Method and system for solubilizing protein

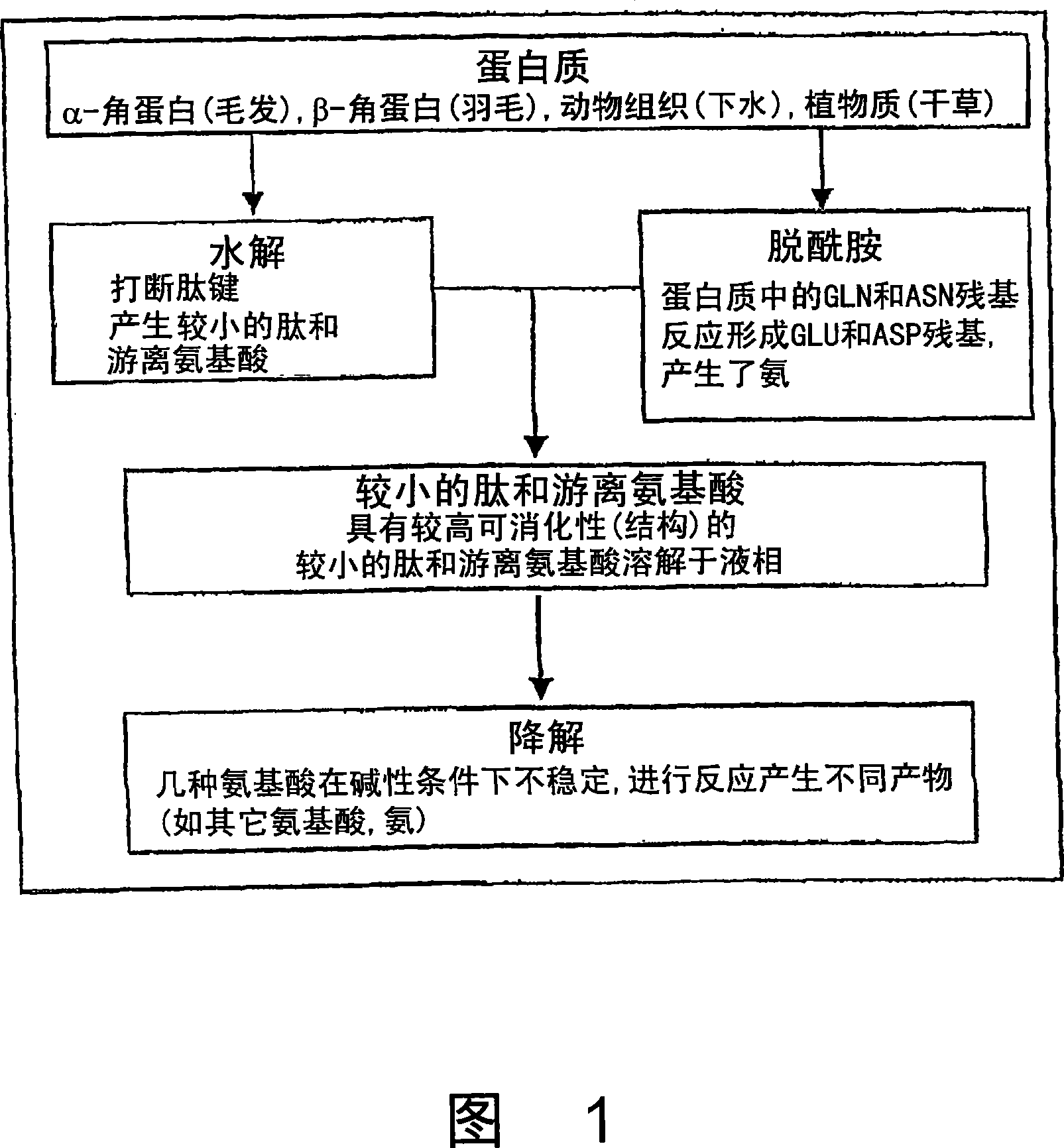

A protein and protein source technology, applied in the field of dissolving proteins, can solve problems such as not being suitable for destroying prions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

