Mold material mixture containing additives for reducing casting defects

a technology of additives and molds, which is applied in the direction of manufacturing tools, foundry moulding apparatus, foundry patterns, etc., can solve the problems of increased costs, difficult to detect veins, and difficult to remove metal protrusions, so as to reduce the tendency of adhesion of mold tools, reduce the frequency of cleaning, and reduce the tendency of veining

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

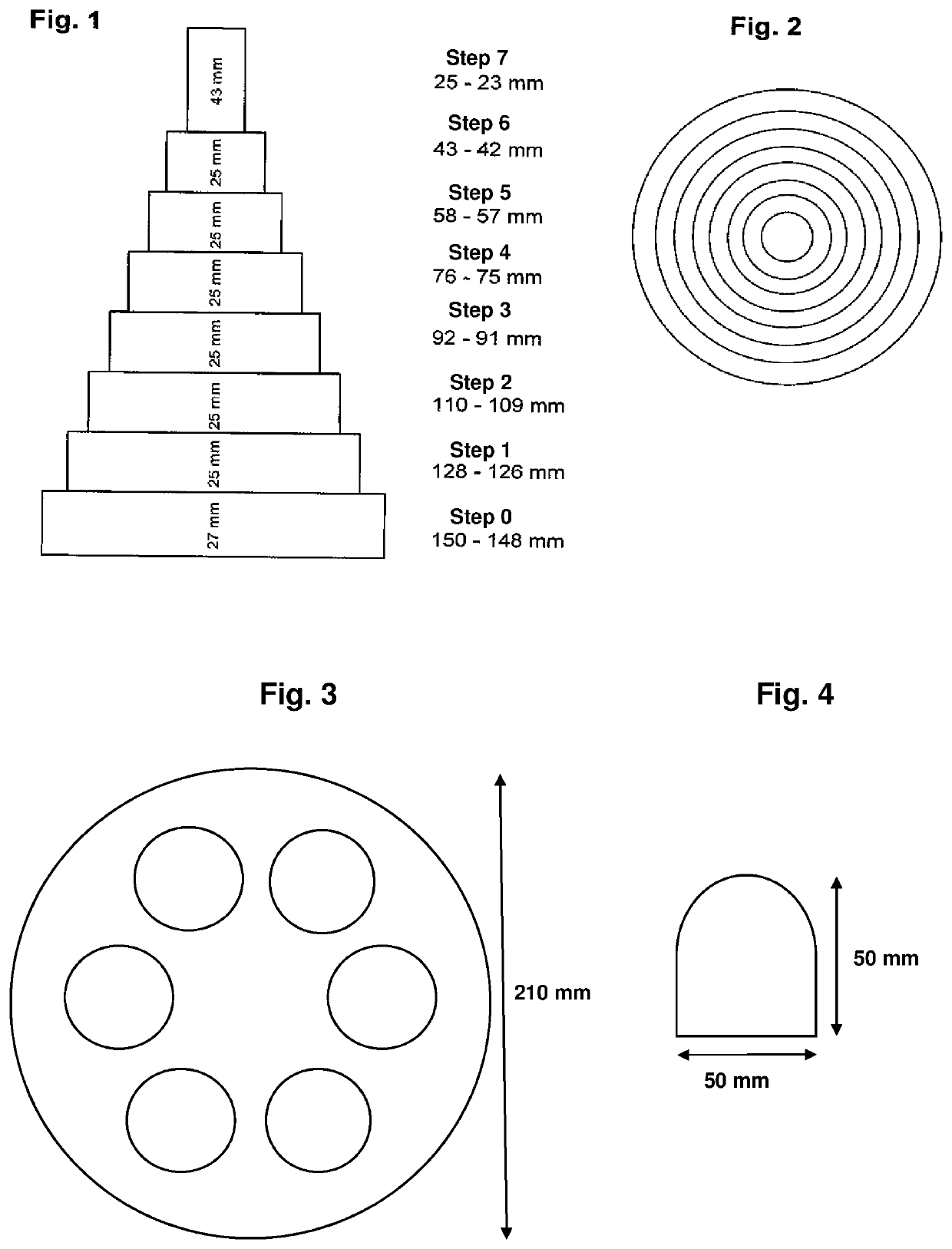

Image

Examples

Embodiment Construction

[0031]The refractory mold base materials are a suitable refractory mold base material or a mixture of multiple materials of this type, predominantly comprising quartz sand, whereby the quartz sand can be present as new sand or regenerated old sand or any mixture of the two. The inventive mold base materials used contain in particular more than 20 weight percent quartz sand with reference to the refractory mold base material, particularly preferably more than 40 weight percent, and most preferably more than 60 weight percent quartz sand.

[0032]Conventional, known materials and their mixtures can be used as a refractory mold base material for the production of casting molds. Suitable examples are quartz sand, zircon sand or chrome ore sand, olivine, vermiculite, bauxite, fireclay and socalled artificial mold base materials, i.e. mold base materials which were shaped spherically or approximately spherically (ellipsoidally, for example) by industrial processes of forming.

[0033]Examples o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com