Electrochemical method for detecting anodic oxidation aluminium formwork effective hole density

An anodized aluminum, electrochemical technology, applied in the direction of material electrochemical variables, measuring devices, scientific instruments, etc., can solve problems such as failure, inability to function, blind holes cannot be excluded, and achieve the effect of simple method and good reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

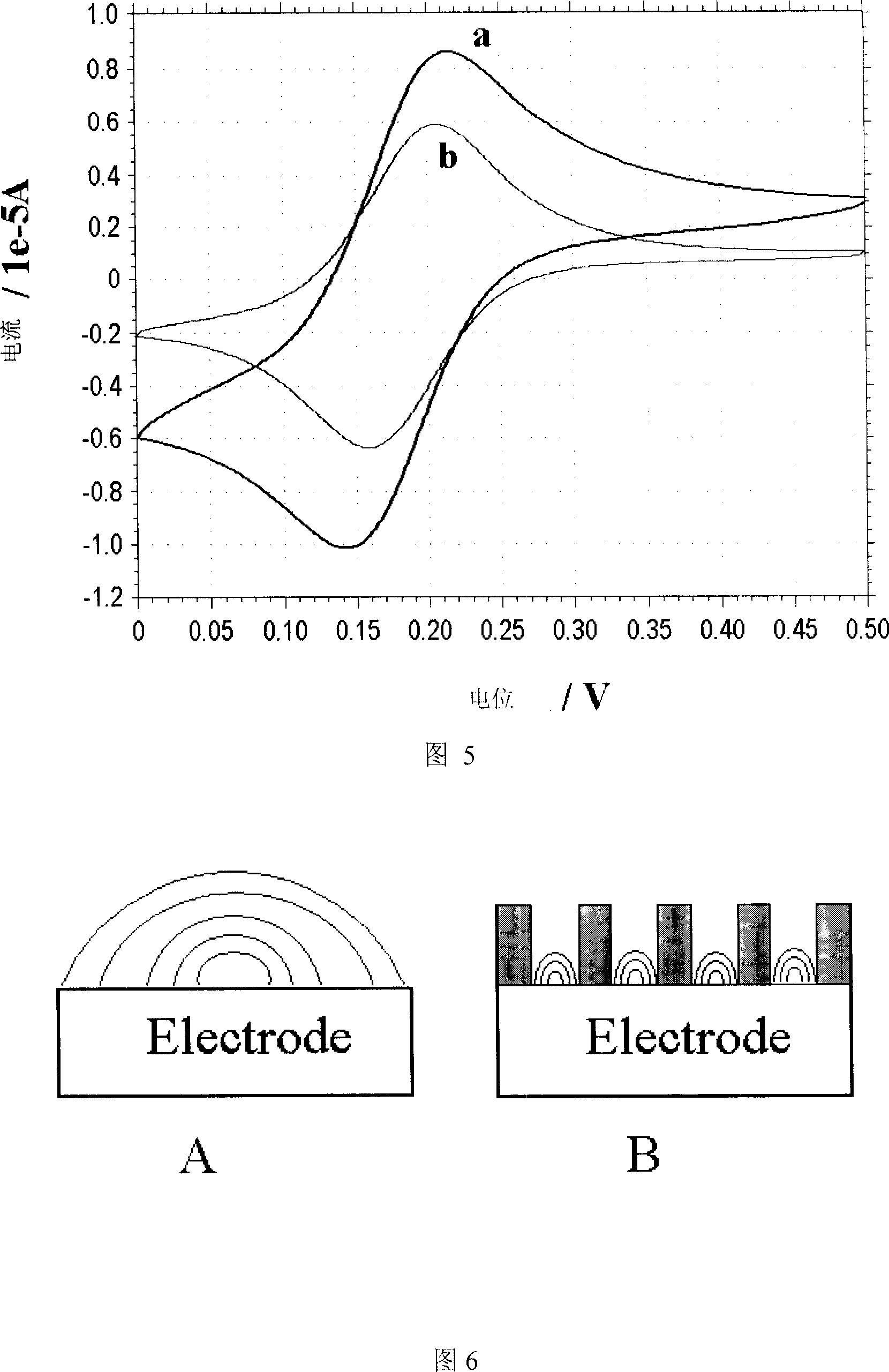

Embodiment 1

[0015] Embodiment 1: adopt three-electrode system, working electrode is the platinum electrode that self-made AAO template is arranged on the surface of working electrode is metal platinum disc electrode, and reference electrode is saturated calomel electrode (SCE), and counter electrode is platinum wire, and solution is 5mM K 3 Fe(CN) 6 , which contains 0.5M KCl supporting electrolyte. The cyclic voltammogram of the bare electrode (a) after the template exists on the electrode surface (b) is shown in Figure 5, the peak potential decreases from 65mV to 45mV, and the peak current decreases from 1.080×10 -5 A is reduced to 6.718×10 -6 a. Figure 7 is the SEM image of the self-made AAO template. The pore diameter is about 70nm. According to the ratio of the peak current before and after the template exists on the electrode surface and the value of the pore diameter, the pore density of the self-made AAO template can be calculated as 1.61×10 10 piece / cm 2 . This value is in th...

