Semiconductor encapsulating epoxy resin composition and semiconductor device

A technology of epoxy resin and semiconductor, which is applied in the direction of semiconductor devices, semiconductor/solid device components, electric solid devices, etc., can solve the problems of insulating film sealing resin cracks, low mechanical strength, peeling, etc., and achieve good warping characteristics, Excellent temperature cycle performance and excellent humidity resistance reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0078] [Preparation of epoxy resin composition, etc.]

[0079]As a general method for preparing the sealing resin composition of the present invention into a molding material, epoxy resin, curing agent, silicon dioxide, and other additives can be mixed in a prescribed composition ratio, and after being fully mixed with a mixer, etc., Melt and mix with hot rollers, kneaders, extruders, etc., then cool and solidify, crush to an appropriate size, and make molding materials. In addition, when the composition is fully mixed with a mixer or the like, it is preferable to make it wet by surface treatment with a silane coupling agent or the like in order to obtain better storage stability.

[0080] Here, examples of the silane coupling agent include γ-glycidoxypropyltrimethoxysilane, γ-glycidoxypropylmethyldiethoxysilane, γ-glycidoxypropyltriethoxysilane, and γ-glycidoxypropyltrimethoxysilane. Oxysilane, p-Styryltrimethoxysilane, γ-Methacryloxypropylmethyldimethoxysilane, γ-Methacrylo...

Embodiment 1~10

[0084] "Examples 1-10, Comparative Examples 1-6"

[0085] The components shown in Table 1 were melt-mixed until uniform using a hot twin-roller, cooled and pulverized to obtain an epoxy resin composition for semiconductor sealing. The raw materials used are as follows.

[0086] (epoxy resin)

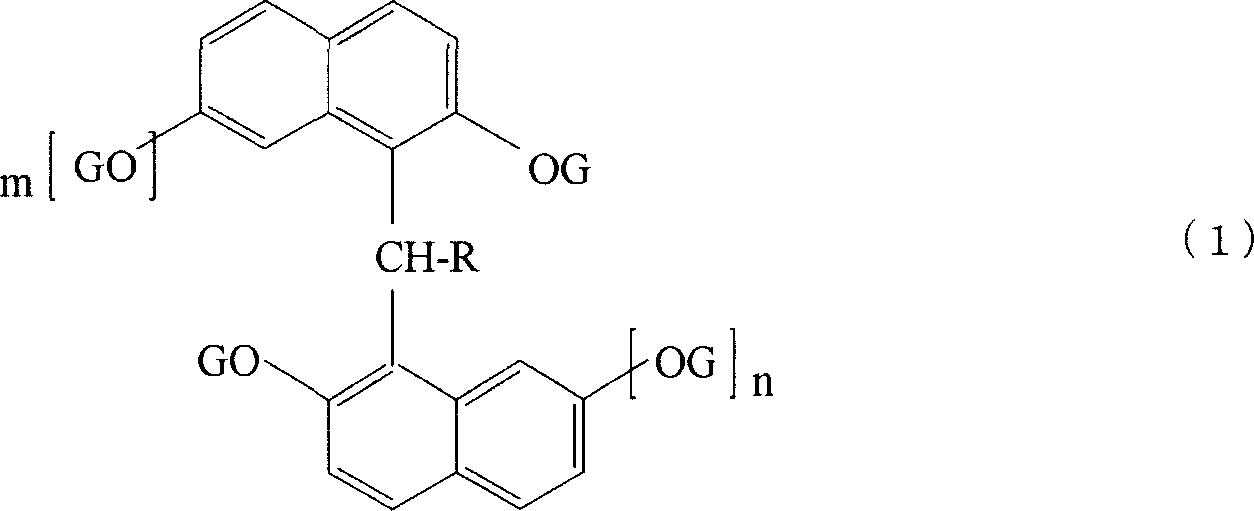

[0087] Among the epoxy resins of the above formula (1), for the epoxy resins (i) to (iii) of the following structures having different m and n values, epoxy resins (1) to (iii) as shown in Table 1 are used in accordance with their compounding ratios. (4) and (5) biphenyl arane epoxy resin (NC3000: manufactured by Nippon Kayaku Co., Ltd., brand name). G is the same as above.

[0088] Epoxy resin (i) (m=0, n=0)

[0089] [chemical formula 10]

[0090]

[0091] Epoxy resin (ii) (n=0 when m=1, n=1 when m=0)

[0092] [chemical formula 11]

[0093]

[0094] Epoxy resin (iii) (m=1, n=1)

[0095] [chemical formula 12]

[0096]

[0097] [Table 1]

[0098] Epoxy Resin ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com