Droplet ejection apparatus

A droplet ejection head, droplet technology, applied in printing, typewriter, etc., can solve the problems of evaporative component pollution, optical system pollution, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

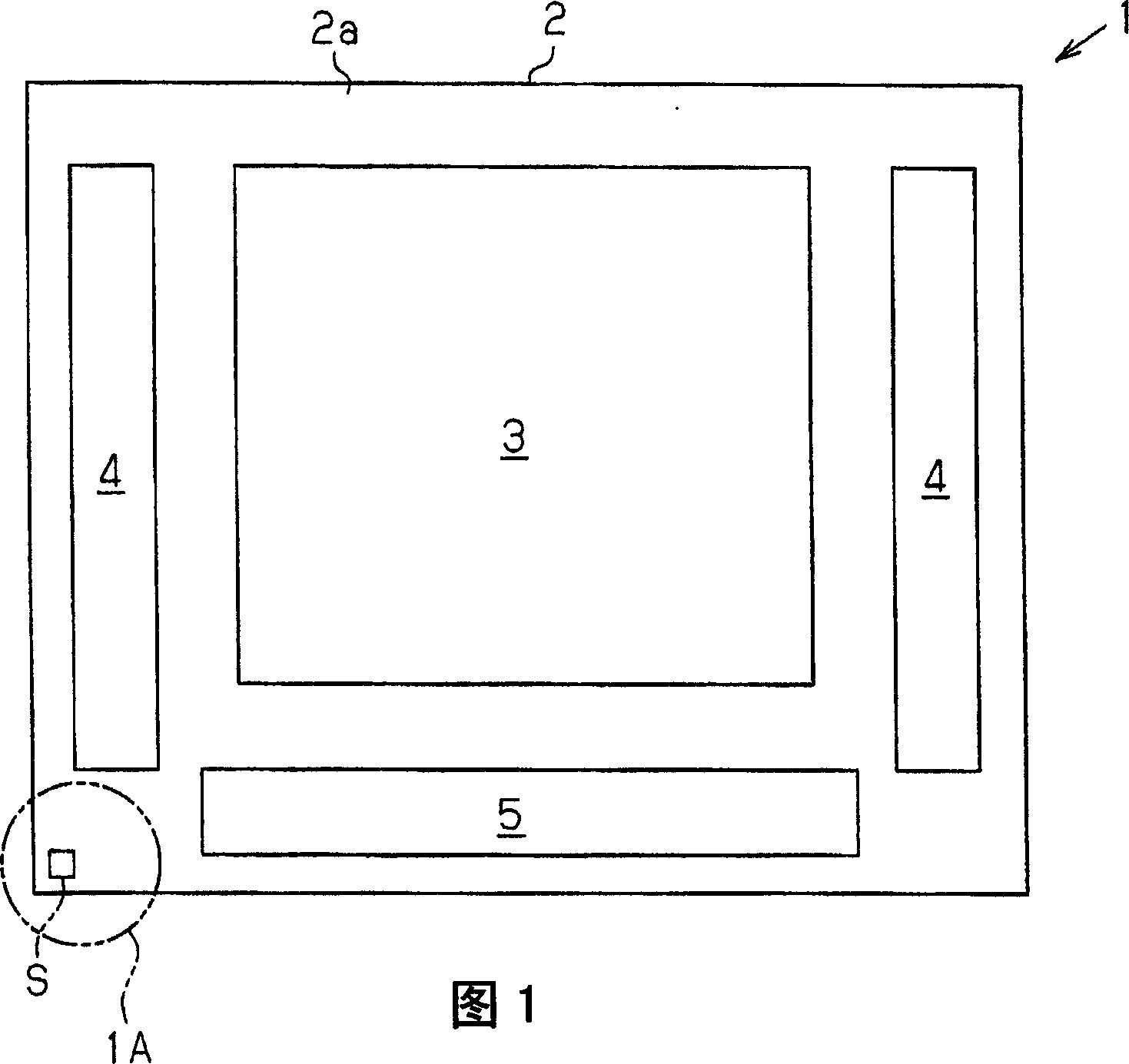

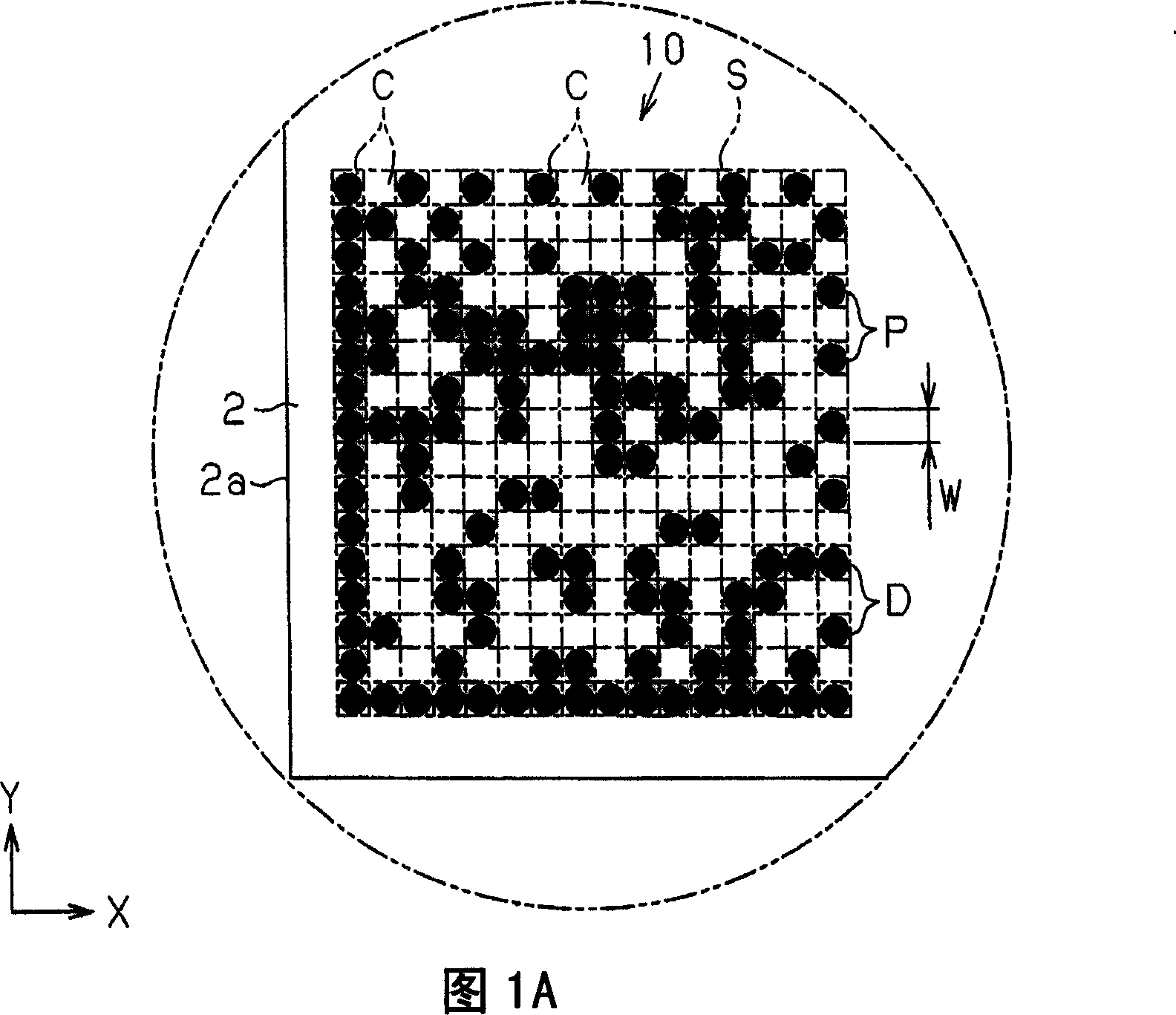

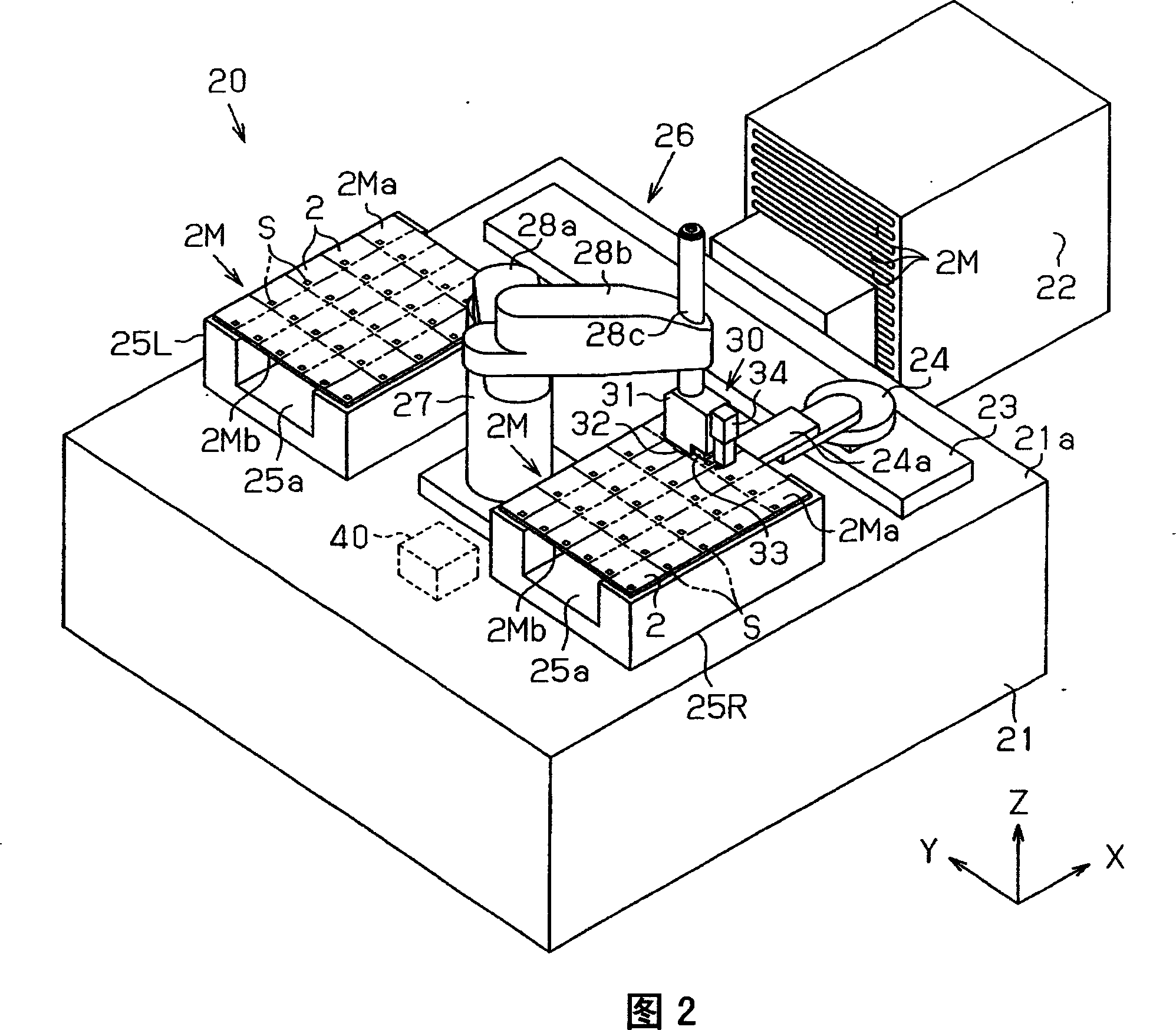

[0021] Hereinafter, an embodiment embodying the present invention will be described with reference to FIGS. 1 to 7 . First, the liquid crystal display device 1 having the identification code 10 formed using the droplet discharge device 20 of the present invention will be described.

[0022] In FIG. 1 , a quadrangular display portion 3 in which liquid crystal molecules are sealed is formed approximately at the center of one side surface (surface 2 a ) of a transparent substrate 2 . A scanning line driving circuit 4 and a data line driving circuit 5 are formed outside the display unit 3 . The liquid crystal display device 1 controls the alignment state of liquid crystal molecules in the display portion 3 based on the scanning signals generated by the scanning line driving circuit 4 and the data signals generated by the data line driving circuit 5 . The liquid crystal display device 1 displays a desired image in the region of the display unit 3 by modulating planar light from an...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap