Low k dielectric materials with inherent copper ion migration barrier

a technology of low k dielectric materials and migration barriers, which is applied in the direction of electrical apparatus, semiconductor devices, semiconductor/solid-state device details, etc., can solve the problems of reducing the overall dielectric constant reducing the performance of the chip, and increasing the overall dielectric constant performan

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

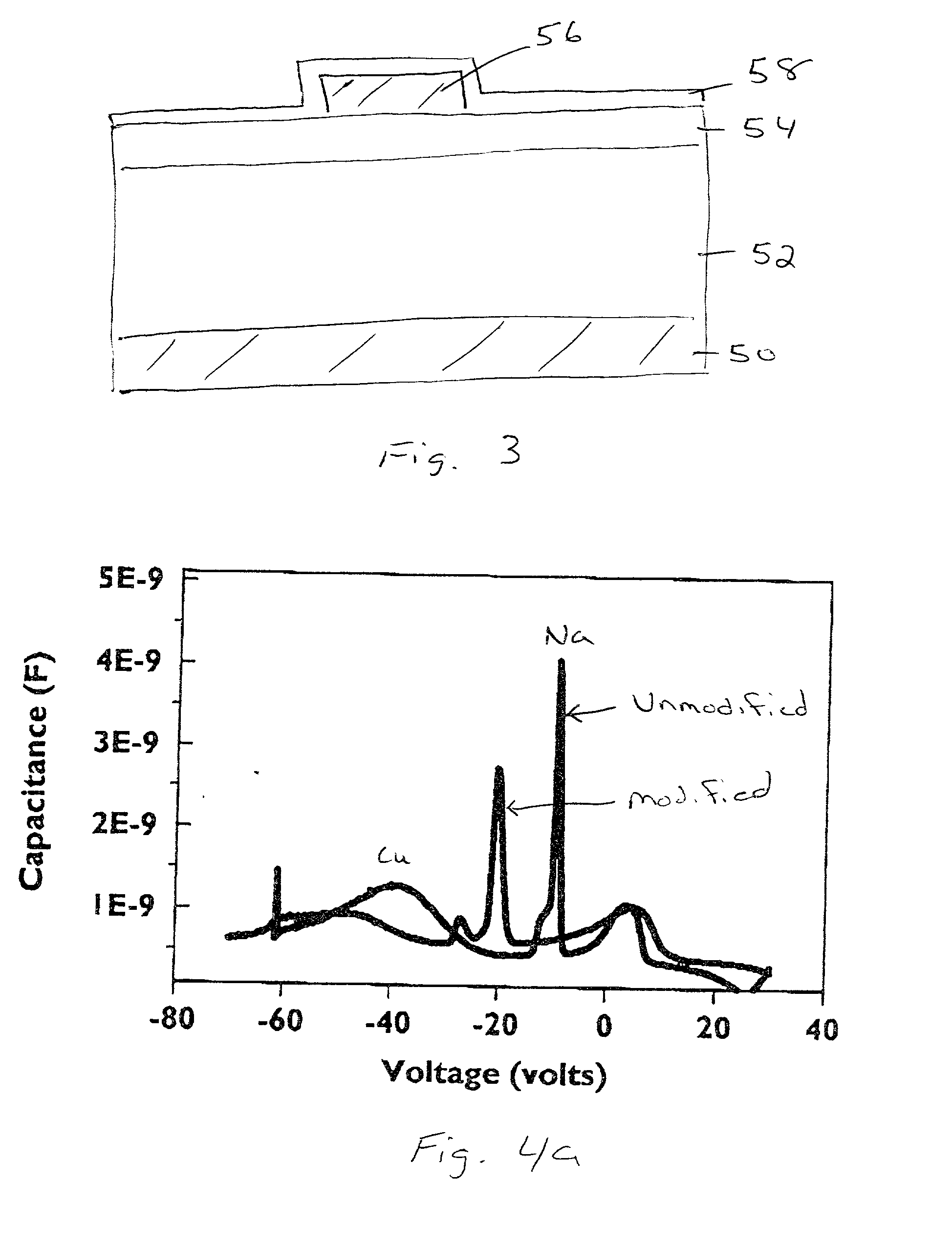

[0036] In this example, the following studies were performed on structures which contained the interlayer dielectric of the present invention, i.e. thermosetting polyarylene ether containing a phthalocyanine derivative, i.e. 2,9, 16, 23-tetra-tert-butyl-29 H, 31 H phthalocyanine, as an additive, and comparison was made to structures that contained a conventional unmodified interlayer low k dielectric (thermosetting polyarylene ether without an additive).

[0037] Bias Thermal Stress (BTS) Test

[0038] BTS tests were used as an accelerated reliability test method for degradation of the above-mentioned interlayer dielectrics.

[0039] To measure the metallic ion migration through the above-mentioned dielectric materials, a capacitor structure such as shown in FIG. 3 was employed. Specifically, the structure shown in FIG. 3 comprises a bottom W electrode 50, a Si substrate 52, an interlayer dielectric 54, Cu or Al electrode 56, and Si.sub.3N.sub.4 layer 58.

[0040] In the test, a voltage of abou...

PUM

| Property | Measurement | Unit |

|---|---|---|

| dielectric constant | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com