Method for preparing phosphotungstic acid using ammonium paratungstate as raw material

A technology of ammonium paratungstate and phosphotungstic acid, applied in chemical instruments and methods, tungsten compounds, phosphorus oxyacids, etc., to achieve high yield, suitable for large-scale industrial production, and reduce production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

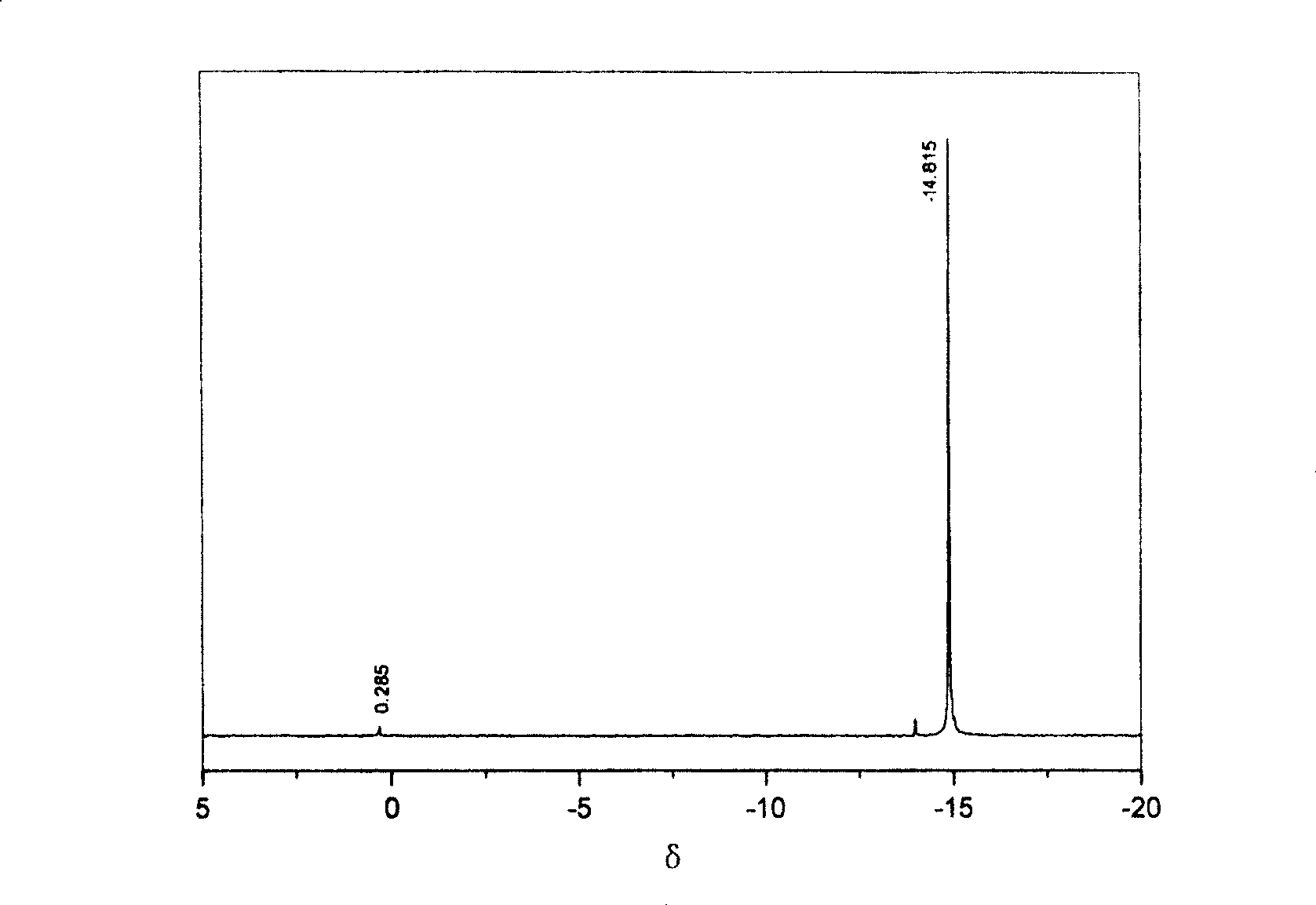

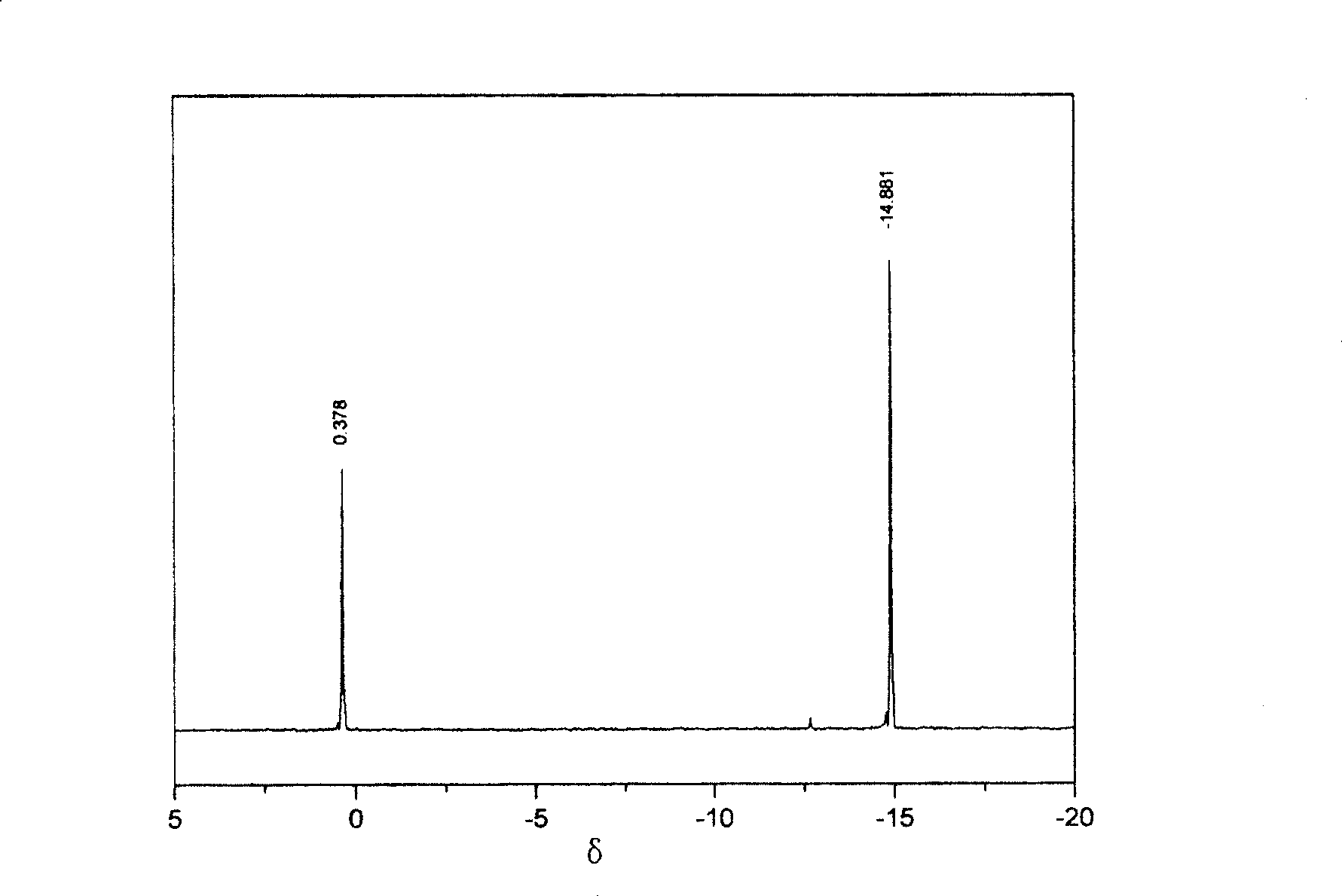

Image

Examples

Embodiment 1

[0037] Weigh 50 grams of concentrated hydrochloric acid and prepare 600 mL of hydrochloric acid solution with a concentration of 0.8 mol / L. Pour the hydrochloric acid solution into a glass beaker, and add 20 grams of ammonium paratungstate powder into the beaker at 15°C (the molar ratio of hydrochloric acid to ammonium paratungstate is 75 : 1), after stirring for 2.0 hours, an active tungstic acid precipitate was generated, left to stand, filtered, and washed.

[0038] Add 18.5 g of the obtained active tungstic acid precipitate into 100 mL of 2.0 mol / L phosphoric acid aqueous solution (the molar ratio of phosphoric acid to ammonium paratungstate is 31:1), raise the temperature to 60°C, and keep the temperature constant for 2 hours to obtain a clear and transparent phosphotungstic acid solution. Evaporate, concentrate, dry, crystallize to obtain 16.24 grams of high-purity white phosphotungstic acid. 3 PW 12 o 40 29H 2 O meter, yield is 74.8%.

Embodiment 2

[0040] Weigh 50 grams of concentrated hydrochloric acid and prepare 600 mL of hydrochloric acid solution with a concentration of 0.8mol / L. Pour the hydrochloric acid solution into a glass beaker, and add 20 grams of ammonium paratungstate powder into the beaker at 5°C (the molar ratio of