Indirect glomeration dispersedly fixed type nano titanium dioxide particle preparation method

A nano-titanium dioxide, nano-particle technology, applied in chemical instruments and methods, catalyst activation/preparation, catalyst protection and other directions, can solve the problems of reduced nano-particle activity, reduced particle catalytic activity, low efficiency of decomposing organic matter, etc., to expand the application field , the effect of protecting the environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

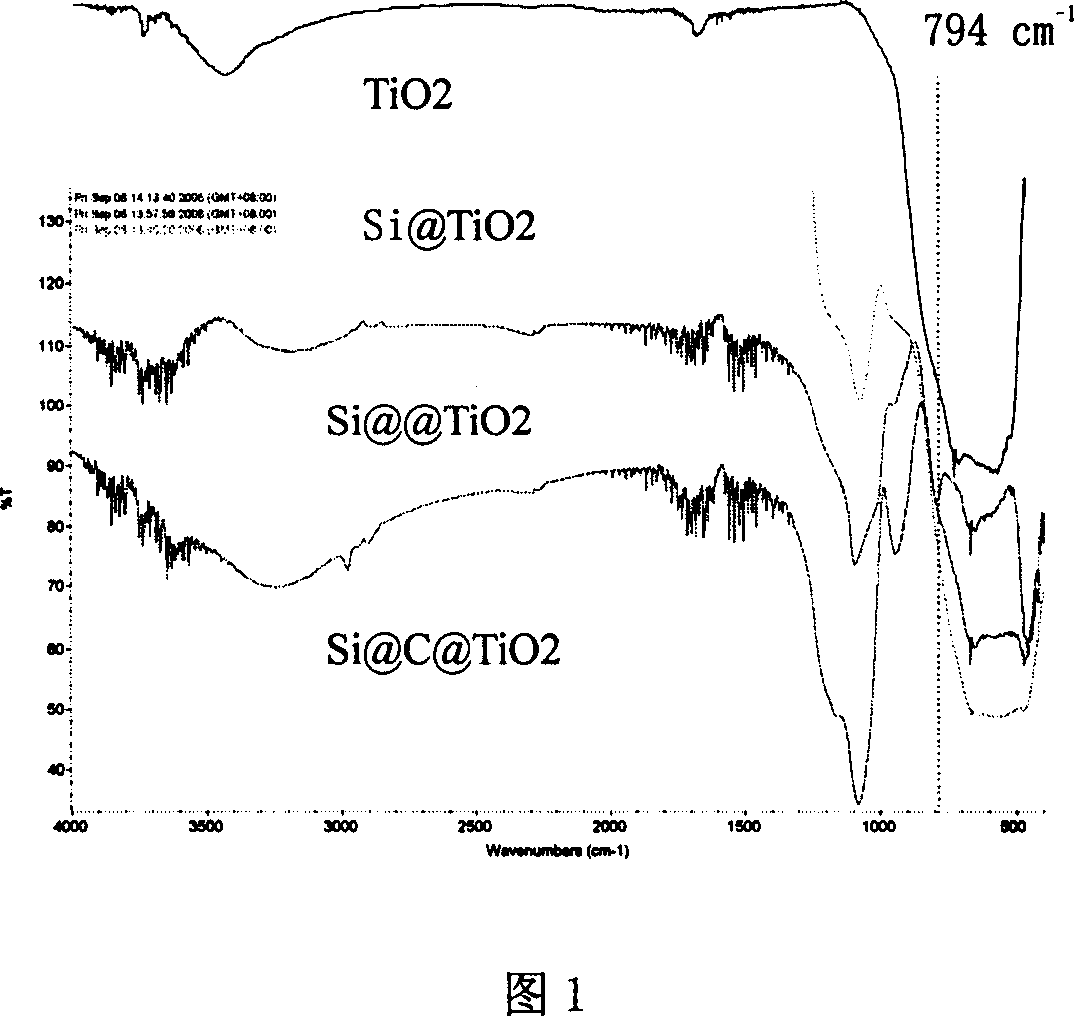

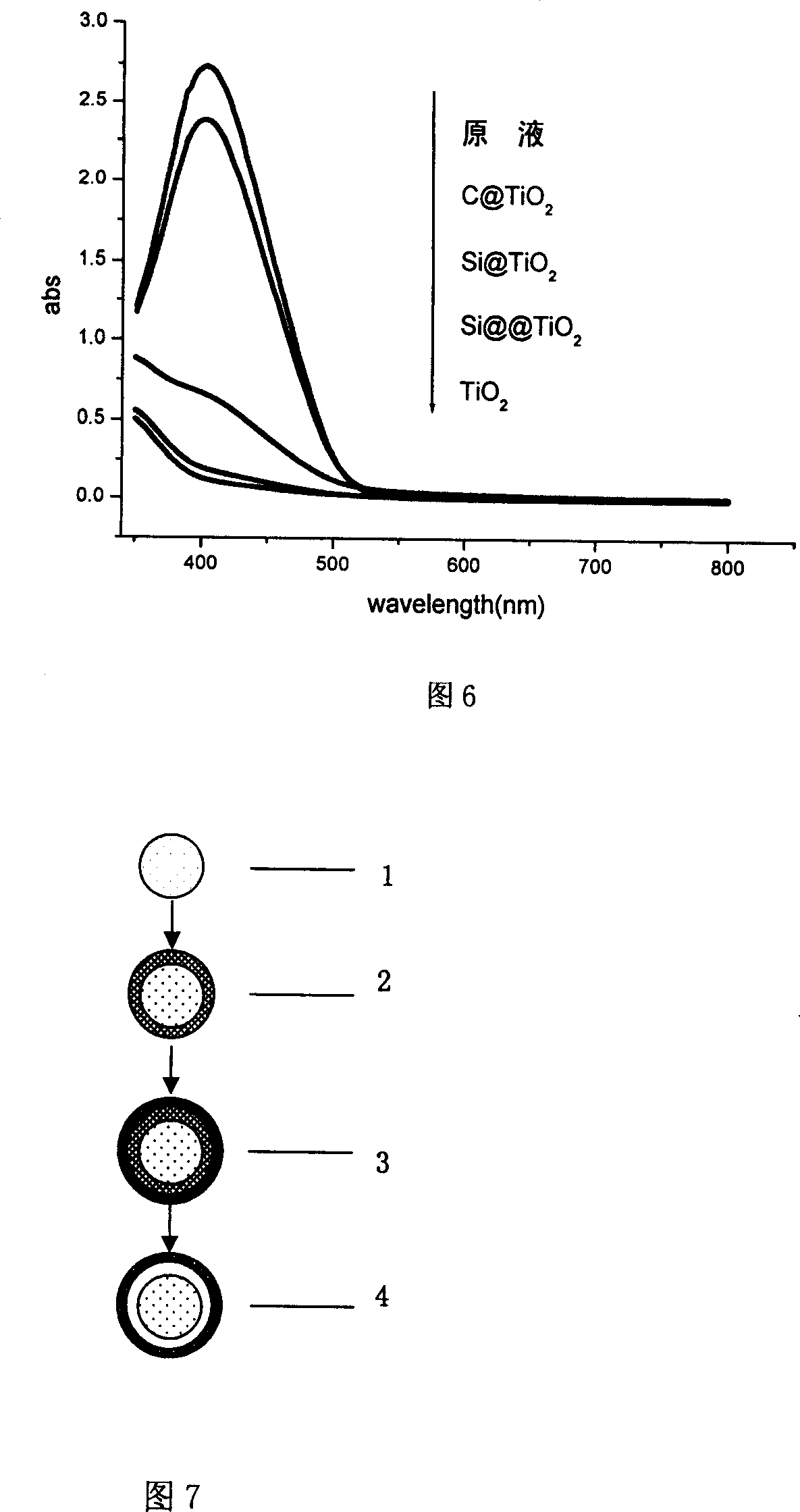

[0040] Embodiment 1, as shown in Figure 7:

[0041] (a) pretreatment of titanium dioxide nanoparticles,

[0042] Add 100 mg of titanium dioxide nanoparticles into a NaOH solution with a concentration of 0.5 mol / L, and magnetically stir at a speed of 500 rpm for 7 hours, then wash with water three times and centrifuge until the pH is 7 for use.

[0043] (b) carbon coated on the surface of nanoparticles,

[0044]Add 100 mg of nanoparticles prepared in step (a) into polyvinyl alcohol resin (PVA) in an aqueous solution of carbon-containing organic matter soluble in water at a concentration of 0.7 mol / L. After thorough mixing, the mixed solution was introduced into a hydrothermal reaction kettle, and heat-treated at 150° C. for 2 hours. After the reaction, it was washed three times with methanol, an organic solvent, and three times with distilled water, and then dried for use.

[0045] (c) the outer layer of carbon-coated nanoparticles coated with silica,

[0046] (1) Stir 100 ...

Embodiment 2

[0052] Embodiment 2, as shown in Figure 7:

[0053] (a) pretreatment of titanium dioxide nanoparticles,

