Petroleum hydrocarbon cracking carbon nine cut fraction hydrogenation technology

A technology for cracking carbon and petroleum hydrocarbons, which is applied in the fields of hydrotreating process, petroleum industry, and hydrocarbon oil treatment. The liquid distribution is reasonable and the effect of improving the effective utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] The catalyst used was supported on Al 2 o 3 -SiO 2 Ni-based catalysts. Catalyst specific surface area 180m 2 / g, the pore volume is 0.5ml / g, and it is a bimodal pore catalyst.

[0024] The composition of cracked carbon nine: the content of methyl styrene, styrene and other alkenyl aromatics and indene is 36%, the content of dicyclopentadiene is 32%, the content of tea is 3%, and the content of monoolefins, alkanes and others is 29%. The density is 0.948g / ml, the distillation range is 118~228℃, and the colloid is 4000mg / 100ml.

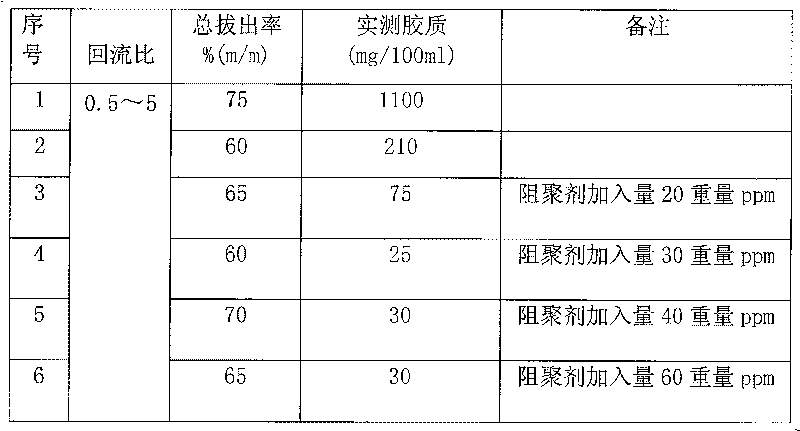

[0025] The above-mentioned part of the cracked carbon nine is treated by pressure thermal polymerization, the thermal polymerization pressure is 0.5-1.6Mpa, the temperature is 120-260°C, and the time is 8-20h. The composition of the flash oil produced: the content of methyl styrene, styrene and other alkenyl aromatics and indene is 7.8%, the content of dicyclopentadiene is 6.5%, and the content of monoolefins, alkanes and others is 85.7%; th...

Embodiment 2

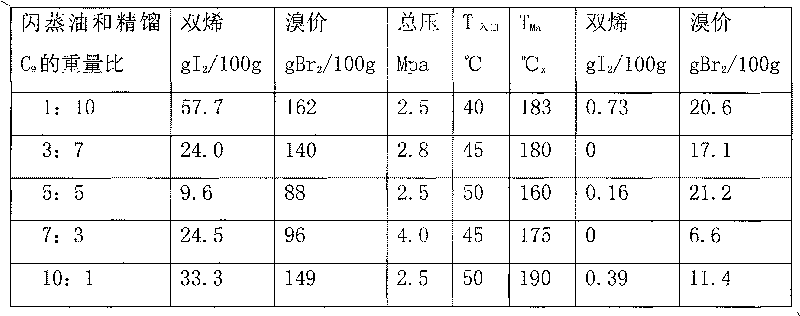

[0035] Catalyst, flash oil are the same as embodiment 1, and rectification carbon nine adopts the product of table 1 serial number 5 of embodiment 1. In the 20,000-ton / year cracking C9 hydrogenation industrial unit, an upflow bubbling bed reactor is used for hydrogenation, and the colloid after mixing the flash oil and the rectified C9 is controlled at -1 . The results are shown in Table 3 and Table 4.

[0036] Table 3 Reactor bed temperature distribution

[0037]

[0038] Table 4 Composition analysis before and after hydrogenation

[0039]

[0040] The data in Table 3 shows that the temperature distribution of the hydrogenation reactor is reasonable, and no hot spots are gathered, which proves that the total space velocity is between 3.0 and 4.0h when processing high-impurity C9 raw materials -1 Under these conditions, the gas-liquid distribution in the reactor is good without channeling and local overheating.

[0041] The data in Table 4 shows that the rectified C9 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com