Power driven and braking equipment of pressing machine driven by servomotor directly

A servo motor and power transmission technology, applied in the field of presses, can solve the problems of noise pollution of operators and the surrounding environment, high maintenance costs, complex structure, etc., and achieve the effects of good braking, maintenance cost saving, and good maintainability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

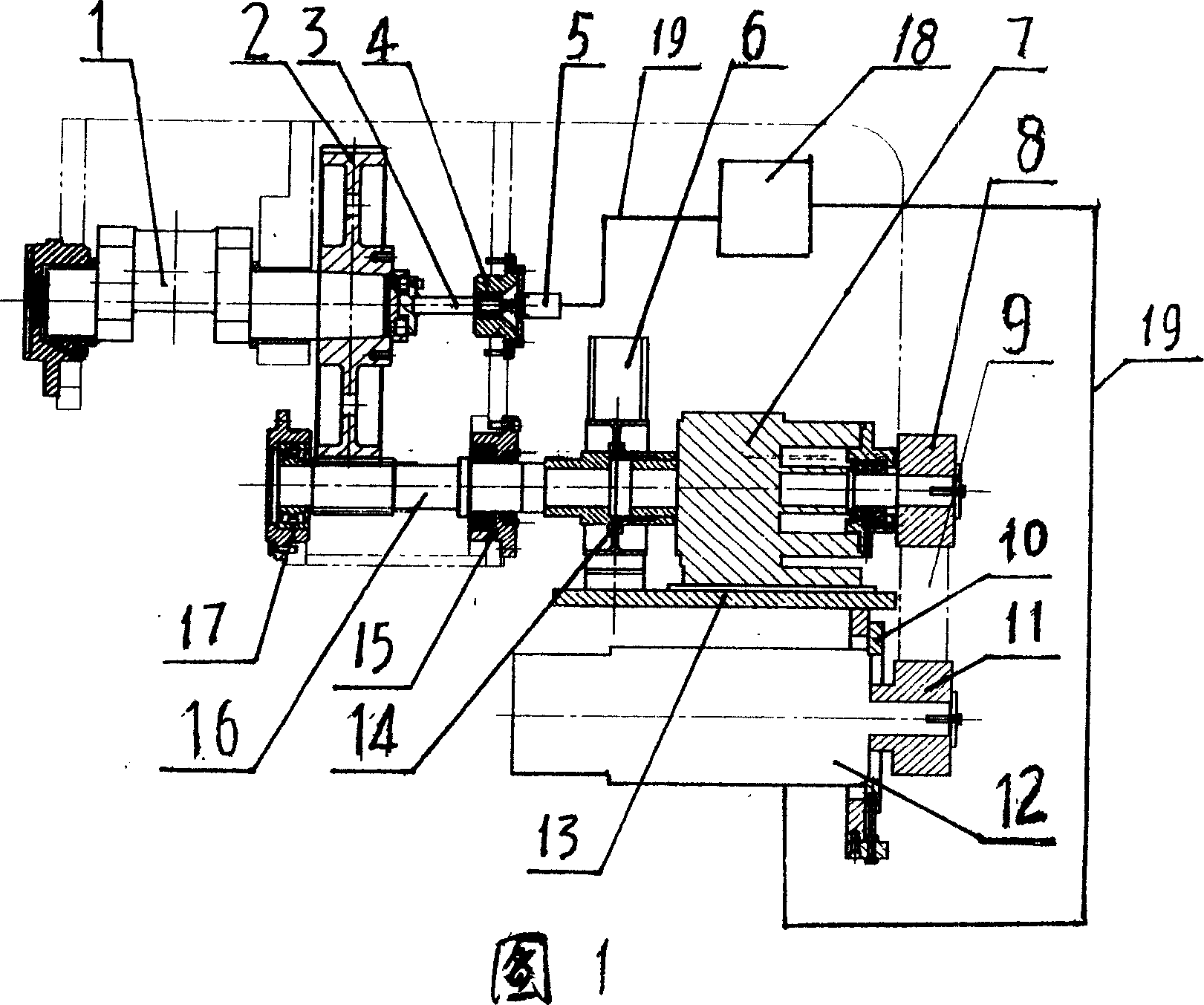

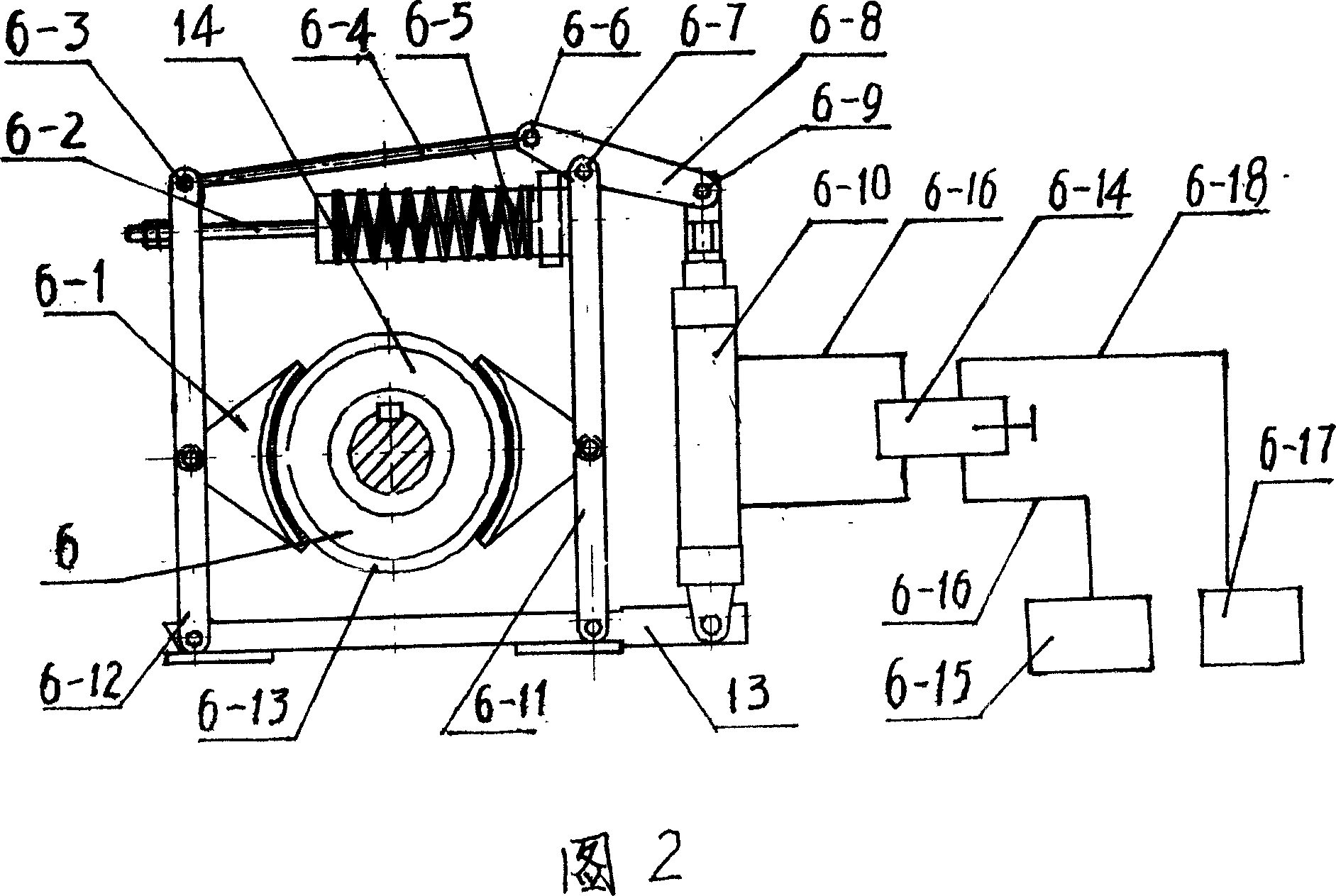

[0012] As shown in Figure 1, the servo motor 12 installed at the bottom of the fuselage 13 transmits power to the reduction box 7 installed on the fuselage 13 through the pulley 11, the pulley 8 and the belt 9. The coupling 14 of 6 transmits the power to the gear shaft 16, and the gear shaft 16 is coaxially installed on the fuselage through the bearing housings 15 and 17. The gear shaft 16 and the gear 2 are meshed to realize the second stage of deceleration to drive the crankshaft 1 to rotate. The crankshaft drives the slider to move up and down to complete the stamping function. The end of the crankshaft 1 is coaxially fixed to the encoder output shaft 3, which is connected with the resolver 5 installed in the resolver seat 4 on the fuselage, and the resolver 5 inputs the rotation signal of the crankshaft to the encoder 18 through the signal line 19, After being processed by the encoder 18, the signal is input to the servo motor 12 to control the start and stop of the servo ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com