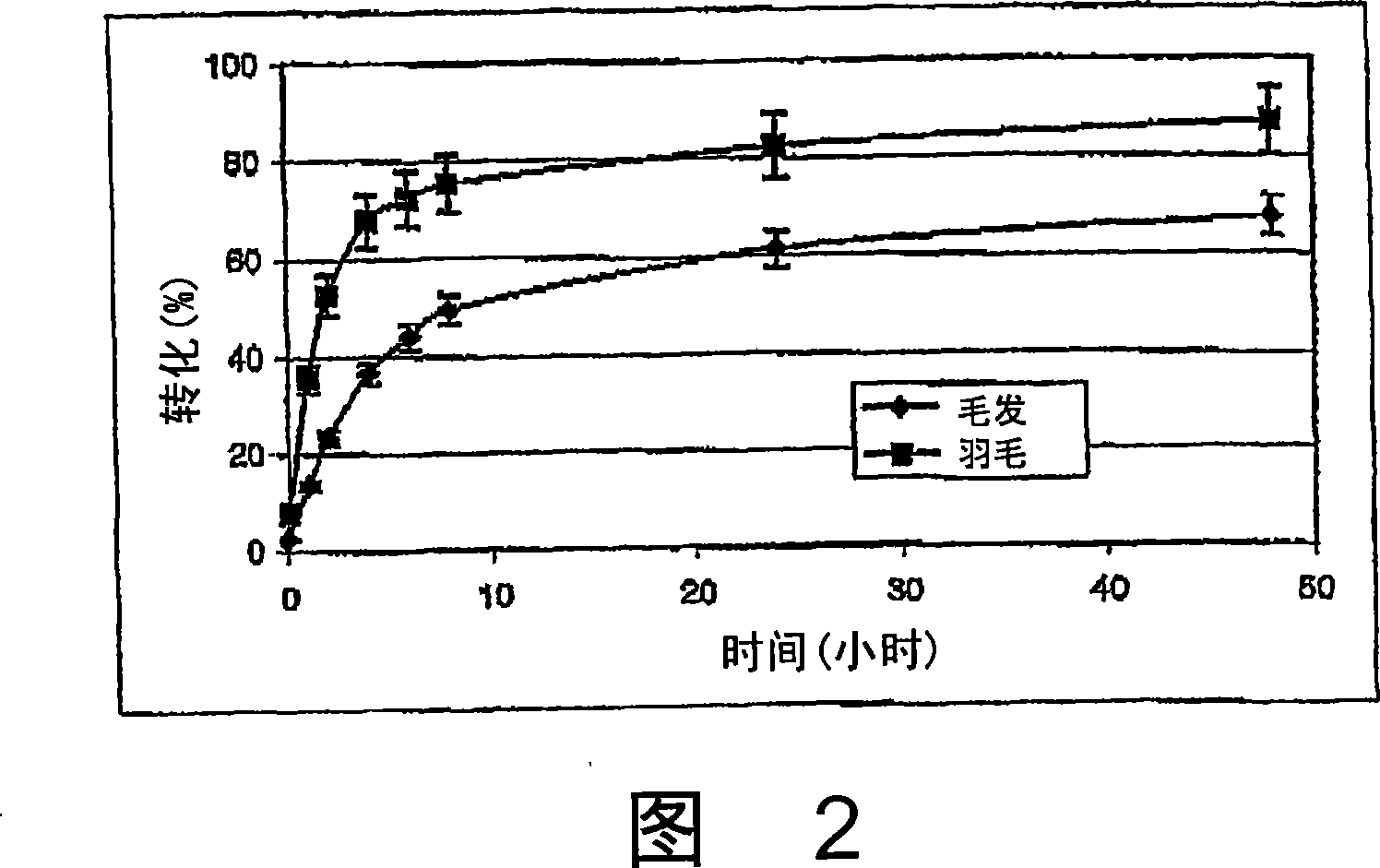

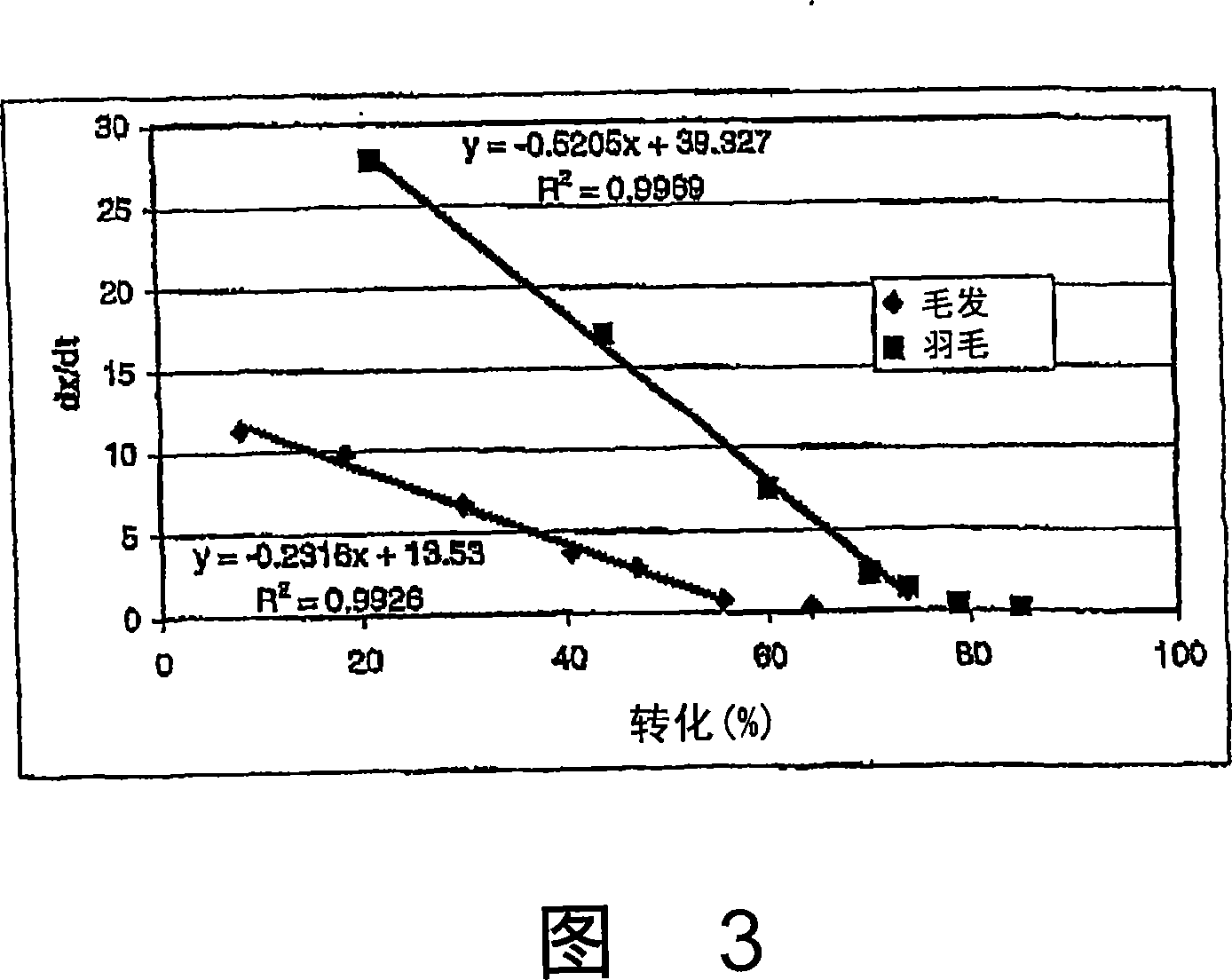

[0146] Example 1: General method and equipment:

[0147] The following general methods and equations are used in this embodiment:

[0148] Two different methods are used to determine the concentration of different compounds in liquid products and raw materials: determination of amino acid composition by HPLC method (by the Protein Chemistry Laboratory of Texas A&M University); Extension of Soil, Water and Food Testing Laboratory of Texas A&M University (Extension) Soil, Water and Forage Testing Laboratory) used standard methods to determine total Kjeldahl nitrogen and minerals.

[0149] The digestibility of lignocellulosic materials was determined by the 3-d digestibility test by DNS method. If necessary, grind the biomass to a suitable size. A Thomas-Wiley laboratory mill (located in the Forest Science Research Center) with several sieve apertures was used.

[0150] The NREL method is used to determine the lignin, cellulose, hemicellulose (comprehensive cellulose), ash and moistu...

Embodiment 2

[0158] Example 2: Protein solubilization in alfalfa hay

[0159] Alfalfa hay is often used in ruminant nutrition. The high digestibility of feed ensures that less feed can meet animal needs. Processing alfalfa hay produces two different products: highly digestible soluble components present in the liquid product and residual solids from delignification.

