Surface modified cadmium telluride-containing silica dioxide nano particle and its preparation method

A silicon dioxide and surface modification technology, applied in the field of nanomaterials, can solve the problems of decreased fluorescence intensity, low fluorescence intensity, and low quantum yield, and achieve good stability, good repeatability, and stable process conditions.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] (1) Take 2~5mL concentration as 2×10 -3 ~10 -5 mol / L cadmium telluride quantum dots, add 1~2mL methanol while stirring, add 1~3μL mercaptopropyltrimethoxysilane after 5~30 minutes, and continue stirring at room temperature for 15~40 minutes to obtain silica / Cadmium telluride nanoparticles, diluted for use.

[0033] (2) Take 1-10 mg of calix[4]arene, add 100-250 μL of dichloromethane to dissolve, add 50 μL of γ-[(2,3)-glycidyloxy]propyltrimethoxysilane, add 50 μL trifluoroacetic acid, sonicate for 1-3 minutes, then add 100-150μL of tetraethoxysilane, sonicate for 3-10 minutes, and then centrifuge at 8000-12000r / min for 5-10 minutes to obtain a cup[4] Aromatic hydrocarbon sol, take out the supernatant and set aside.

[0034] (3) Take 2 to 5 mL of silica / cadmium telluride nanoparticle solution, add 2 to 25 μL of calix[4]arene sol while stirring, and keep stirring for 20 to 30 minutes to make the calix[4]arene sol pass through chemical covalent The coupling is bonded ...

Embodiment 2

[0036] (1) Take 5ml concentration of 10 -3 mol / L quantum dots, add 2mL methanol while stirring, add 1μL mercaptopropyltrimethoxysilane after 20 minutes, continue stirring for 20 minutes to prepare silica / cadmium telluride nanoparticles, and then dilute to 25mL.

[0037] (2) Take 2 mg of calix[4]arene, add 200 μl of dichloromethane to dissolve, add 50 μl of γ-[(2,3)-glycidoxy]propyltrimethoxysilane, add 38 μl of trifluoroacetic acid, Sonicate for 1 minute, then add 100 μl of tetraethoxysilane, sonicate for 3 minutes, and then centrifuge at 10,000 r / min for 8 minutes to prepare a calix[4]arene sol for use.

