Anisotropic conductive connector for wafer inspection, production method and application therefor

An anisotropic, manufacturing method technology, applied in the direction of conductive connection, electrical component connection, elastic body connector, etc., can solve the problems of complicated manufacturing process, high manufacturing cost of anisotropic conductive connector, and increased wafer inspection cost , to achieve the effect of reliable electrical inspection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0248] The present invention is not limited to the above-described embodiments, and various modifications as follows are possible.

[0249] (1) In the anisotropic conductive connector, in addition to the connecting conductive portion 21 , a non-connecting conductive portion not electrically connected to the inspected electrode of the wafer may be formed in the elastic anisotropic conductive film 20 . Next, an anisotropic conductive connector having an elastic anisotropic conductive film and forming a non-connection conductive portion will be described.

[0250] Fig. 19 is an enlarged plan view showing another example of the elastic anisotropic conductive film of the anisotropic conductive connector of the present invention. For the elastic anisotropic conductive film 20 of this anisotropic conductive connector, in the thickness direction (that is, the direction perpendicular to the page in FIG. A plurality of conductive parts 21 for connection are arranged in two rows accordi...

Embodiment 1

[0276] [Production of frame board]

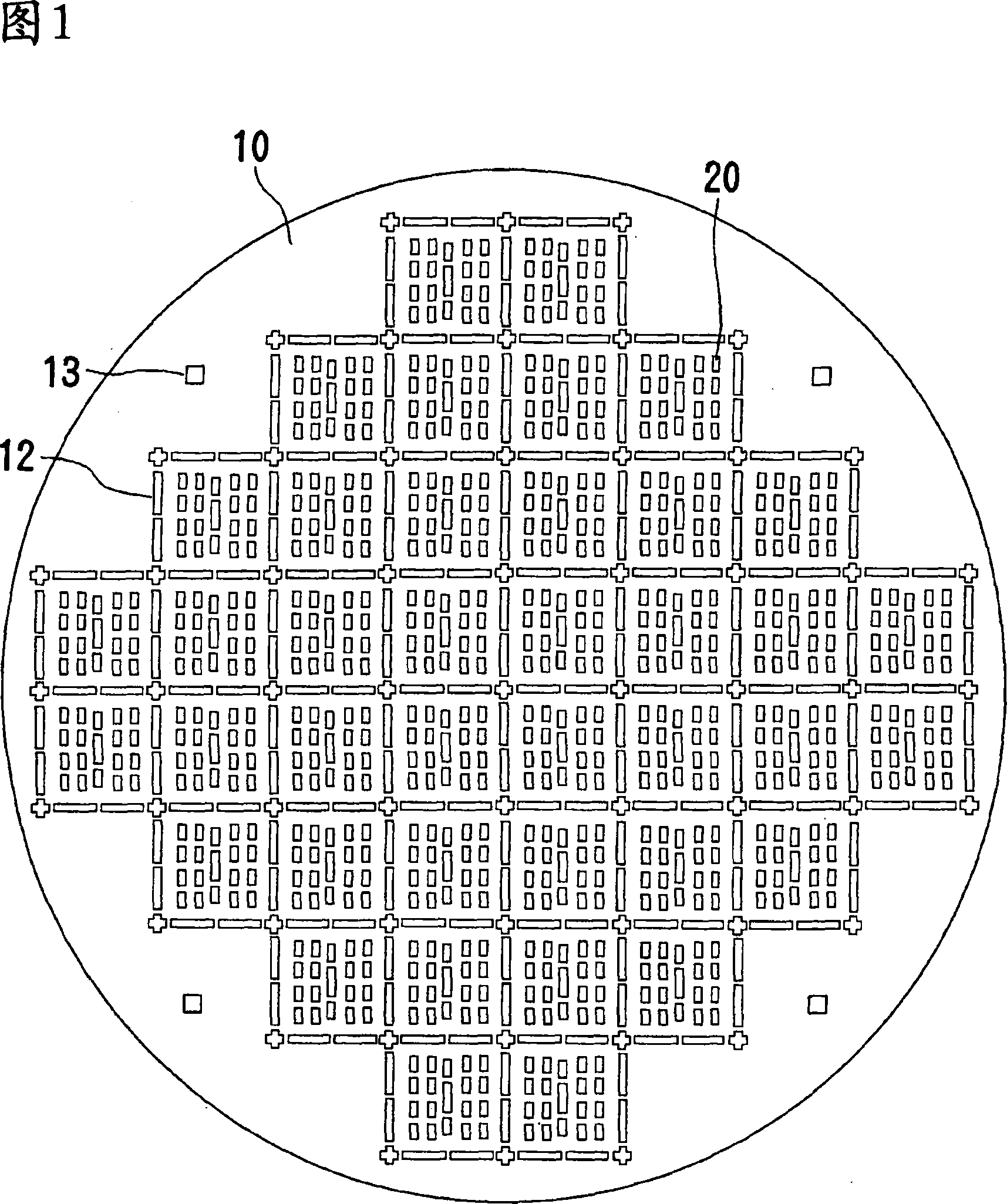

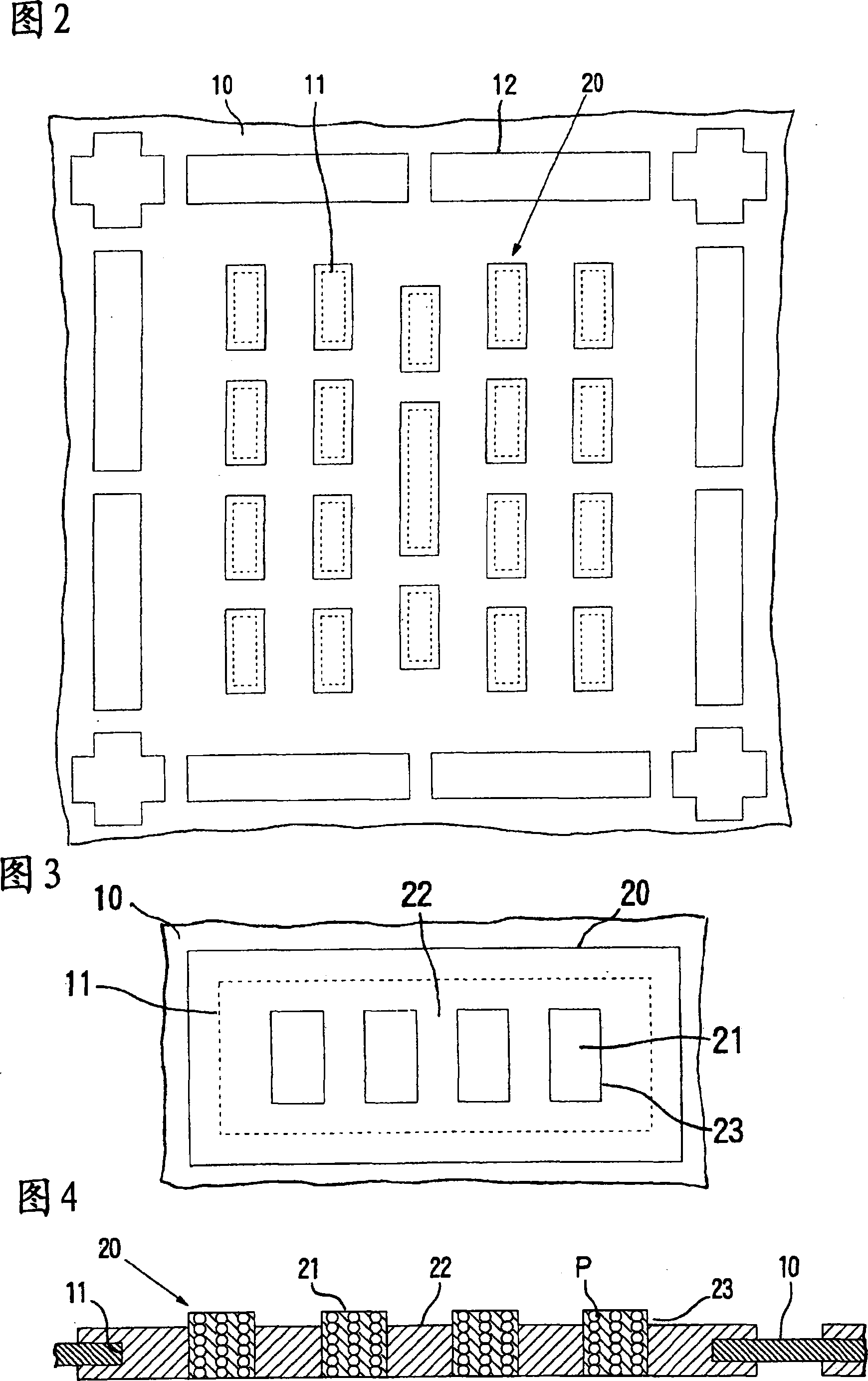

[0277] According to the structure shown in Fig. 26 and Fig. 27, according to the following conditions, the frame plate (10) with a diameter of 8 inches (10) having 393 openings (11) formed corresponding to each inspected electrode region of the above-mentioned test wafer W1 was produced.

