Hydraulic sheeting and use method thereof

A hydraulic plug-in and skateboard technology, applied in sheet pile walls, water conservancy projects, marine engineering, etc., can solve the problems of prolonged construction time, slow pile entry, single, etc., and achieve the effect of improving construction speed and accelerating pile entry speed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

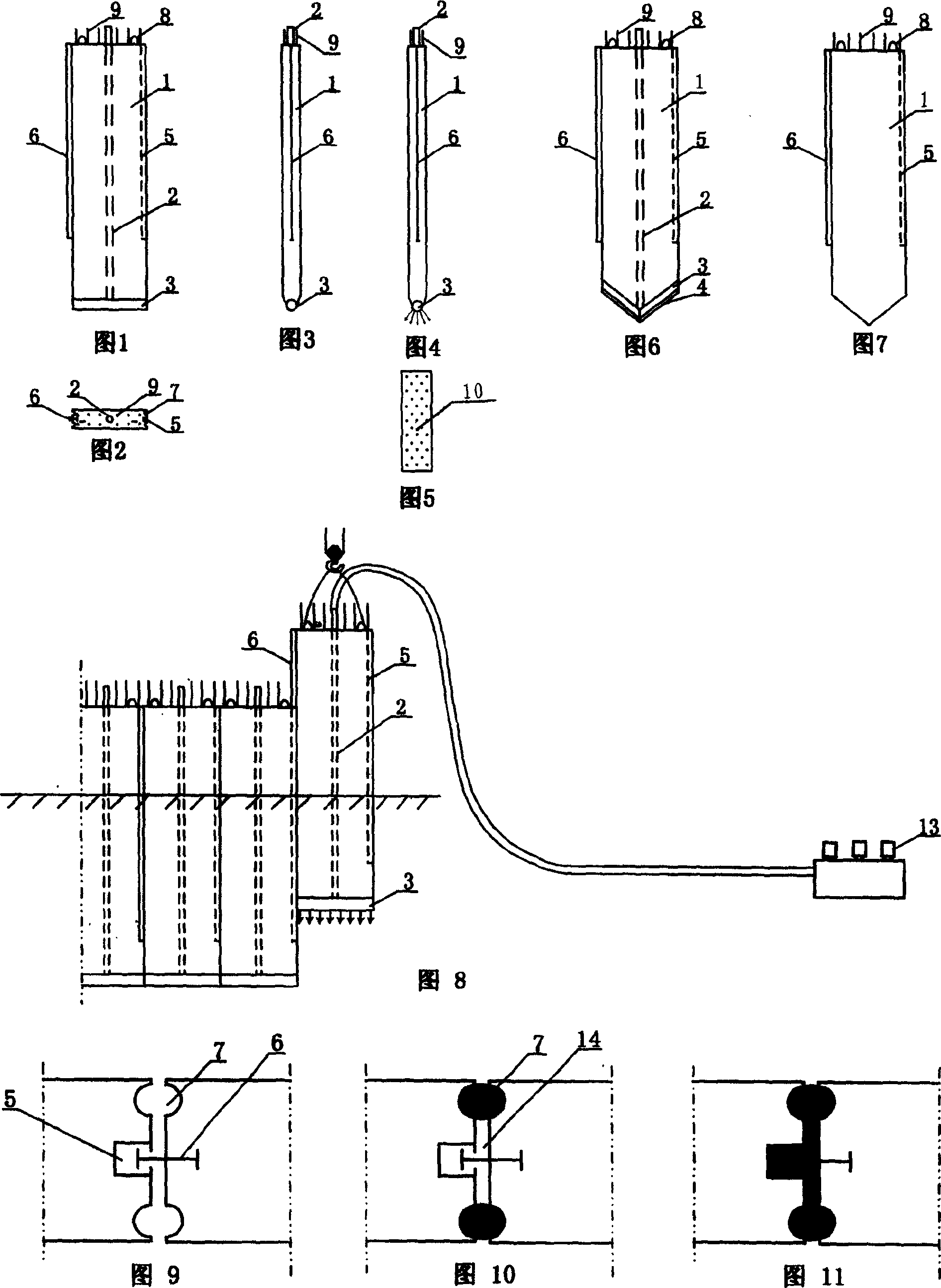

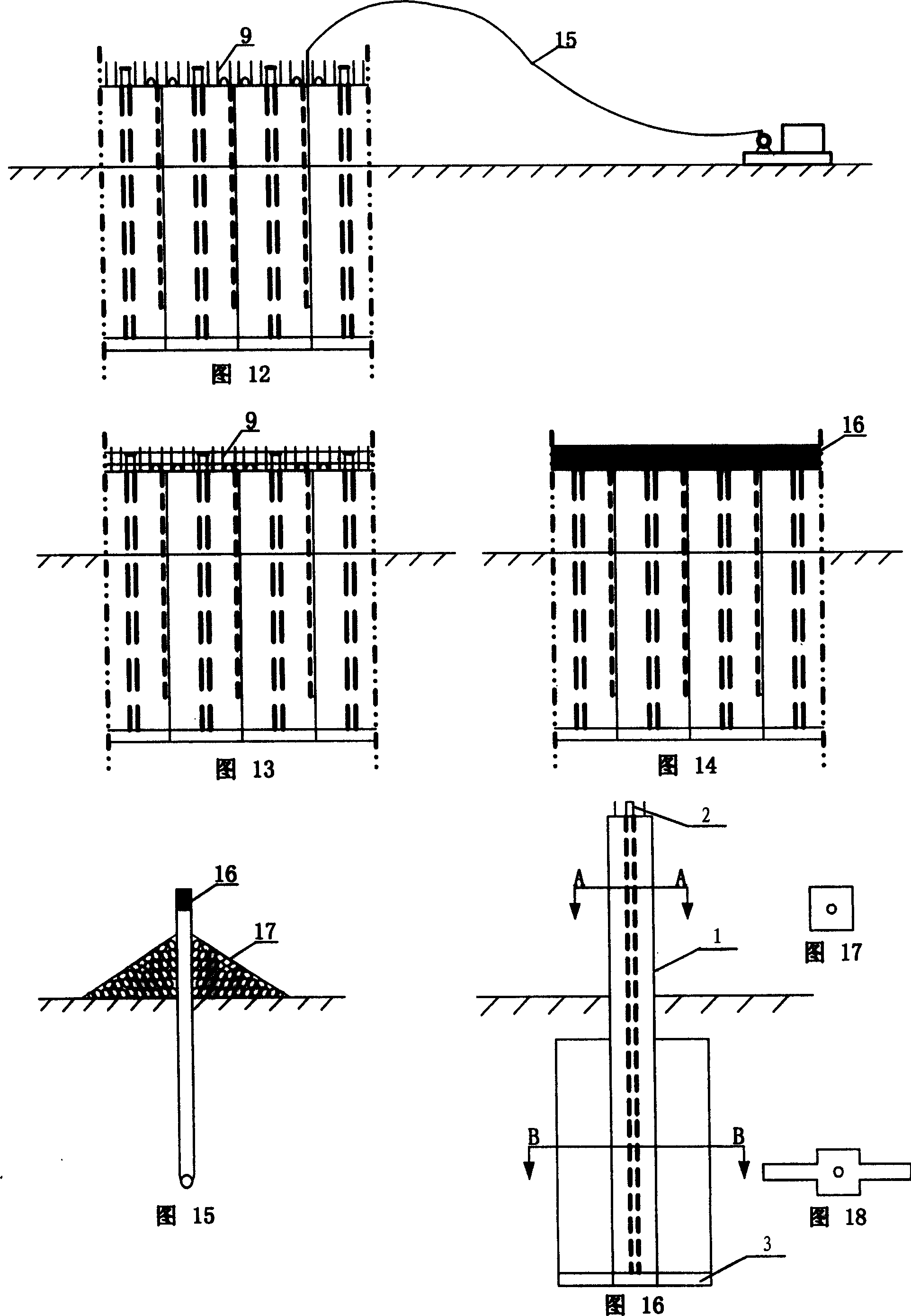

[0034] Refer to Fig. 1-Fig. 18, a kind of hydraulic inserting plate, including reinforced concrete pile slab 1 and the water passing pipe 2 vertically installed in it, the water distribution pipe 3 connected with the water passing pipe installed horizontally at the bottom, and installed on one side The slideway 5, the slideway 6 installed on the other side, the hoisting ring 8 installed on the top and the reserved steel bar 9 buried, also include the vertical set on the reinforced concrete pile slab 1, the slideway, and the two sides of the slideboard. To the aqueduct 7.

[0035] The lower end of the reinforced concrete pile slab 1 is parallel, conical or single-sided oblique. The upper part of the water distribution pipe 3 is embedded in the reinforced concrete pile slab, and the lower half is provided with water injection holes 10, the diameter of which is 2-8mm, and each injection hole is on the cross-section of the reinforced concrete pile slab. The distribution area is 9...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com