Process for the production of synthesis gas

a technology of synthesis gas and process, applied in the field of process for the production of synthesis gas, can solve the problems of inability to adapt effectively, inability to operate conveniently apart from the design capacity, and inability to meet the needs of the user,

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example

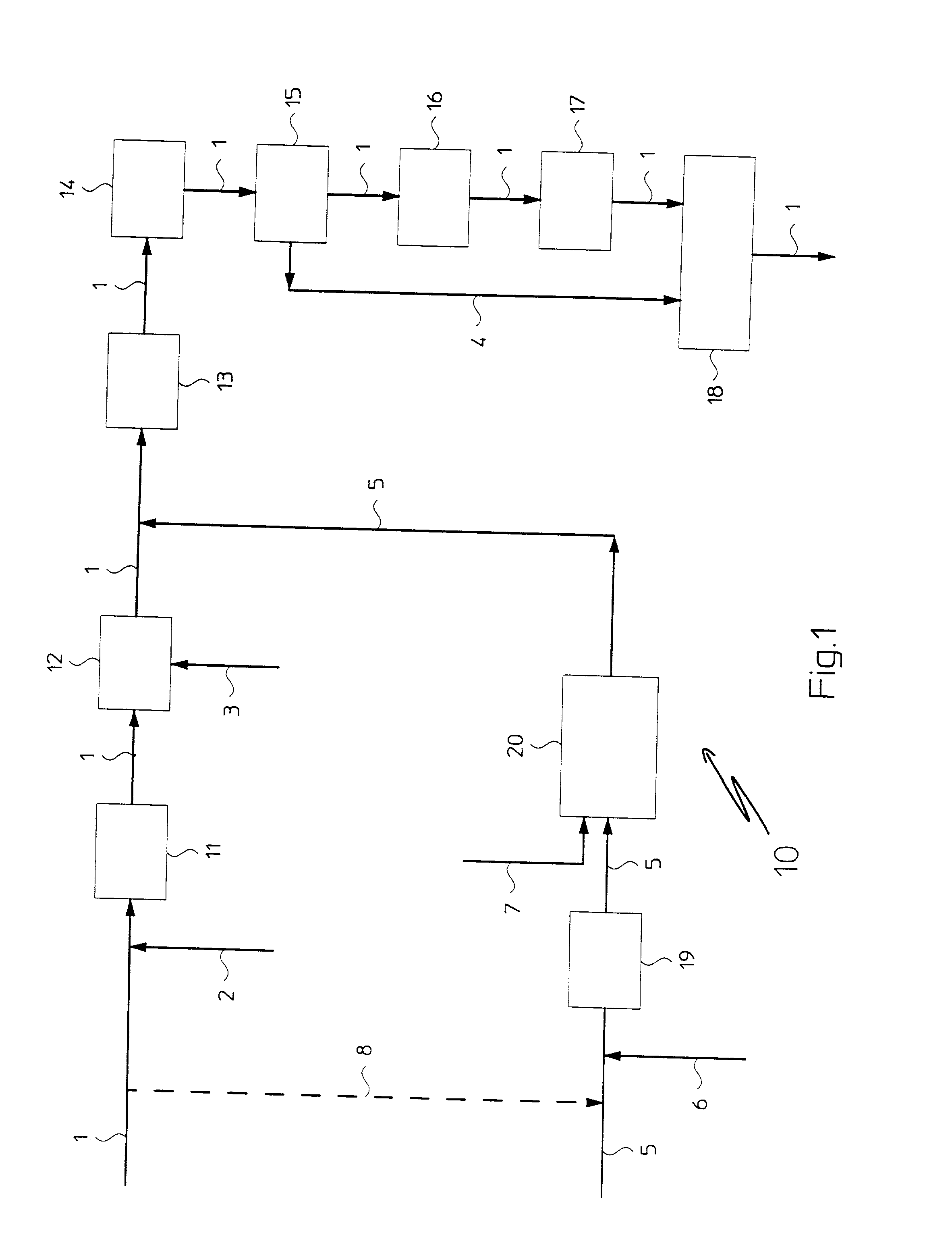

[0107] In the following example, the advantages resulting from the method of retrofitting according to the present invention are displayed.

[0108] In particular, the energy consumption relative to a capacity increase equal to 50% of an existing plant for the production of synthesis gas for obtaining ammonia is discussed.

[0109] The results of the instant example have been obtained by means of commercially available calculation algorithms.

[0110] The existing plant is of the type shown and described with reference to FIG. 1, blocks 11-17, and was designed to operated at an average production capacity of 1000 MTD of ammonia. The overall energy consumption is normally of 8300 kcal / MT of ammonia.

[0111] Natural gas is used as a source of hydrocarbons and the gas flow comprising oxygen fed to the secondary reforming section consists of air.

[0112] The primary and secondary reforming sections of the existing plant were not designed for facing a capacity increase equal to 50% but on the contrar...

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperature | aaaaa | aaaaa |

| flexible | aaaaa | aaaaa |

| energy consumption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com