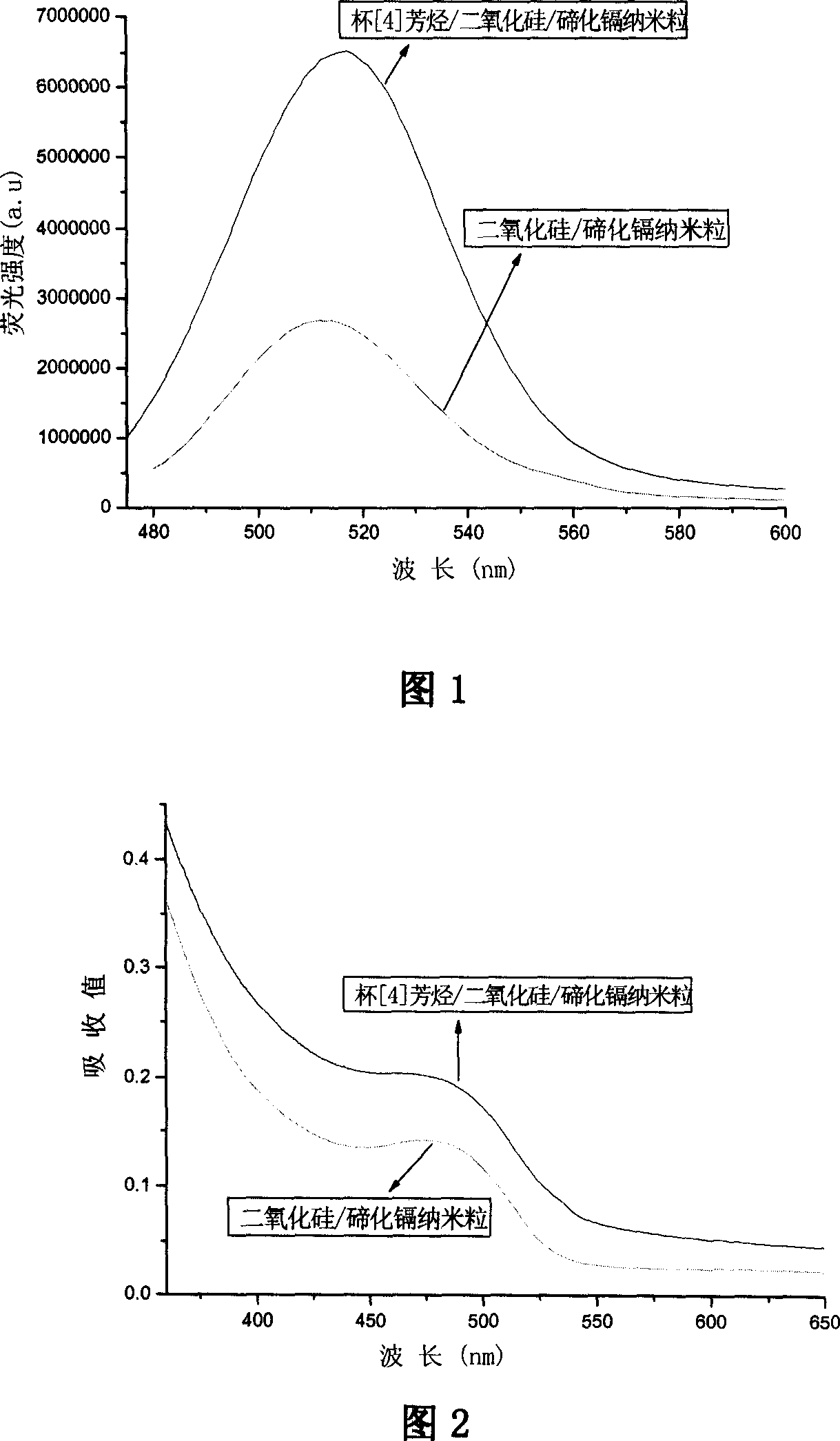

[0038](3) Take 2.5 ml of the silica / cadmium telluride nanoparticle solution in step (1), add 15 μl of cup[4]arene sol while stirring, and keep stirring for 30 minutes to make the calix[4]arene sol pass through chemical covalent The coupling is bonded on the surface of the silicon dioxide layer, and the dichloromethane therein is completely volatilized. As shown in Figure 1...

Embodiment 3

[0040] (1) Take 2~5mL concentration as 2×10 -3 ~10 -5 mol / L quantum dots, add 1~2mL methanol while stirring, add 1~3μL mercaptopropyltrimethoxysilane after 5~30 minutes, continue stirring at room temperature for 15~40 minutes, dilute and set aside.

