Catalyst for preparing cyclohexene by benzene selective hydrogenation, its preparing method and use

A catalyst and cyclohexene technology, applied in the direction of metal/metal oxide/metal hydroxide catalyst, physical/chemical process catalyst, hydrogenation hydrocarbon production, etc., can solve the problem of low benzene conversion activity and achieve high cyclohexene Selectivity, effect of high benzene conversion activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

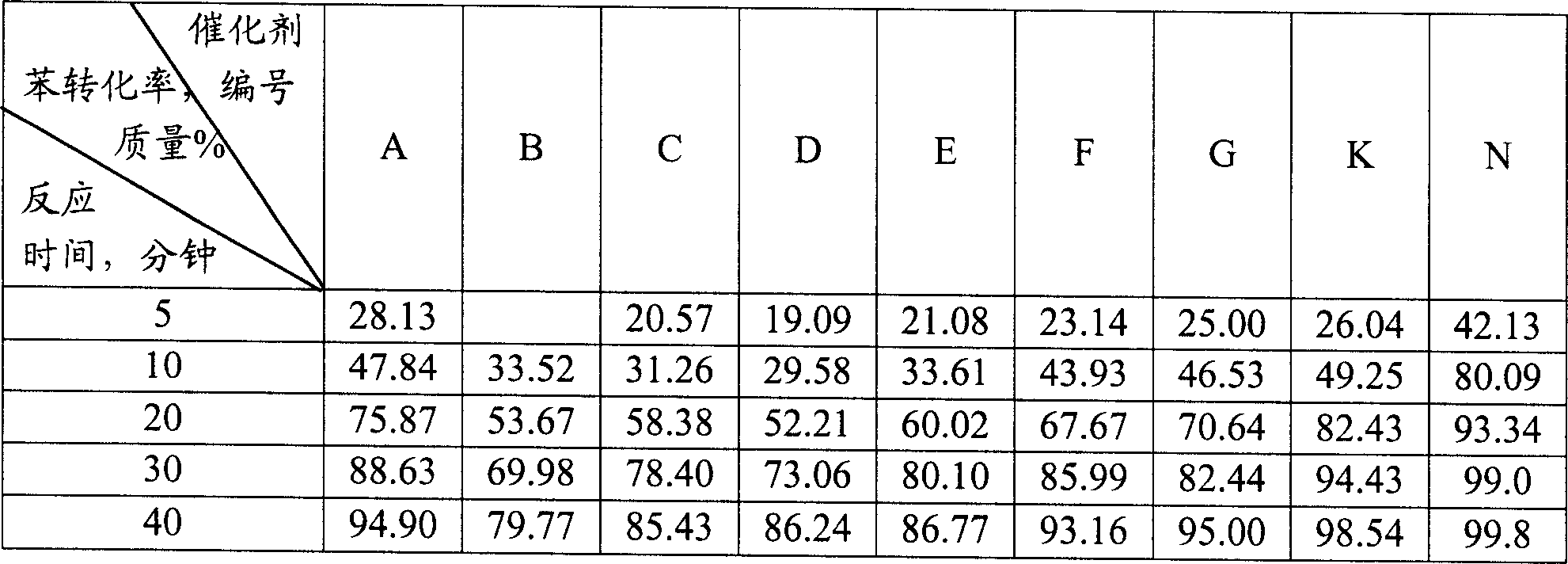

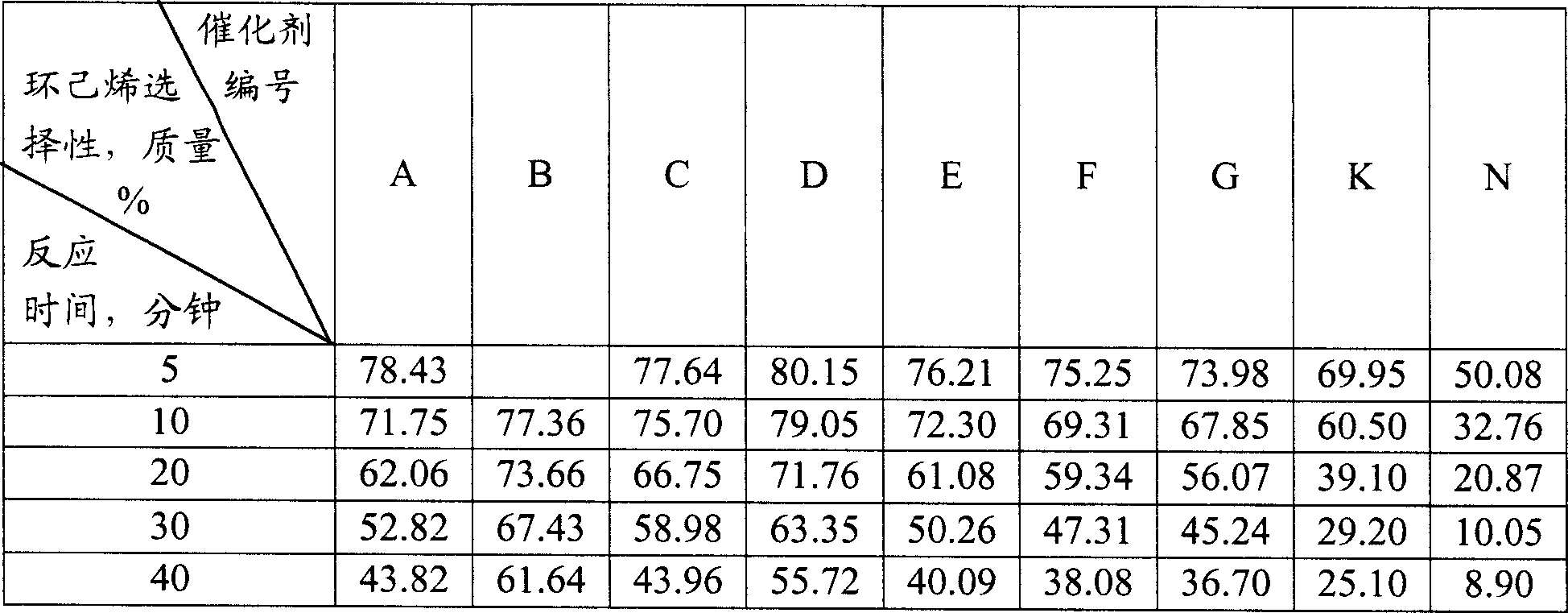

Examples

preparation example Construction

[0015] The preparation method of the catalyst provided by the invention comprises mixing soluble compound solutions containing Ru and M, and then mixing with zirconia containing yttrium oxide, adding an alkaline aqueous solution of sodium borohydride under stirring to fully react, and isolating a solid product, Washing with deionized water until the solution is neutral, washing with ethanol, and then drying, the M is selected from Co, Fe, Ni or Cu.

[0016] Catalyst of the present invention adopts chemical reducing agent to prepare, and reducing agent is preferably NaBH 4 . Y 2 o 3 Mix the mixed solution of zirconia containing ruthenium and the water-soluble compound containing additive M, stir for 1 to 5 hours to disperse the solid evenly, and then add NaBH dropwise to it 4 The alkaline aqueous solution fully reacts, the active components and additives are reduced to a metal state, and the stirring is stopped. Stand still at 20-30°C for 4-12 hours, use centrifugation to s...