[0054] Add 500 mg of titanium dioxide nanoparticles into the HCL solution with a concentration of 1.2 mol / L, and magnetically stir at 1000 rpm for 14 hours, then wash with water five times and centrifuge until the pH is 7 for use.

[0055] (b) carbon coated on the surface of nanoparticles,

[0056] Add 450 mg of nanoparticles prepared in step (a) into polyethylene glycol (PEG) in an aqueous solution of carbon-containing organic matter soluble in water at a concentration of 2.2 mol / L. After thorough mixing, the mixed solution was introduced into a hydrothermal reaction kettle, and heat-treated at 200° C. for 8 hours. After the reaction, wash with organic solvent ethanol for 7 times, wash with distilled water for 7 times, and then dry for use.

[0057] (c) the outer layer of carbon-coated nanoparticles coated with silica,

[0058] (1) Stir 450 mg of the sample obtained i...

Embodiment 3

[0064] Embodiment 3, as shown in Figure 7:

[0065] (a) pretreatment of titanium dioxide nanoparticles,

[0066] Add 300 mg of titanium dioxide nanoparticles into NaOH solution with a concentration of 0.8 mol / L, magnetically stir at 750 rpm for 10 hours, wash with water four times and centrifuge until the pH is 7 for use.

[0067] (b) carbon coated on the surface of nanoparticles,

[0068] Add 275 mg of nanoparticles prepared in step (a) into 1.4 mol / L aqueous solution of soluble carbon-containing organic matter sucrose (Sucrose). After thorough mixing, the mixed solution was introduced into a hydrothermal reaction kettle, and heat-treated at 175° C. for 5 hours. After the reaction, it was washed 5 times with the organic solvent acetone, and then 5 times with distilled water, and then dried for use.

[0069] (c) the outer layer of carbon-coated nanoparticles coated with silica,

[0070] (1) Stir 275 mg of the sample obtained in step (b), 10 ml of chloroform, 450 μl of ultr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com