hydrochloric acid to ammonium paratungstate is 75 : 1), stirring and reacting for 3.0 hours to generate active tungstic acid precipitation, then add 1.0 gram of aging agent aluminum chloride (molar concentration is 0.01mol / L), filter after aging for 2 hours, wash and leave standstill, filter, wash.

[0041] Add 19.8 g of the obtained active tungstic acid precipitate into 500 mL of 0.06 mol / L phosphoric acid aqueous solution (the molar ratio of phosphoric acid to ammonium paratungstate is 5:1), raise the temperature to 55°C, and keep the temperature for 2 hours to obtain a clear and transparent phosphotungstic acid solution. Evaporate, concentrate, dry, and crystallize to obtain 16.55 grams of h...

Embodiment 3

[0043] Weigh 50 grams of concentrated hydrochloric acid and prepare 600 mL of hydrochloric acid solution with a concentration of 0.8 mol / L. Pour the hydrochloric acid solution into a glass beaker, and add 20 grams of ammonium paratungstate powder into the beaker at 15°C (the molar ratio of hydrochloric acid to ammonium paratungstate is 75 : 1), stirred and reacted for 1.5 hours to generate active tungstic acid precipitates, left standstill, filtered, and washed.

[0044] Add 18.8 g of the obtained active tungstic acid precipitate into 500 mL of 0.06 mol / L phosphoric acid aqueous solution (the molar ratio of phosphoric acid to ammonium paratungstate is 5:1), raise the temperature to 55°C, and keep the temperature for 2 hours to obtain a clear and transparent phosphotungstic acid solution. Add 10 grams of hydrochloric acid (molar concentration is 0.2mol / L) with a weight concentration of 36% to this solution at 55°C to form a white precipitate, filter, dry, and crystallize to obta...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com