Electronic ink microcapsule, and its preparing method

An electronic ink and microcapsule technology, applied in microcapsule preparation, microsphere preparation, ink and other directions, can solve the problems affecting the molecular weight, time, temperature, pH value control of low molecular weight urea formaldehyde prepolymer, and the price of system regulators. Expensive and other problems, to achieve the effect of low price, tight capsule wall, and reduced control difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

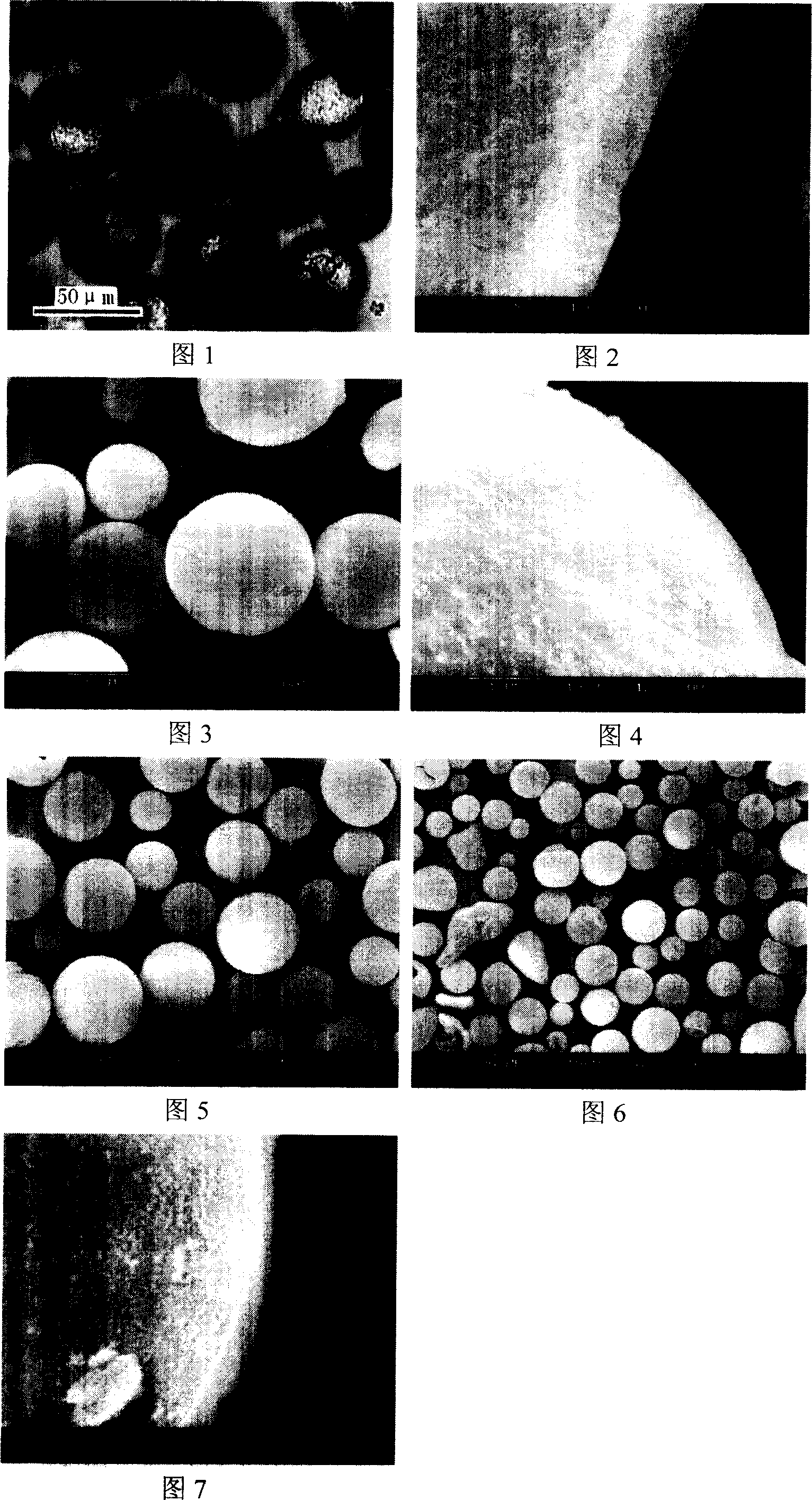

[0023] Carbon black with a particle size of 10-100nm is mixed with organically modified titanium dioxide whose surface has been modified by SDBS. The mass ratio of titanium dioxide is 1: 10), then add 25mg CH-6 hyperdispersant (produced by Shanghai Sanzheng Polymer Material Co., Ltd.), and disperse in 30mL tetrachlorethylene with the help of an ultrasonic breaker to obtain an electrophoretic display liquid. The mass content of the electrophoretic particles is 0.5%. Under stirring, control the temperature to 90°C, dissolve 0.3g of gelatin into 100mL of deionized water, cool to room temperature, obtain a gelatin solution with a mass concentration of 0.3% as the water phase, and dissolve 1.67g of urea (0.1 g / ml capsule core) and 0.167g resorcinol, after being dissolved, adjust the pH value to 1.5 with hydrochloric acid. Adjust the stirring speed to 1000 rpm, add 16.7mL of electrophoretic display solution, after the temperature rises to 60°C, add 3.8mL of 37% formaldehyde, the mo...

Embodiment 2

[0025] The difference between preparing the electrophoretic display solution and Example 1 is that the mass ratio of carbon black and modified titanium dioxide is 1:30, and the other conditions are the same as Example 1.

[0026] Adopt the same steps of Example 1 to prepare microcapsules, and the difference with the conditions of Example 1: the gelatin mass concentration is 0.1%, the urea consumption is 0.27 g / ml capsule core, the pH value is adjusted to 2.0, and the stirring speed is adjusted to 700 rpm. points; obtain electronic ink microcapsules containing two kinds of black and white inorganic particles, the scanning electron microscope (SEM) photo of the electronic ink microcapsules is shown in Figure 3, as can be seen from the SEM photo of Figure 3, the particle size of the microcapsules is 30 to 70 microns , The scanning electron microscope (SEM) photo of a single damaged electronic ink microcapsule is shown in Figure 4. From Figure 4, it can be seen that the thickness o...

Embodiment 3

[0028] The difference between preparing the electrophoretic display solution and Example 1 is that the mass ratio of carbon black and modified titanium dioxide is 1:20, and the other conditions are the same as Example 1.

[0029] The same steps as in Example 1 are used to prepare microcapsules, and the conditions are different from Example 1: the gelatin mass concentration is 1%, the urea consumption is 0.27 g / ml capsule core, the pH value is adjusted to 3.0, and the stirring speed is adjusted to 500 rpm. The electronic ink microcapsules containing black and white inorganic particles were obtained. The scanning electron microscope (SEM) photo of the electronic ink microcapsules is shown in Figure 5. It can be seen from Figure 5 that the particle size of the microcapsules is 40-110 microns. The SEM photos of the damaged microcapsules show that the thickness of the microcapsule wall is 2-5 microns.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com