Embodiment 2

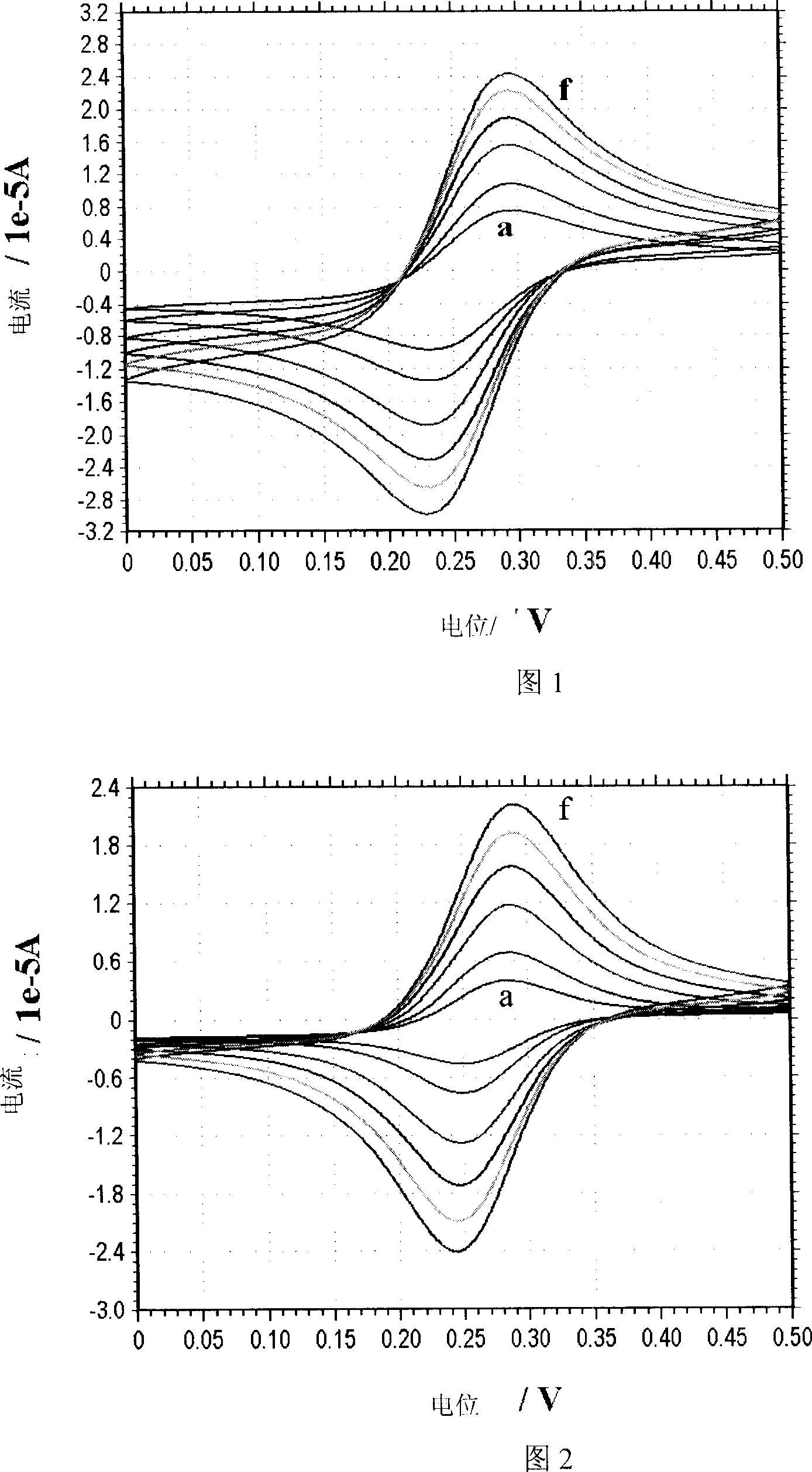

[0024] Embodiment 2: A three-electrode system is adopted, the working electrode is a metal platinum disk electrode and a platinum electrode with an AAO template on the surface, the reference electrode is an Ag / AgCl electrode, the counter electrode is a platinum wire, and the solution is 5mM K 3 Fe(CN) 6 , which contains 0.5M Na 2 SO 4 Supports electrolytes. at 5mM K 3 Fe(CN) 6 In the solution, at 10mV / s, 20mV / s, 40mV / s, 60mV / s, 80mV / s, 100mV / s, scan in the potential range from 0 to +0.5V, and record the cyclic voltammogram respectively (Figure 1), The redox peak spacing is about 60mV. When there is a template on the electrode surface, K 3 Fe(CN) 6 The reaction on the electrode is carried out through the pores of AAO, showing a controlled diffusion behavior, and the redox peak distance is about 40mV (Figure 2). At the same time, the peak current decreases, and the peak current still increases with the increase of the scan rate. , and the square root of the peak current ...

