Catalytic combustion evaporator

A catalytic combustion and evaporator technology, applied in combustion chambers, combustion methods, combustion equipment, etc., can solve the problems that cannot meet the requirements of compact and efficient hydrogen production systems, the utilization of waste heat from combustion exhaust gas is not considered, and the efficiency is low. Excellent evaporation effect, reduced heat transfer resistance, uniform distribution effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

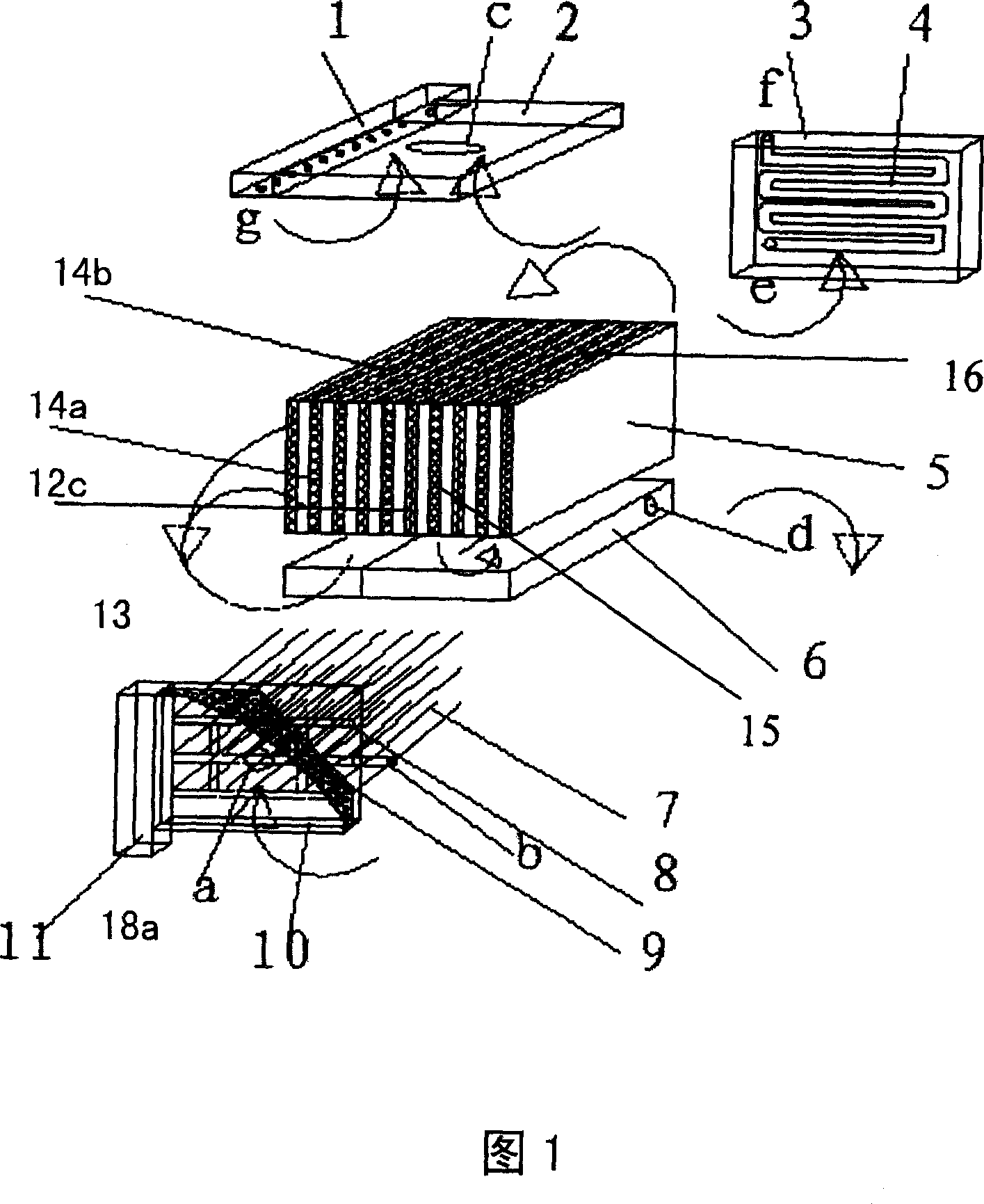

[0025] As shown in Figure 1, it is a catalytic combustion evaporator of the present invention. The catalytic combustion evaporator body 5 is a rectangular body. In the body 5, there are nineteen chambers from left to right, of which ten combustion chambers 12, nine The evaporation chamber 14, the combustion chamber 12 and the evaporation chamber 14 are all flat rectangular cavities, and the cavities are of plate-fin structure to improve the heat transfer film coefficient of the cavities. The combustion chamber 12 is open at the front and rear, and the internal fluid flows in the front and rear direction, with the upper and lower chamber side walls, and the left and right heat conduction plates 15; 16. The combustion chamber 12 and the evaporation chamber 14 are arranged alternately, and are in close contact with each other through the heat conduction plates 15 and 16, and the fluids in the two adjacent chambers flow in cross-flow. The combustion chamber 12 forms ten parallel p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com