Long-period optical fiber grating band-pass filtering method and band-pass filter for realizing the same method

A technology of fiber grating and band-pass filtering, which is applied in the field of long-period fiber grating band-pass filters, and achieves the effects of stable performance, easy batching, and high production yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be further elaborated below in conjunction with accompanying drawing:

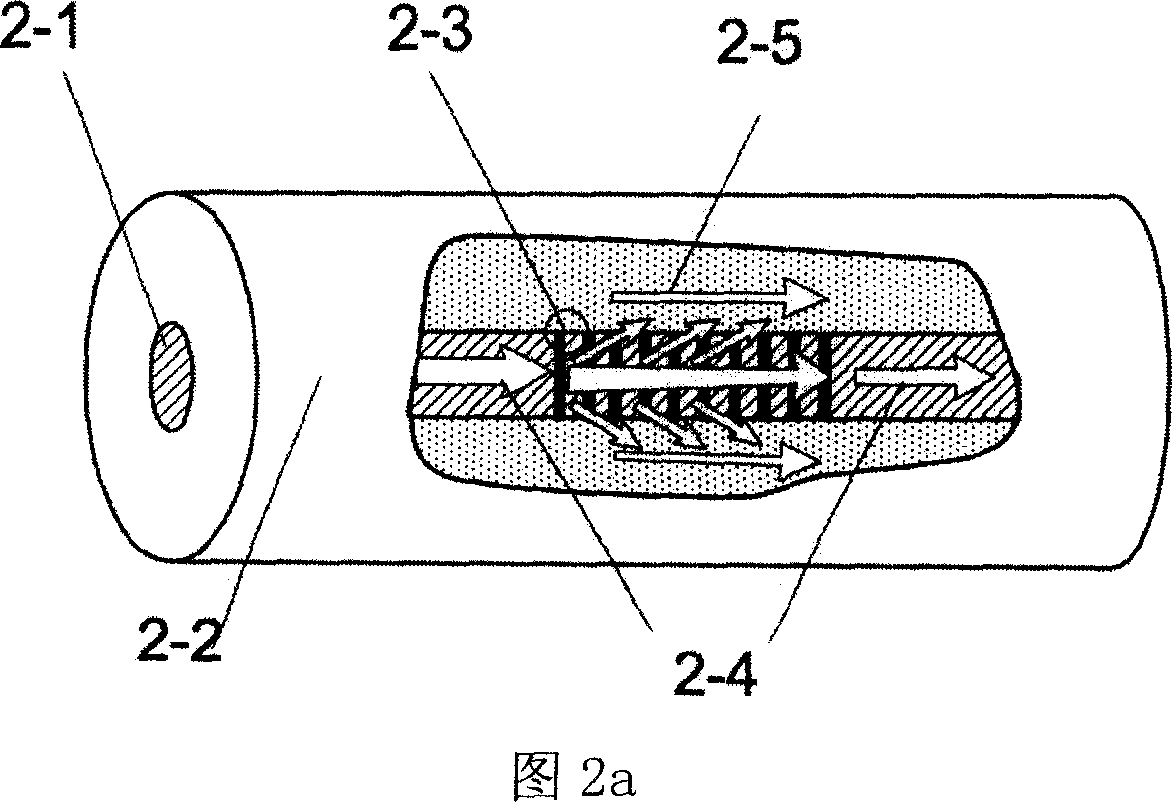

[0037] Referring to Figure 3a, the long-period fiber grating bandpass filter includes two fully matched and connected first long-period fiber gratings (abbreviated as LPFG-I) and second long-period fiber gratings (abbreviated as LPFG-II). The end of the fiber core 2-1 of the rear end face 2-6 of LPFG-I is made with a metal titanium tungsten coating as the core mode absorber 2-7, and the diameter of the core mode absorber 2-7 is 9 microns, and the fiber core 2- 1 with the same diameter. This long-period fiber grating bandpass filter is manufactured using micro-electromechanical systems (MEMS) and micro-nano manufacturing technology, see Figure 4, the process flow is as follows:

[0038] 1) Preprocessing:

[0039] Prepare a pair of matching long-period fiber gratings, take LPFG-I, and treat its rear end surface as a mirror surface;

[0040] 2) Cleaning:

[0041] Soak in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com