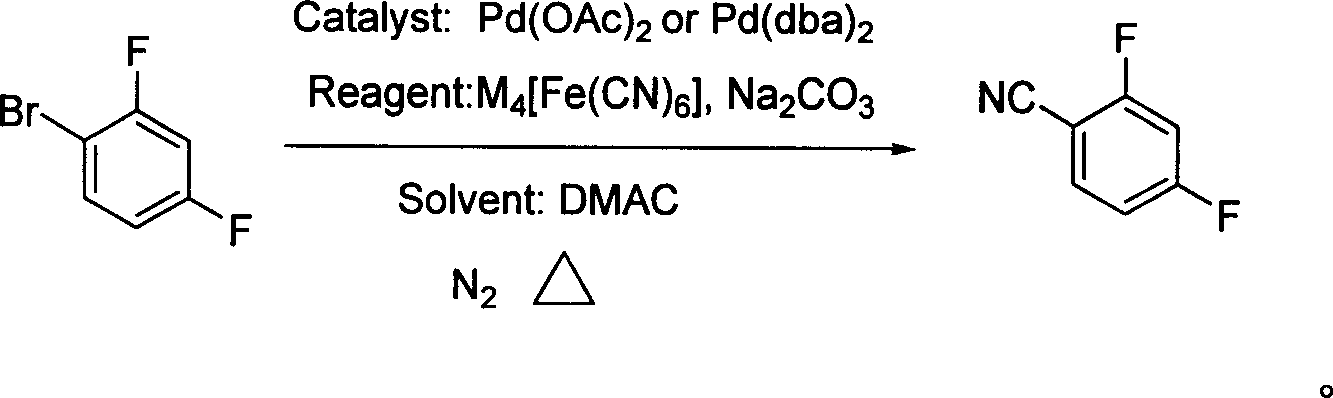

Process for preparing 2,4-difluorocyanobenzene

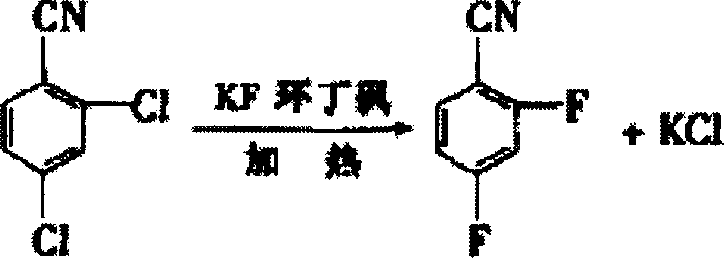

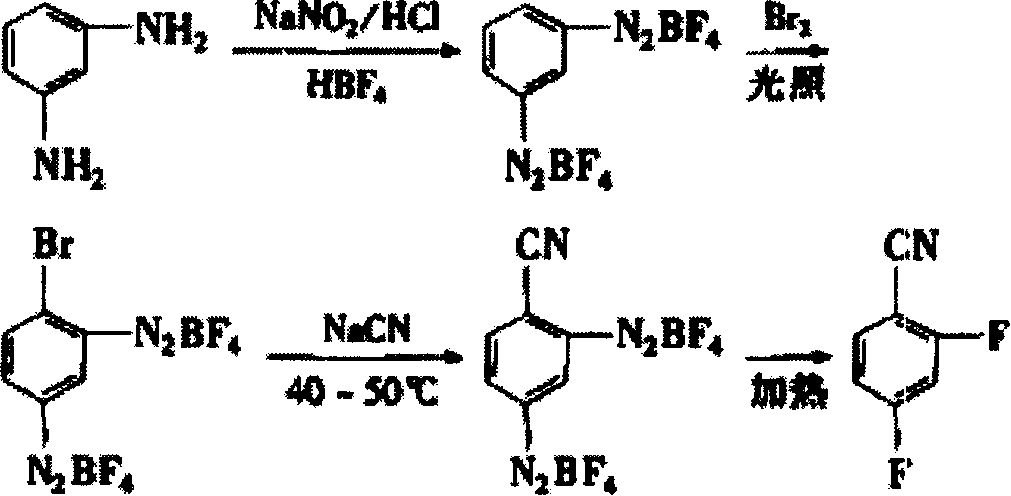

A difluorobenzonitrile and production process technology, applied in two fields, can solve the problems of long reaction process cycle time, complex catalyst preparation, complex post-treatment, etc., and achieve the effects of high yield, low pollution and short reaction process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] In a 1000 ml three-necked flask, under nitrogen protection, 500 ml of N,N-dimethylacetamide solvent, 57.6 g (300 mmol) of 2,4-difluorobromobenzene, 25 g (60 mmol, 0.2 Equivalent) potassium ferrocyanide trihydrate, 680 mg (3 mmol, 0.3 mol%) palladium acetate catalyst, 35 g of sodium carbonate (330 mmol, 1.1 equiv), under nitrogen protection at 100 ° C for 2 hours with stirring, The reaction was completed, followed by filtration, and the filtrate was fractionated under reduced pressure to obtain white crystals of 2,4-difluorobenzonitrile with a yield of 85%, a purity of 98%, a boiling point of 84-86°C (2666.4 Pa), and a melting point of 47-49°C.

Embodiment 2

[0027] In a 1000 ml three-necked flask, under nitrogen protection, 500 ml of N,N-dimethylacetamide solvent, 57.6 g (300 mmol) of 2,4-difluorobromobenzene, 28 g (66 mmol, 0.3 Equivalent) potassium ferrocyanide trihydrate, 340 mg (1.5 mmol, 0.5 mol%) of palladium acetate catalyst, 31.8 g of sodium carbonate (300 mmol, 1.0 equiv.), and the reaction was stirred at 120 ° C for 3 hours under nitrogen protection, The reaction was completed, followed by filtration, and the filtrate was fractionated under reduced pressure to obtain white crystals of 2,4-difluorobenzonitrile with a yield of 90%, a purity of 99%, and a melting point of 48-49°C.

Embodiment 3

[0029] In a 1000 ml three-necked flask, under nitrogen protection, 500 ml of N,N-dimethylacetamide solvent, 57.6 g (300 mmol) of 2,4-difluorobromobenzene, 27 g (66 mmol, 0.22 equiv) sodium ferrocyanide trihydrate, 15 mmol (5 mol %) bis(dibenzylidenepyruvate) palladium catalyst, 31.8 g sodium carbonate (300 mmol, 1.0 equiv), stirred at 120°C under nitrogen protection The reaction was completed for 1 hour, followed by filtration, and the filtrate was fractionated under reduced pressure to obtain 2,4-difluorobenzonitrile as white crystals with a yield of 87%, a purity of 98%, and a melting point of 47-49°C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com