[0278] The frame plate (10) is made of Kovar iron-nickel-cobalt alloy (linear thermal expansion coefficient 5×10 -6 / K), and its thickness is 60 μm. The openings (11) of the frame plate (10) each have a horizontal (left-right direction in FIGS. 26 and 27 ) dimension of 5.5 mm and a longitudinal (vertical direction in FIGS. 26 and 27 ) dimension of 0.4 mm.

[0279] A circular air circulation hole (12) with a diameter of 1mm is formed at the center between longitudinally adjacent openings (11).

[0280] [Manufacturing of spacers for molding]

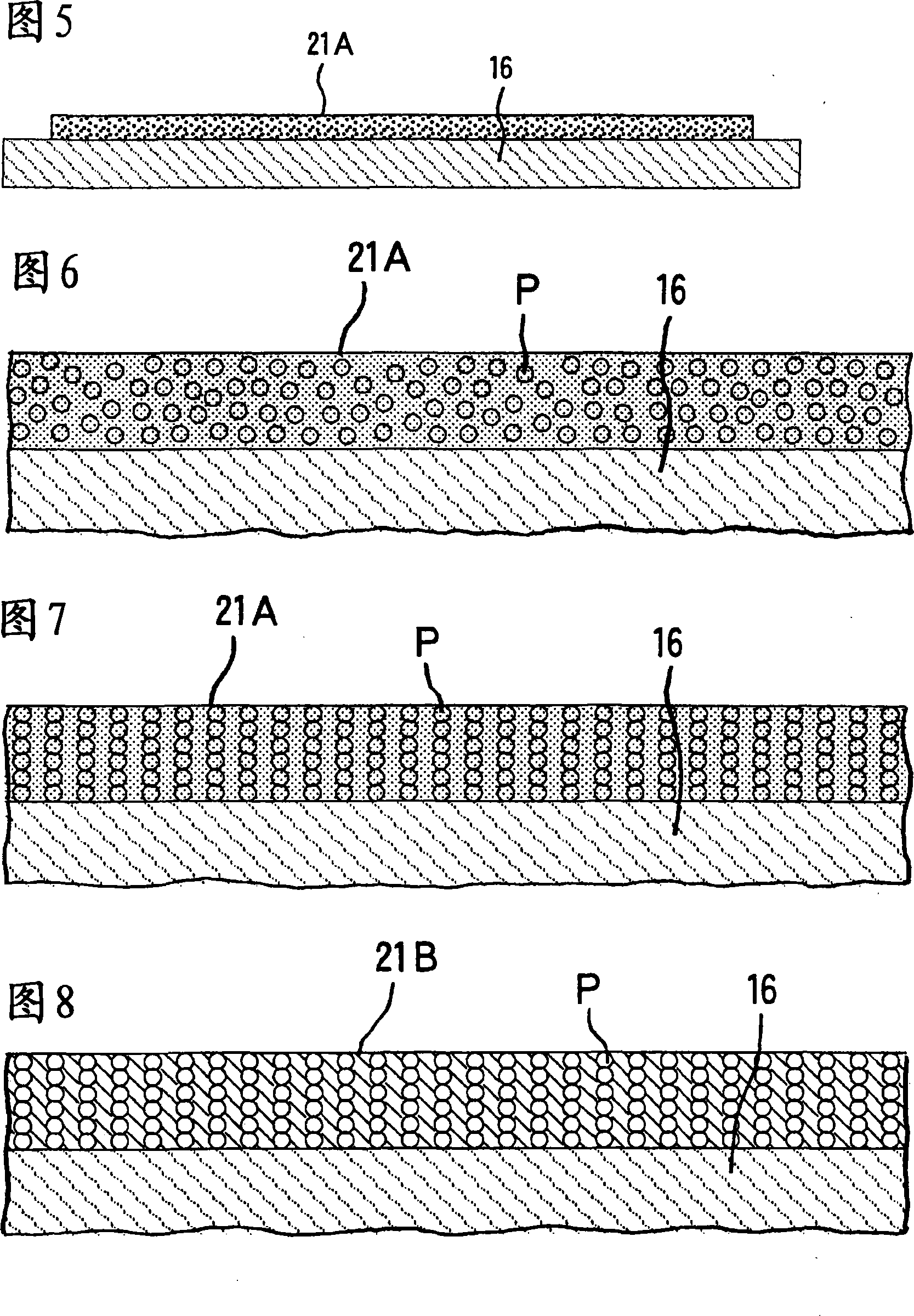

[0281] Two spacers for forming an elastic anisotropic conductive film having a plurality of openings formed corr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com