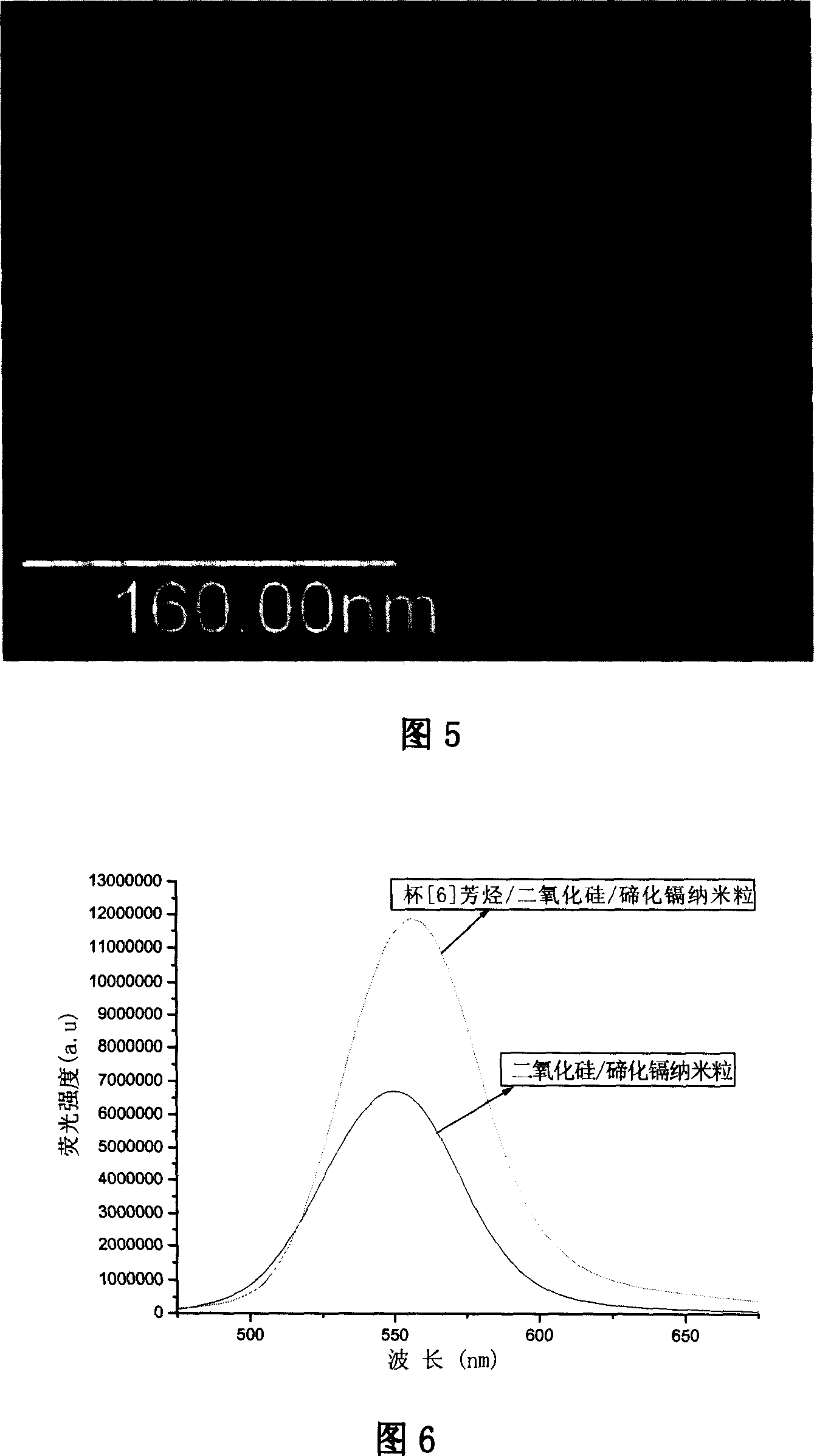

[0041] (2) Take 1-10 mg of calix[6]arene, add 100-250 μL of dichloromethane to dissolve, add 50 μL of γ-[(2,3)-glycidyloxy]propyltrimethoxysilane, add 50 μL trifluoroacetic acid, sonicated for 1 to 3 minutes, then added 100 to 150 μL of tetraethoxysilane, sonicated for 3 to 10 minutes, and then centrifuged at 8000 to 12000 r / min for 5 to 10 minutes to obtain a cup[6] Aromatic hydrocarbon sol, ready for use.

[0042] (3) Take 2-5 mL of silica / cadmium telluride nanoparticles, add 2-20 μL of calix[6]arene sol while stirring, and keep stirring for 30 minutes to make the calix[6]arene sol pass through chemical covalent coupling bonds Combined on the surface of the silicon dioxide layer, and let the dichloromethane in it completely v...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com