Energy feedback power unit

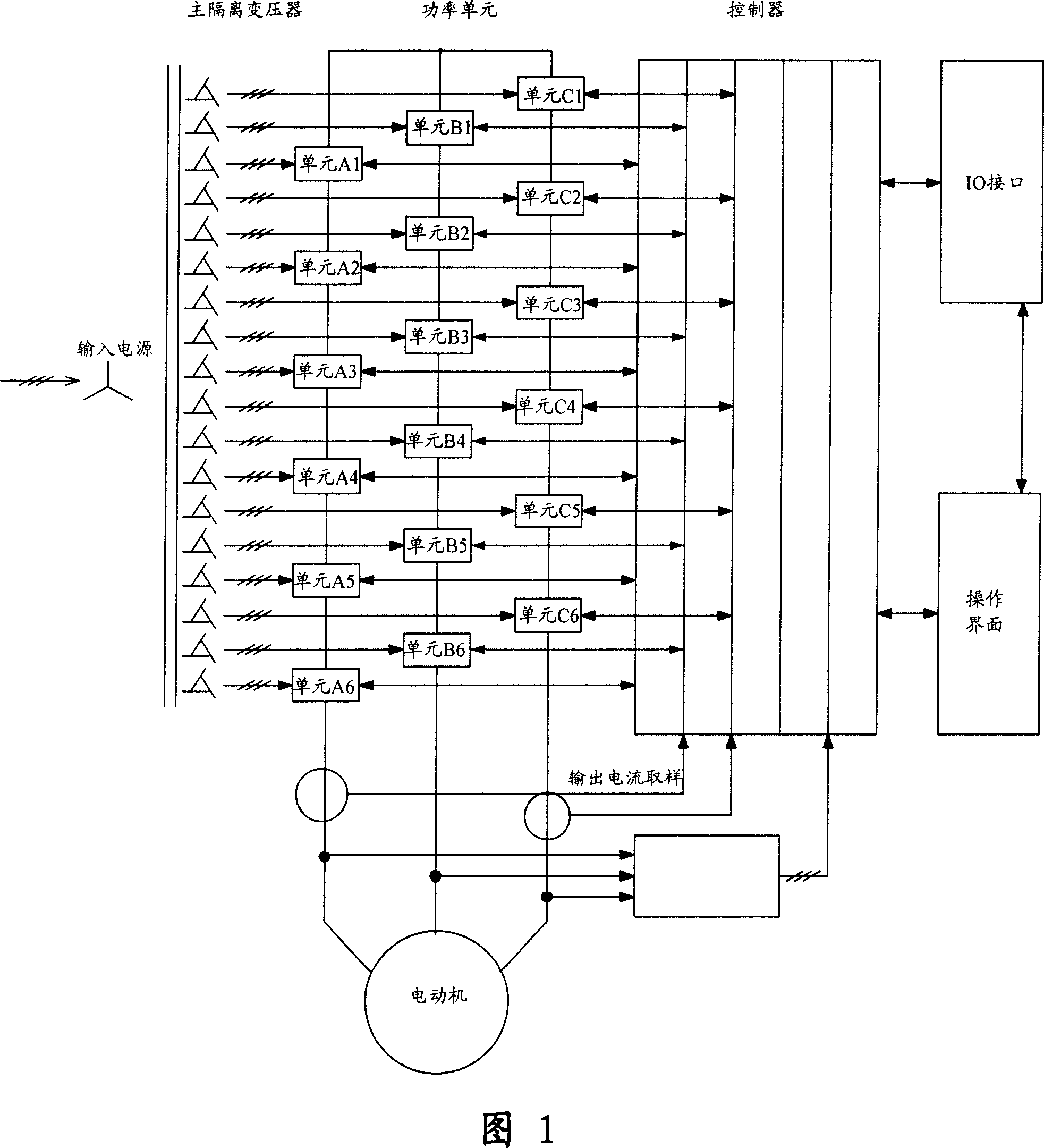

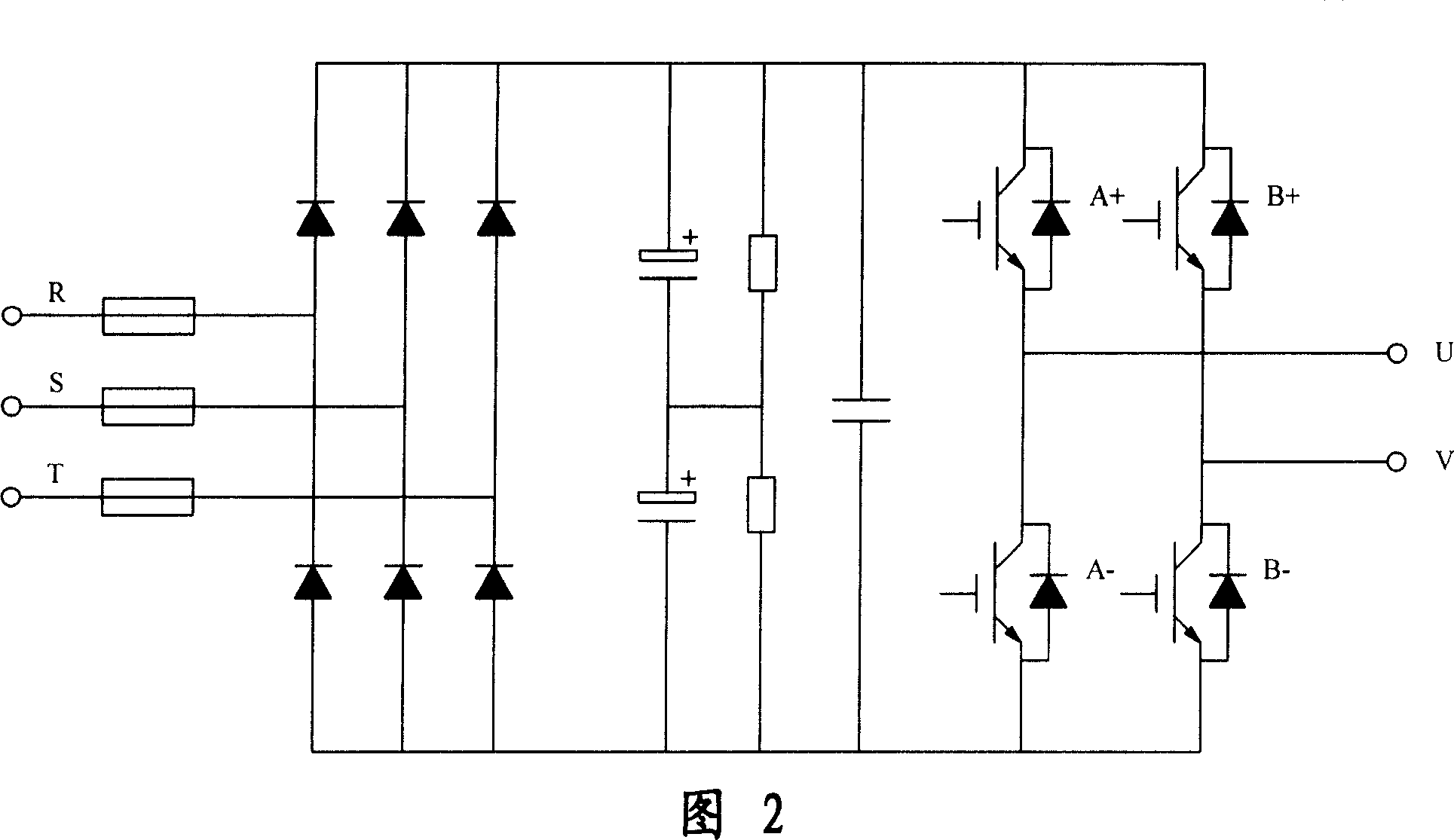

A technology of power unit and energy feedback, which is applied in the direction of output power conversion device, conversion of AC power input to AC power output, conversion of AC power input to DC power output, etc. Complicated structure and other problems, to achieve good promotion and application prospects, reduce harmonic pollution, and simple device structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings.

