Method for preparing high-purity phosphotungsticacid

A technology of pure phosphotungstic acid and phosphotungstic acid, applied in chemical instruments and methods, tungsten compounds, inorganic chemistry, etc., can solve the problems of large amount of organic solvent, complicated preparation process, and reduce the safety of large-scale industrial production. The effect of reduced corrosion, simple process and improved safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

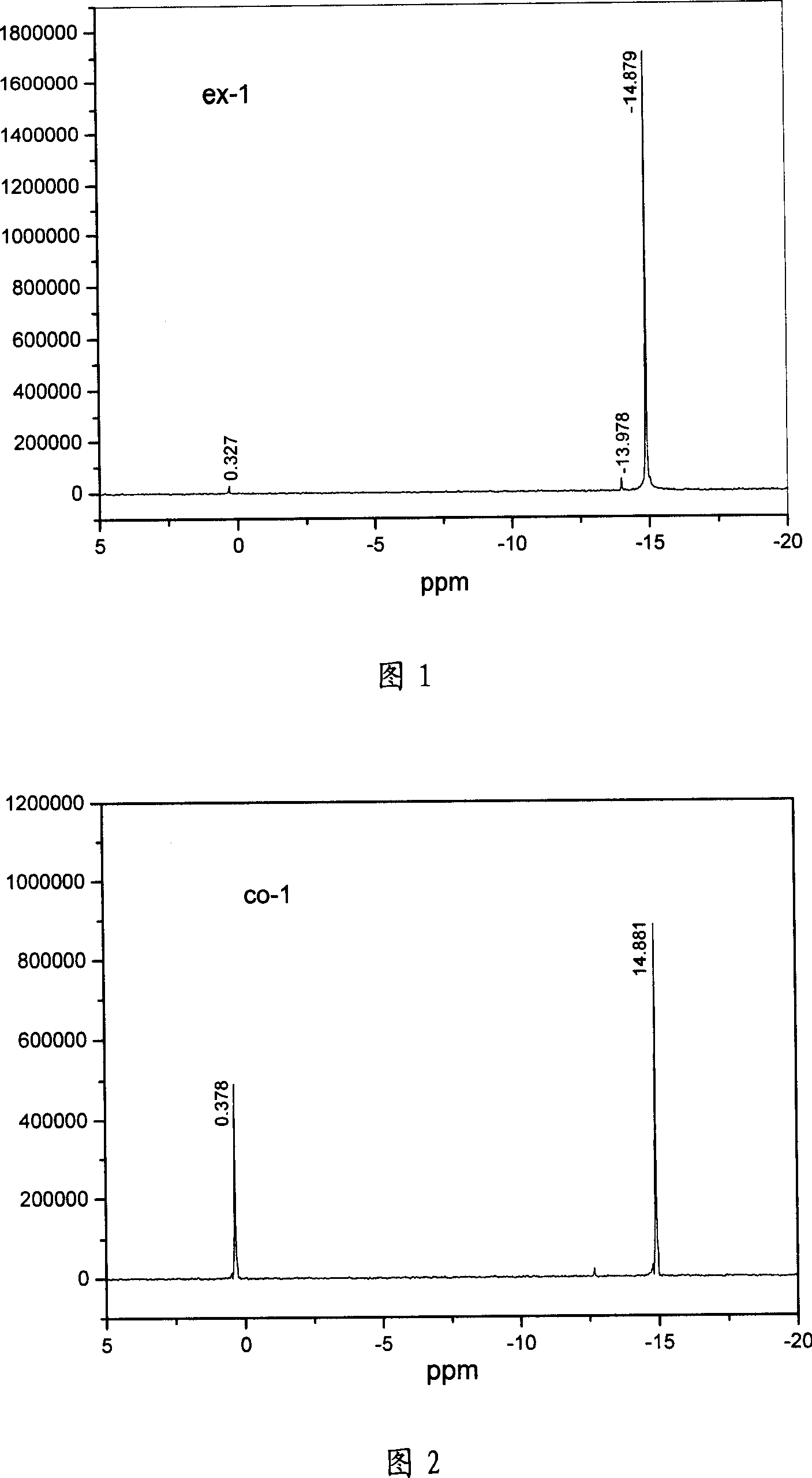

Embodiment 1

[0037] Weigh 50 grams of sodium tungstate to make 1000ml of sodium tungstate aqueous solution with a concentration of 0.15mol / L; weigh 50 grams of concentrated hydrochloric acid to make 600ml of hydrochloric acid solution with a concentration of 0.8mol / L (H + with WO 4 2- The molar ratio is 3.2), pour this hydrochloric acid solution into a glass beaker, add the prepared sodium tungstate solution dropwise into the beaker at 15°C, let stand after the dropwise addition, filter, and wash to obtain active tungstic acid precipitate.

[0038] Add 38.5 g of the obtained active tungstic acid precipitate into 1000 ml of 0.06 mol / L phosphoric acid aqueous solution, raise the temperature to 55°C, and obtain a clear and transparent phosphotungstic acid solution. Adding 150 grams of 36% hydrochloric acid (molar concentration is 1.3 mol / L) to this solution at 12° C. generates a white precipitate, which is filtered and crystallized to obtain 33.20 grams of high-purity white phosphotungstic a...

Embodiment 2

[0040] Take by weighing 50 grams of sodium tungstate, make it into 1875ml of sodium tungstate aqueous solution with a concentration of 0.08mol / L; take 25 grams of concentrated hydrochloric acid, make it into 560ml of hydrochloric acid solution with a concentration of 0.4mol / L + with WO 4 2- The molar ratio is 1.5), pour this hydrochloric acid solution into a glass beaker, add the prepared sodium tungstate solution dropwise into the beaker at 45°C, and add 4.0 grams of aging agent aluminum chloride (molar concentration: 0.01mol / L), filter after aging for 0.5 hours, and wash.

[0041] Add 41.5 g of the obtained active tungstic acid precipitate into 1000 ml of 0.06 mol / L phosphoric acid aqueous solution, and fully stir at room temperature for 2 hours to obtain a clear and transparent phosphotungstic acid solution. Add 25 grams of hydrochloric acid (molar concentration is 0.24mol / L) that weight concentration is 36% to this solution at 74 ℃, generate white precipitate, filter, cr...

Embodiment 3

[0045] Take by weighing 50 grams of sodium tungstate, be made into concentration and be 150ml of sodium tungstate aqueous solution of 1.0mol / l; Take by weighing 100 grams of concentrated nitric acid (H + with WO 4 2- Molar ratio is 6.7), is made into the nitric acid solution 400ml that concentration is 2.5mol / l. Add the prepared nitric acid solution dropwise to the sodium tungstate solution at 8°C, then add 10 grams of aluminum nitrate (molar concentration: 0.049 mol / L), age for 8 hours, filter and wash. Add 39.2 grams of the obtained active tungstic acid precipitate into 100ml of 3.0mol / L phosphoric acid aqueous solution, stir well at room temperature, then raise the temperature to 80°C to obtain a clear and transparent phosphotungstic acid solution; add 100g of phosphotungstic acid to the solution at 50°C Weight concentration is 85% sulfuric acid (molar concentration is 5mol / L), generates white precipitate, filters, and crystallizes, promptly obtains the white phosphotungs...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com