Loop type heat pipe structure

A technology of heat pipes and loops, applied in the field of connection structure between evaporators and their tube loops, which can solve problems such as blockage, uncontrollable cleanliness and vacuum, and affecting heat transfer efficiency of finished products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

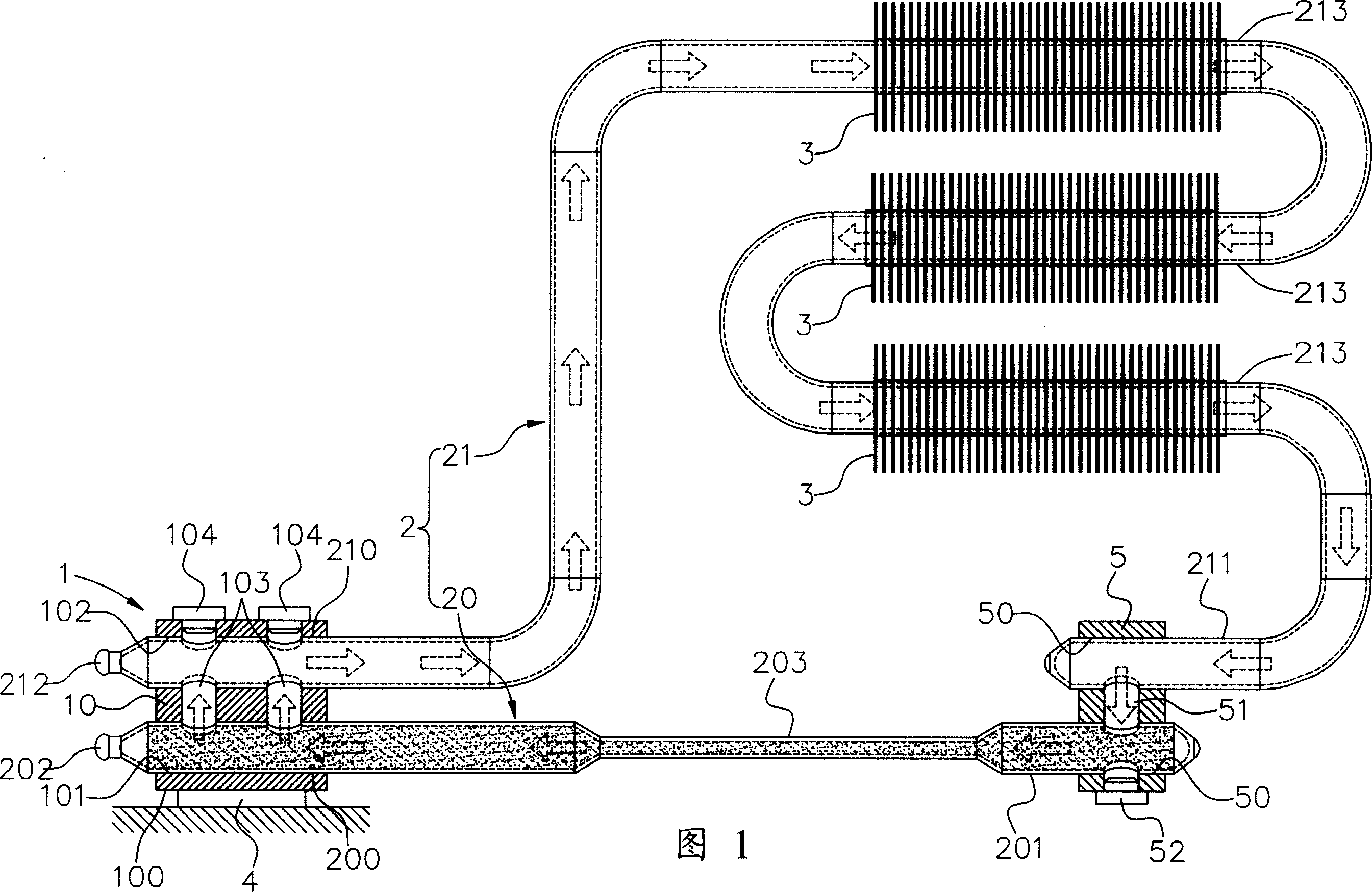

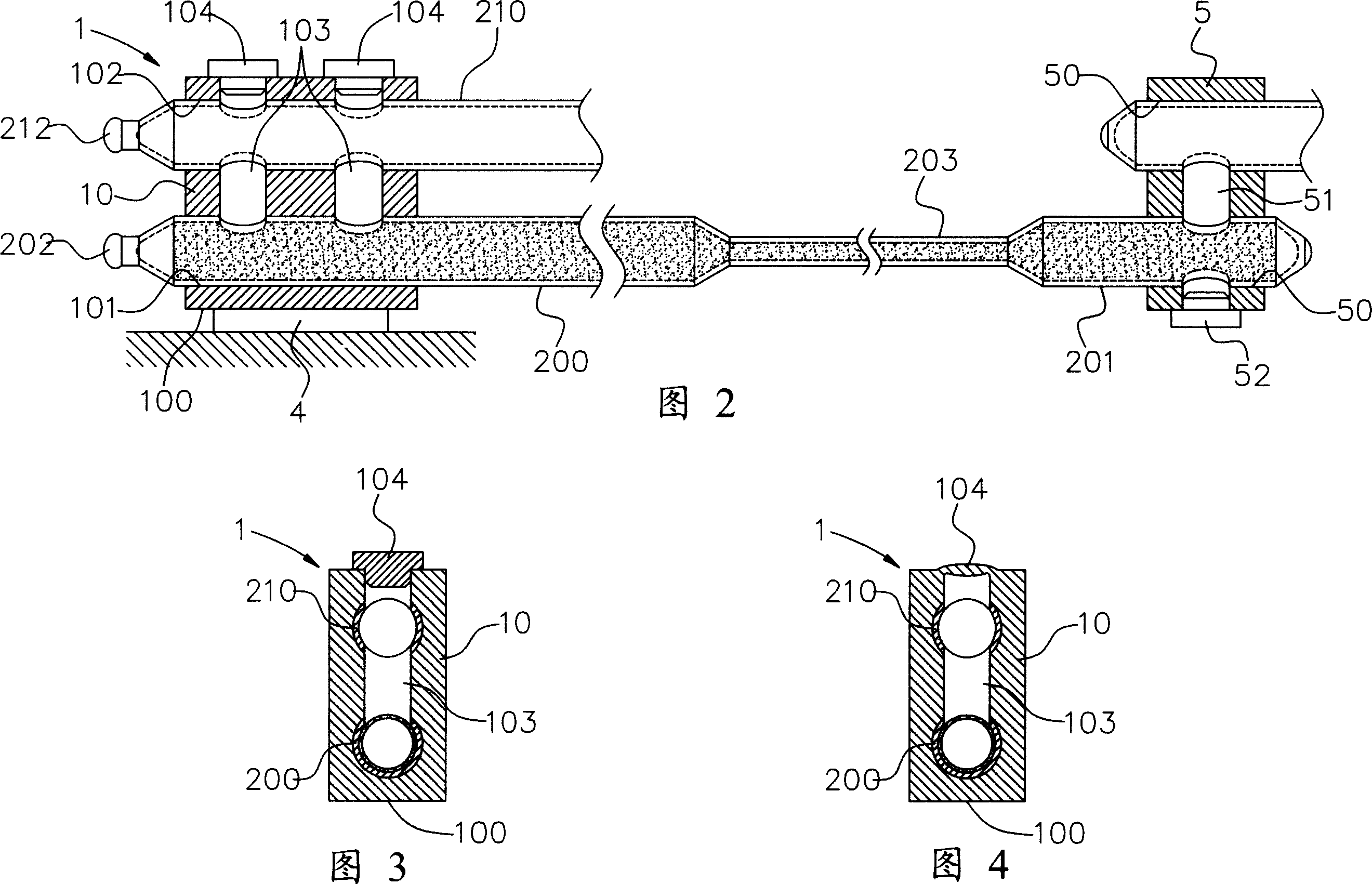

[0038] In order to further understand the features and technical contents of the present invention, please refer to the following detailed description and drawings related to the present invention. However, the drawings are provided for reference and illustration only, and are not intended to limit the present invention.

[0039] Referring to FIG. 1 , the present invention provides a loop heat pipe structure, which generally includes an evaporator 1 and a closed pipe 2 . in:

[0040] The evaporator 1 is the heat-receiving part of the loop-type heat pipe, which has an evaporation body 10 made of a heat-conducting material, such as aluminum or copper. Therefore, the evaporating body 10 is essentially a heat spreader, and has a contact surface 100 for being flat against the heat source 4 . The heat source 4 refers to electronic heating components, usually a central processing unit (CPU), but not limited thereto. In addition, at least two accommodating holes 101 , 102 and at lea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com