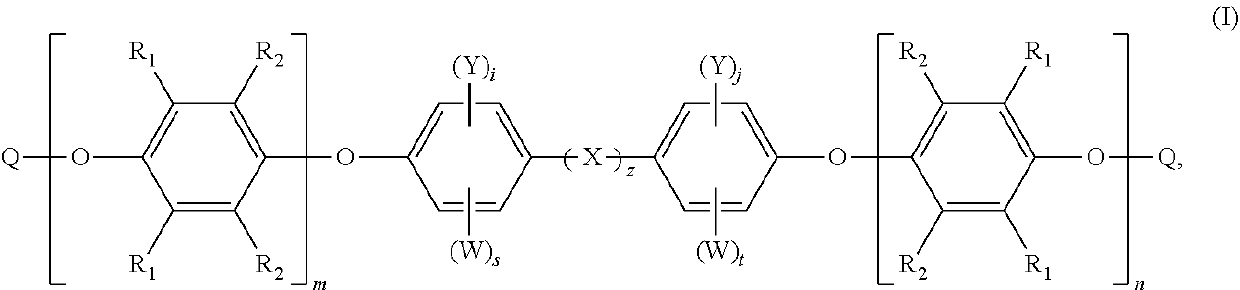

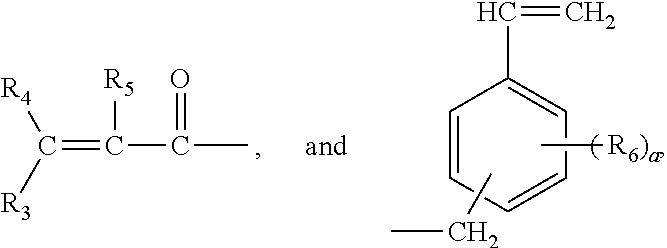

Structure of phosphorous-containing functionalized poly(arylene ether), composition containing the same, and copper clad laminate

a functionalized poly and phosphorous technology, applied in the field of compounds, can solve the problems of poor compatibility between the poly(arylene ether) and other thermosetting resins, insufficient processing of traditional poly(arylene ether), and higher heat expansion coefficien

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

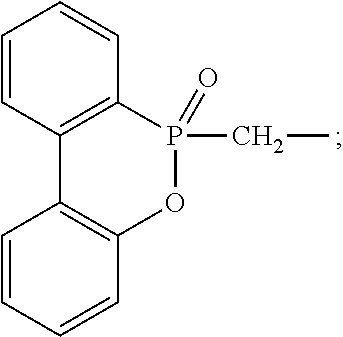

reference example 1

[0057]376 g bisphenol, 210 g formaldehyde aqueous solution (mass concentration is 37%), and 24 g NaOH were put into a reactor and then stirred. The temperature was increased to 50° C. and then kept for 3 hours. Next, the temperature was increased to 85° C. and then kept for 3 hours. Afterwards, 480 g n-butanol was added and then refluxed for 12 hours. The temperature was then decreased to 55-60° C. About 324 g n-butanol was removed by reduced pressure distillation to obtain an intermediate. The intermediate was added with 380 g DOPO (9,10-Dihydro-9-oxa-10-phosphaphenanthrene-10-oxide), and the material temperature was progressively increased from 80° C. to 180° C. in 2 hours. The pressure was decreased at 130° C. to ensure timely discharge the n-butanol. The temperature was kept at 180° C. for 1 hour. The material temperature was decreased to 130° C. About 1000 g toluene was added and then stirred for 0.5 hour. The material was discharged to obtain a DOPO-containing dihydroxyl biphe...

reference example 2

[0058]456 g bisphenol A, 210 g formaldehyde aqueous solution (mass concentration is 37%), and 24 g NaOH were put into a reactor and then stirred. The temperature was increased to 50° C. and then kept for 3 hours. Next, the temperature was increased to 65° C. and then kept for 3 hours. Afterwards, 480 g n-butanol was added and then refluxed for 12 hours. The material temperature was then decreased to 55-60° C. About 324 g n-butanol was removed by reduced pressure distillation to obtain an intermediate. The intermediate was added with 380 g DOPO (9,10-Dihydro-9-oxa-10-phosphaphenanthrene-10-oxide), and the material temperature was progressively increased from 80° C. to 175° C. in 2 hours. The pressure was decreased at 120° C. to ensure timely discharge the n-butanol. The temperature was kept at 175° C. for 2 hour. The material temperature was decreased to 130° C. About 1000 g toluene was added and then stirred for 0.5 hour. The material was discharged to obtain a DOPO-containing bisph...

reference example 3

[0059]400 g bisphenol F, 210 g formaldehyde aqueous solution (mass concentration is 37%), and 24 g NaOH were put into a reactor and then stirred. The temperature was increased to 50° C. and then kept for 3 hours. Next, the temperature was increased to 65° C. and then kept for 3 hours. Afterwards, 480 g n-butanol was added and then refluxed for 12 hours. The temperature was then decreased to 55-60° C. About 324 g n-butanol was removed by reduced pressure distillation to obtain an intermediate. The intermediate was added with 380 g DOPO (9,10-Dihydro-9-oxa-10-phosphaphenanthrene-10-oxide), and the material temperature was progressively increased from 80° C. to 180° C. in 2 hours. The pressure was decreased at 120° C. to ensure timely discharge the n-butanol. The temperature was kept at 180° C. for 2 hour. The material temperature was decreased to 130° C. About 1000 g toluene was added and then stirred for 0.5 hour. The material was discharged to obtain a DOPO-containing bisphenol F (A...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

| dielectric dissipation factor | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com