Double clad optical fibre passive Q-switched laser

A double-clad fiber and laser technology, applied in the field of lasers, can solve problems such as high cost and complex structure, and achieve the effects of low cost, small size, and easy adjustment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

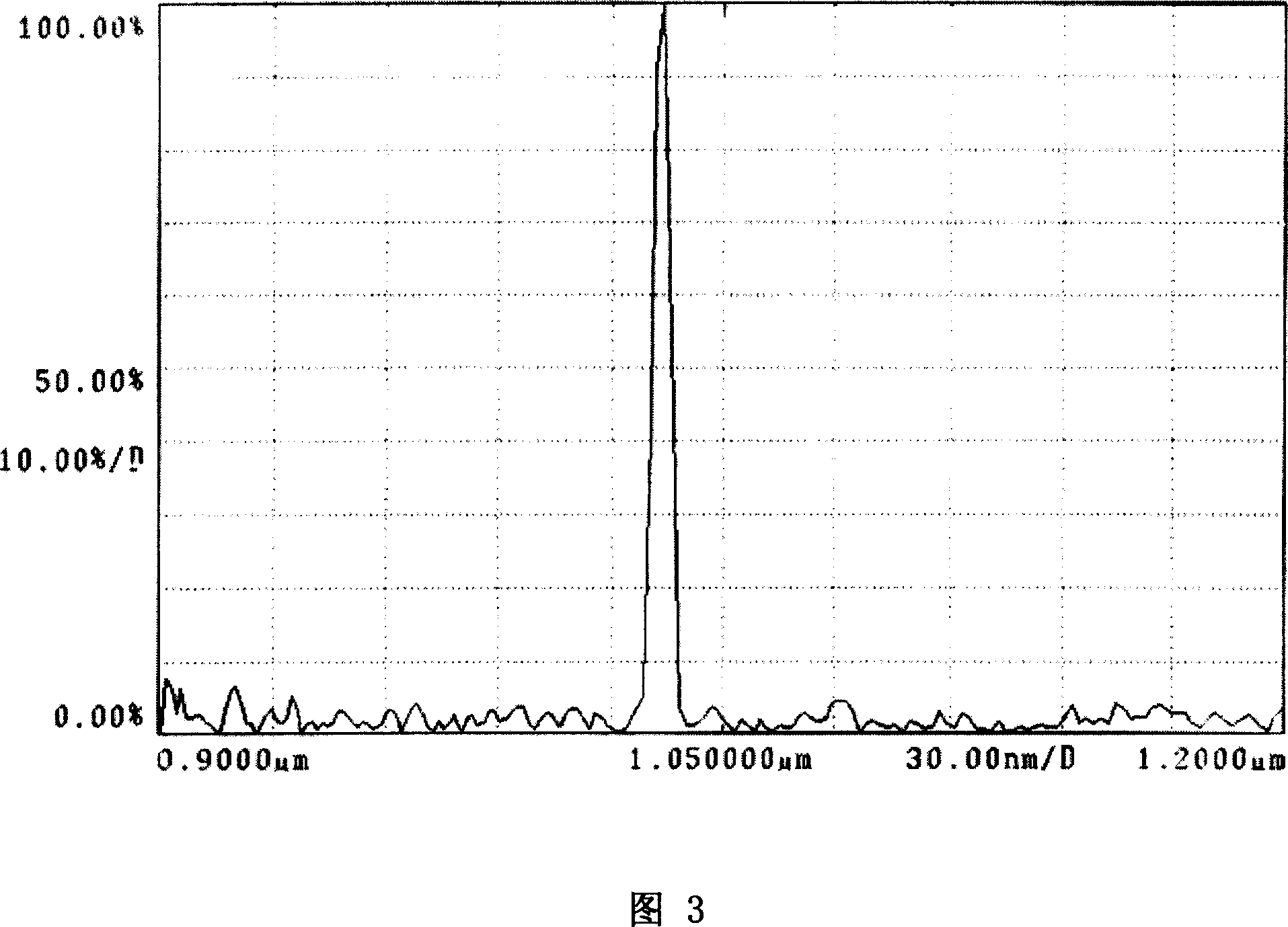

[0018] The invention integrates the cladding pumping technology and the Q-switching technology, utilizes the saturable absorption Q-switching characteristic of the semiconductor saturable absorber mirror to form a Q-switching pulse, and the semiconductor saturable absorber mirror also serves as a coupling output mirror.