example 1

[0024] Preparation of the catalyst of the present invention.

[0025] (1) Preparation containing Y 2 o 3 of zirconia.

[0026] Dissolve 50 g of zirconium oxychloride and 1.37 g of yttrium nitrate in 1000 ml of deionized water, raise the temperature to 80° C. and stir for 2 hours, and quickly add 100 ml of NaOH solution with a concentration of 25% by mass to react for 4 hours. The stirring was stopped, and the resultant was aged at 25° C. for 24 hours. Filter, wash the solid with absolute ethanol 3 times, dry under reduced pressure at 35°C for 12 hours, and roast at 500°C for 4 hours to obtain a powder containing 5.0 mass% Y 2 o 3 ZrO 2 carrier.

[0027] (2) Preparation of catalyst

[0028] Take 20 grams containing 5.0 mass% Y 2 o 3 The zirconia support was put into a beaker, and 7.03 g of RuCl 3 ·3H 2 O (purity 99.99%, ruthenium content 37±0.4%), 0.73 g CoCl 2 ·6H 2 O mixed with 47 ml of deionized water was added to the beaker and stirred for 1 hour. Add 3.91 g o...

example 2

[0030] Containing 5.0% by mass Y 2 o 3 20 grams of zirconia powder, prepare catalyst B by the method of example 1 (2), except that 7.03 grams of RuCl 3 ·3H 2 O, 0.64 g FeCl 2 4H 2O and 80 ml of deionized water were mixed and added to the beaker, stirred for 1 hour, and then added dropwise by 3.92 g of NaBH 4 , 0.8 gram of NaOH and 40 milliliters of deionized water were reduced, and the solid obtained was washed with water and alcohol, and dried to obtain catalyst B, whose composition is shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com