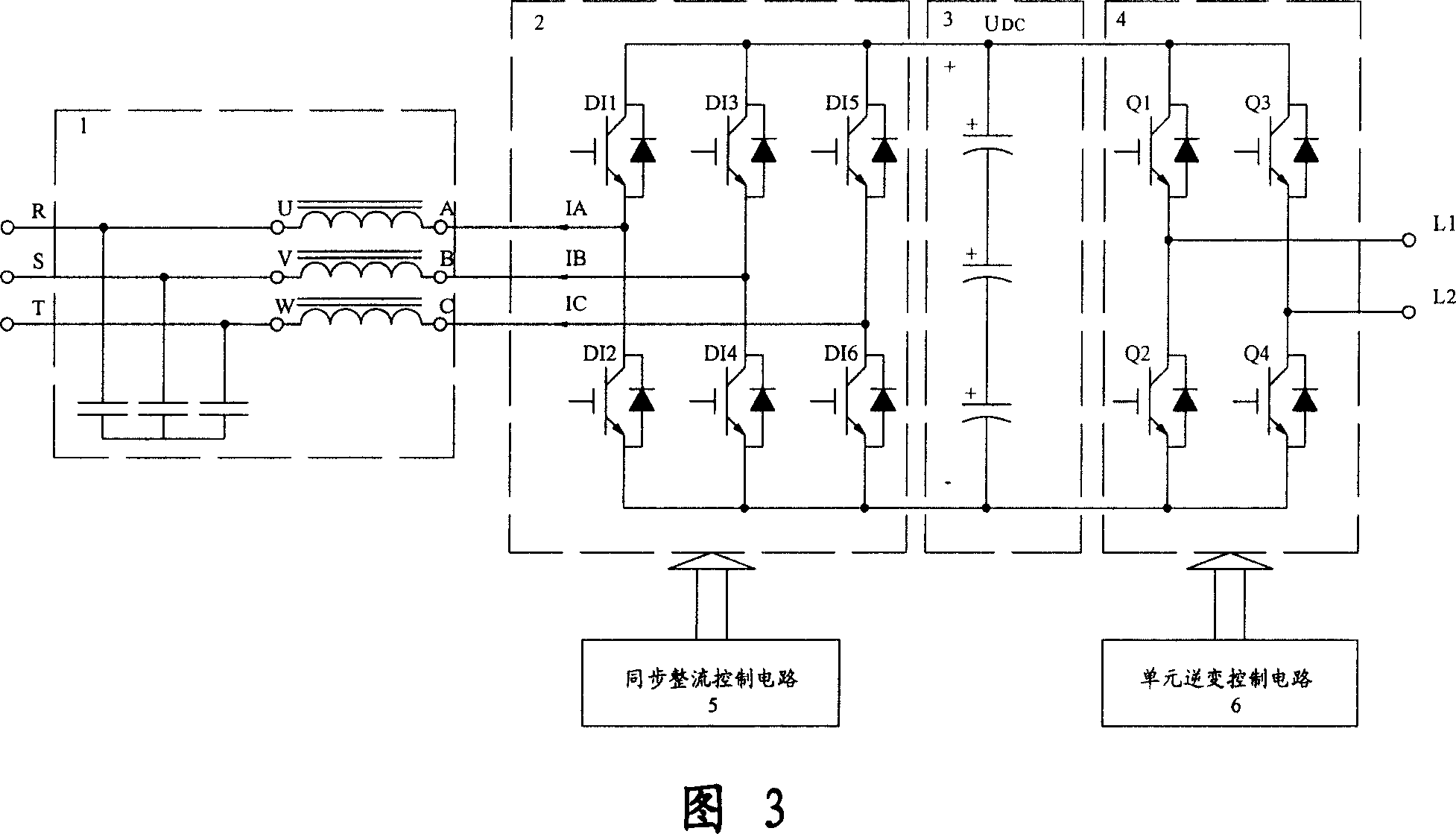

[0024] Referring to Fig. 3, the control circuit composition structure of the energy feedback power unit of the present invention is introduced: a filter circuit 1 composed of a three-phase capacitor and a three-phase reactor connected in sequence, a three-phase synchronous rectification bridge composed of an insulated gate bipolar transistor IGBT 2. A DC filter circuit 3 composed of capacitors, a unit inverter bridge 4 composed of IGBTs, and a synchronous rectification control circuit 5 and a unit inverter that respectively control the working states of the three-phase synchronous rectification bridge 2 and the unit inverter bridge 4 variable control circuit 6; wherein two control circuits 5 and 6 are the innovation key of the device of the present invention: the u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com