System comprising duel-fuel and after treatment for heavy-heavy duty diesel (HHDD) engines

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

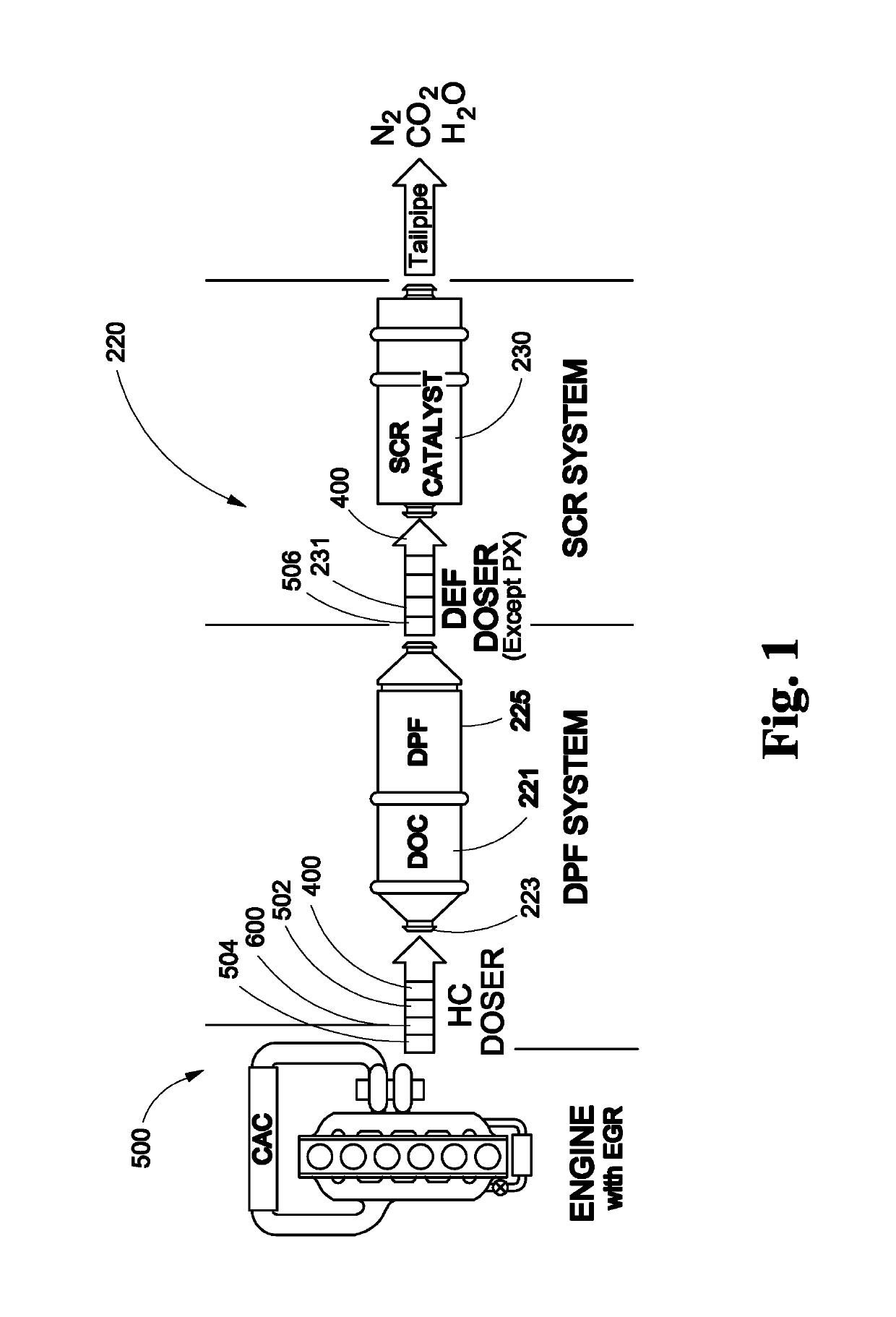

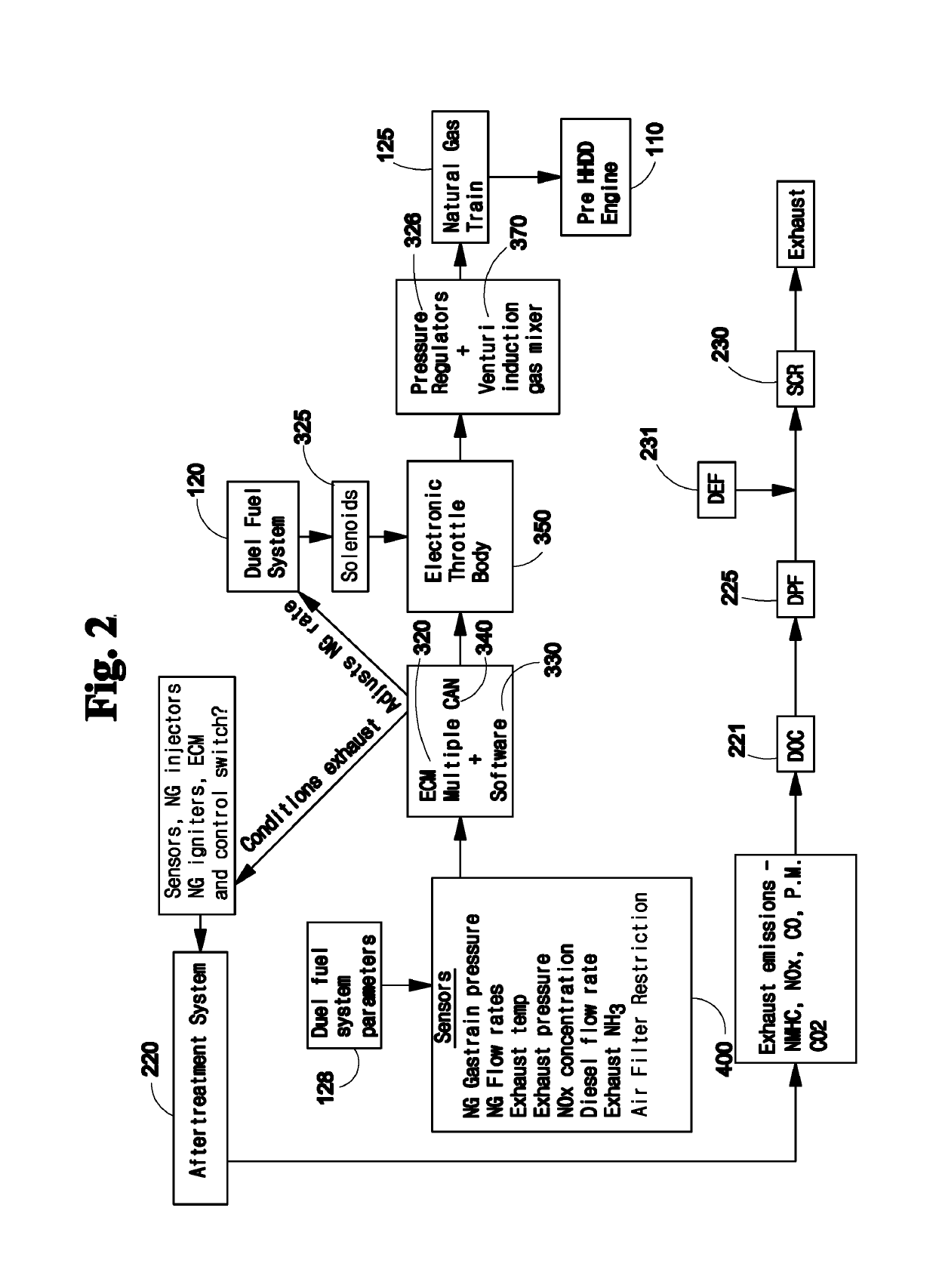

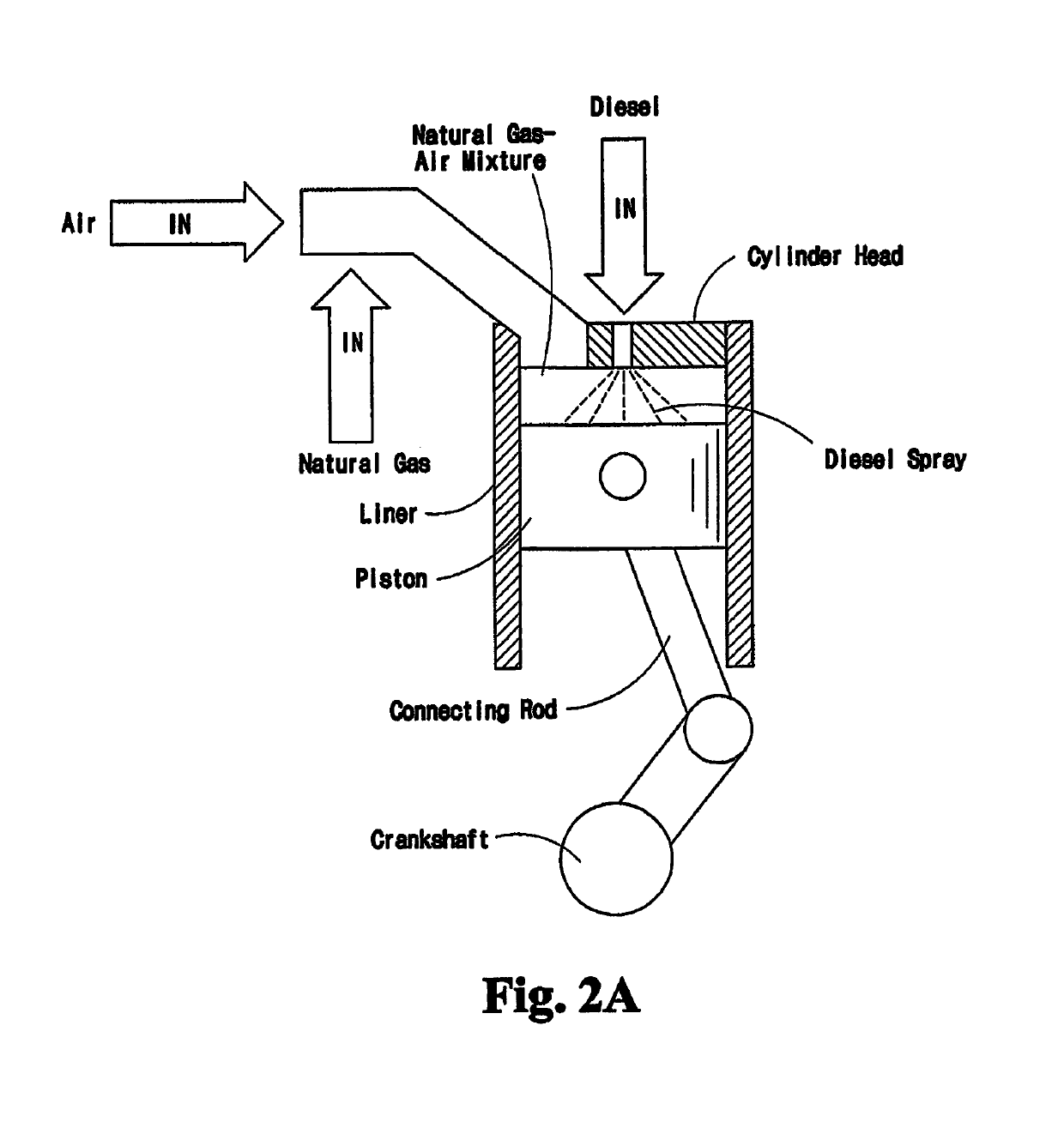

[0032]In the embodiment employed with 2010 and newer HHDD engines, the APG V6000 (or V6000) 1 (FIG. 2) of the present invention in its simplest embodiment is combined with a 2010 or newer Heavy-Heavy Duty Diesel (HHDD) engine 110 and comprises and APG Dual Fuel system 120 substituting an amount of natural gas (NG) 25 for diesel fuel 130 (see FIGS. 2, 2a and 2b.) and an exhaust thermal management system 500 comprising means to rapidly heat the factory-provided DOC / DPF and SCR systems.

[0033]For pre-2010 HHDD engines the APG V6000 is combined with a pre-2010 Heavy-Heavy Duty Diesel (HHDD) engine 110 and comprises an APG Dual-Fuel system 120 for substituting an amount of natural gas (NG) 25 for diesel fuel 130 (see FIGS. 2, 2a and 2b.). The APG V6000 1 comprises, a “full” after-treatment system 220, and at least one Electronic Control Module(s) (ECM's) 320, with appropriate software 330, utilizing multiple Communication Area Network (CAN) channels to precisely control NG 25 fuel substit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com