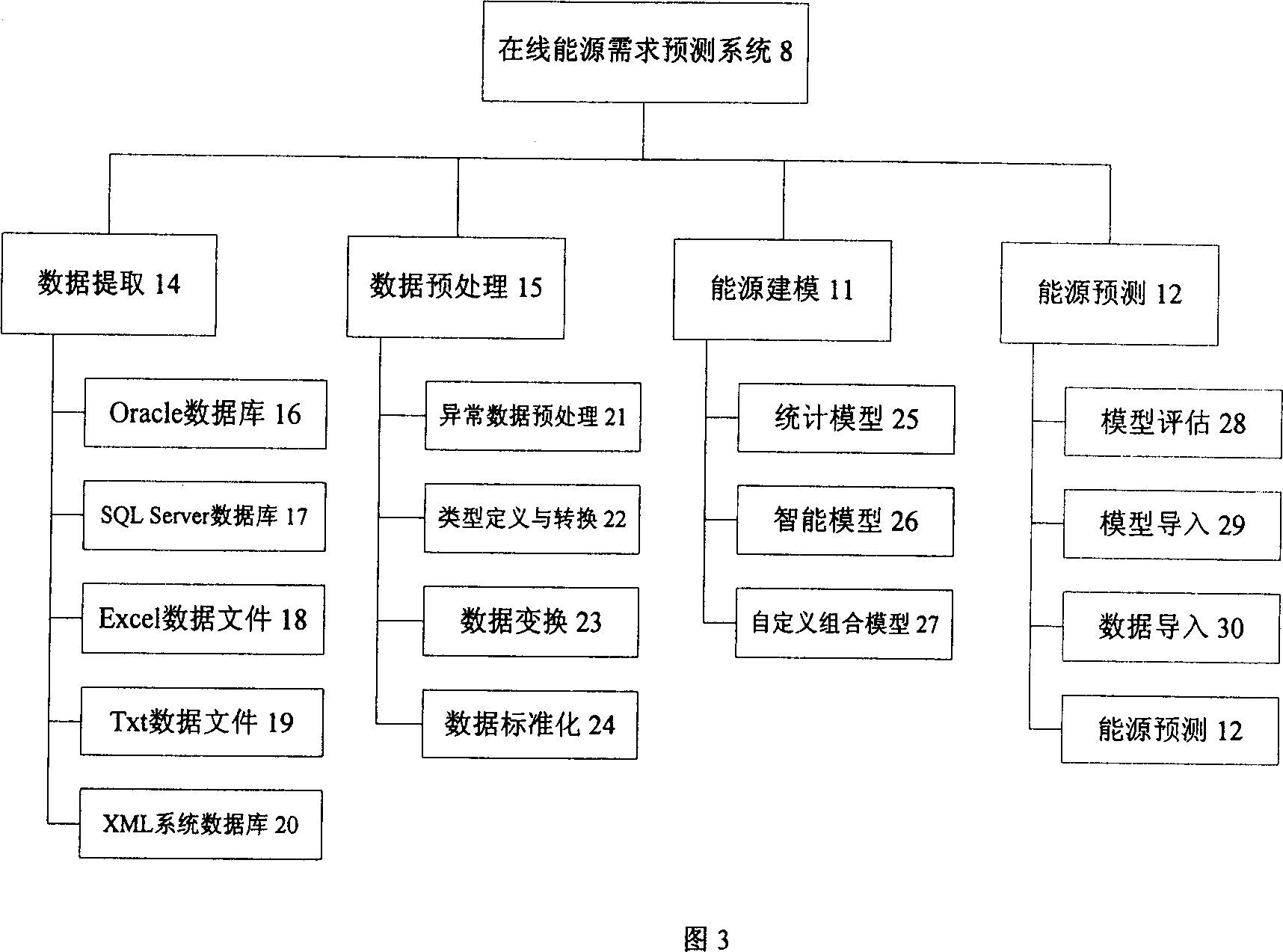

[0047] 3) utilize multiple data extraction 14 (Oracle database 16, SQL Server database 17, Excel data file 18, Txt data file 19, XML system database 20) method that the present invention provides, extract relational data table or local data in the database server file, select a suitable extraction method, extract energy demand forecast data sources, and prepare for subsequent analysis.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com