Embodiment 3

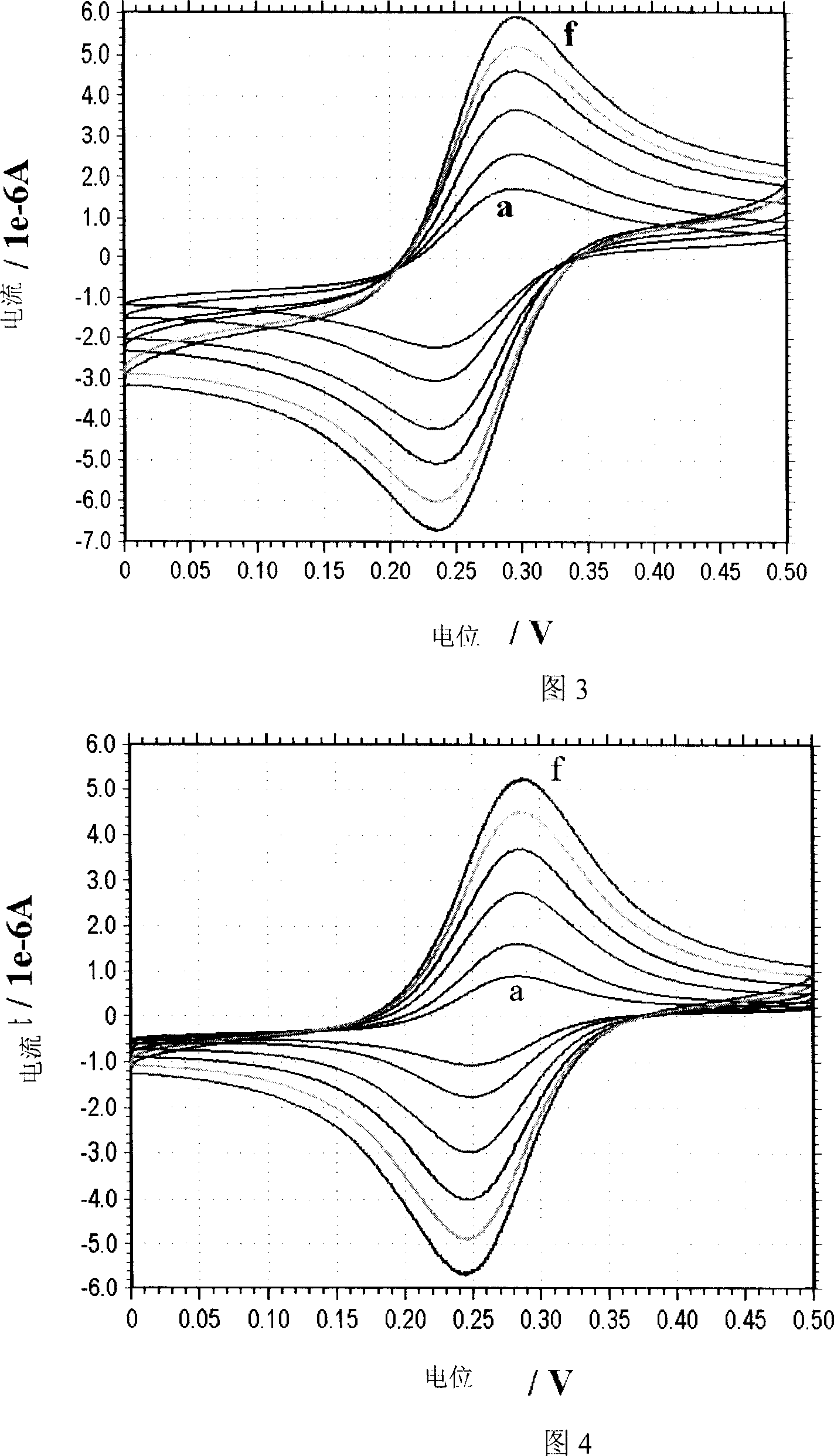

[0025] Embodiment 3: a three-electrode system is adopted, the working electrode is a metal platinum disk electrode and a platinum electrode with an AAO template on the surface, the reference electrode is an Ag / AgCl electrode, the counter electrode is a platinum wire, and the solution is 1mM K3 Fe(CN) 6 , which contains 0.5M Na 2 SO 4 Supports electrolytes. With 10mV / s, 20mV / s, 40mV / s, 60mV / s, 80mV / s, 100mV / s, scan in the potential range from 0 to +0.5V, record the cyclic voltammogram (Figure 3), redox peak The spacing is about 60mV. When there is a template, K 3 Fe(CN) 6 The reaction on the electrode is carried out through the pores of AAO, and the redox peak distance is less than 60mV (Figure 4). At the same time, the peak current decreases, and the peak current still increases with the increase of the scan rate. Exhibits a good linear relationship. The electrochemical effective area can be obtained from the slope of the straight line. Further, the effective pore densi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com