[0160] Table 3. Composition of alfalfa in different states (McDonald et al., 1995)

Alfalfa (% of dry mass)

Soluble substance

Crude protein

Fresh early flowers

Zhonghua

Blooming

Hay, sun-dried, early flowering

Zhonghua

Late flower

Mature flower

60

54

48

58

54

48

42

19

18.3

14

18

17

14

12.9

7

9

10

8

9

12

14

23

26

27

24

26

26

29

2.9

2.6

2.1

2.7

...

Embodiment 3

[0215] Example 3: Protein solubilization in soy hay

[0216] Soybeans are usually harvested to produce several food products. A large amount of useless waste products are produced during the harvesting process.

[0217] In addition, some special weather conditions (such as long dry season and long rainy season) hinder soybean growth. The low crop yield makes the harvested soybeans be used to produce animal feed (soy hay) instead of being used in the food industry.

[0218] Processing soybean hay will produce two different products: highly digestible soluble components and delignified residual solids. The high digestibility of feed ensures that less feed can meet animal needs.

[0219] The sun-dried soybean hay (ie, the leaves, stems and beans of the harvested soybean plant) was obtained from Terrabon Company; then it was ground with a Thomas-Wiley laboratory mill (Arthur H. Thomas Company, Philadelphia, Pennsylvania, USA), and Pass it through a 40-mesh sieve. Determine the moistur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com