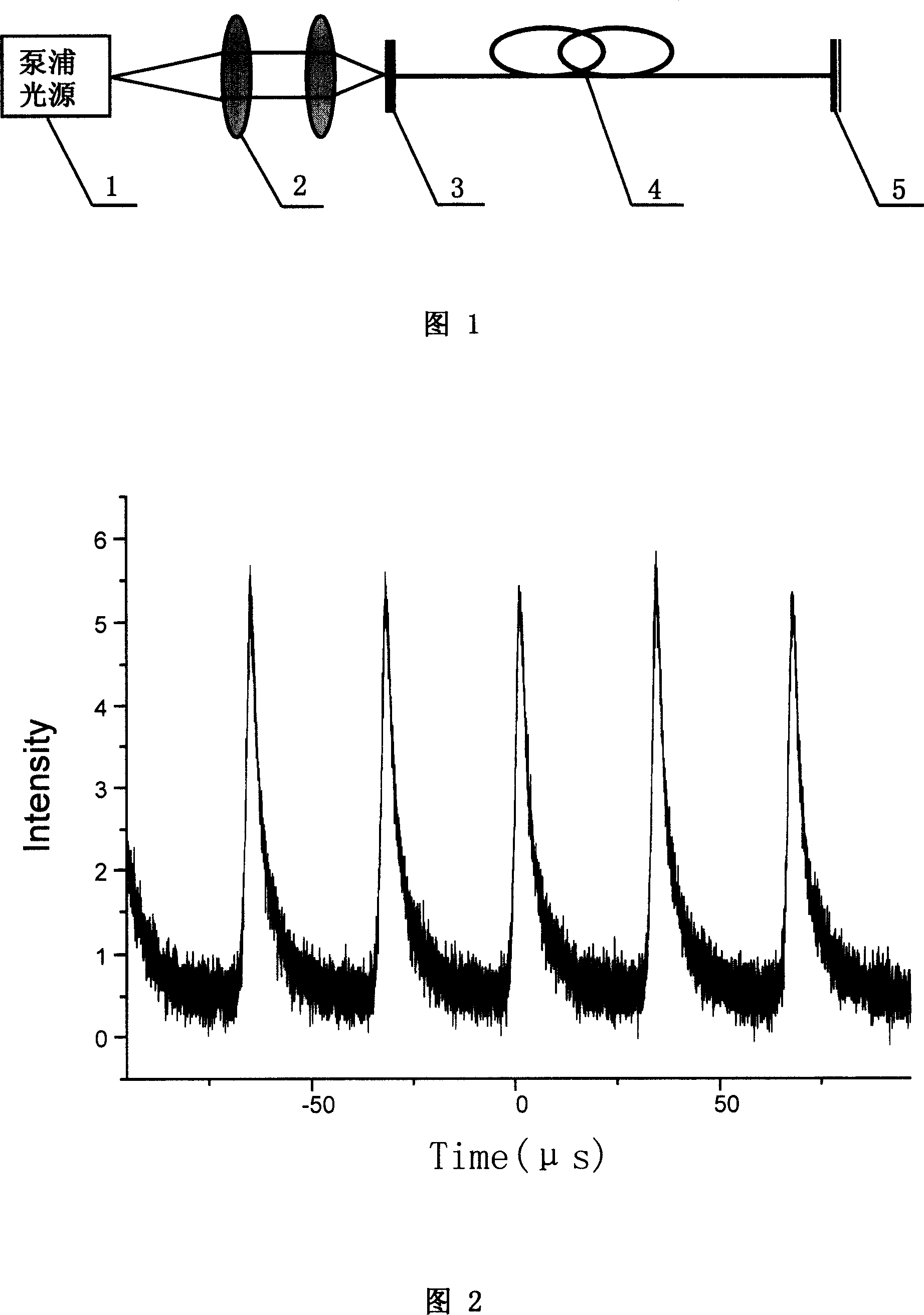

[0019] The pumping light source 1 of the present invention adopts a semiconductor 980nm pumping light source. The resonant cavity is composed of a front cavity mirror 3 , a double-clad ytterbium-doped fiber 4 and a Q-switching device 5 . The resonant cavity has a simple cavity structure, is suitable for adjustment, and has high light-to-light conversion efficiency. The front cavity mirror 3 can be a dichroic mirror coated with an antireflection film for a wavelength of 980nm and a highly reflective dielectric film for a wavelength of 1060nm. The double-clad ytterbium-doped fiber 4 can be a double-clad fiber with an outer cladding aperture of 0.40, a cladding...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com