Freezing vegetables

a technology for vegetables and vegetables, applied in the field of freezing vegetables, can solve the problems of affecting the commercial preparation of frozen vegetables, the process is not viable, and the extra cellular fluid is easier to freeze, and the process takes several days to compl

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 2

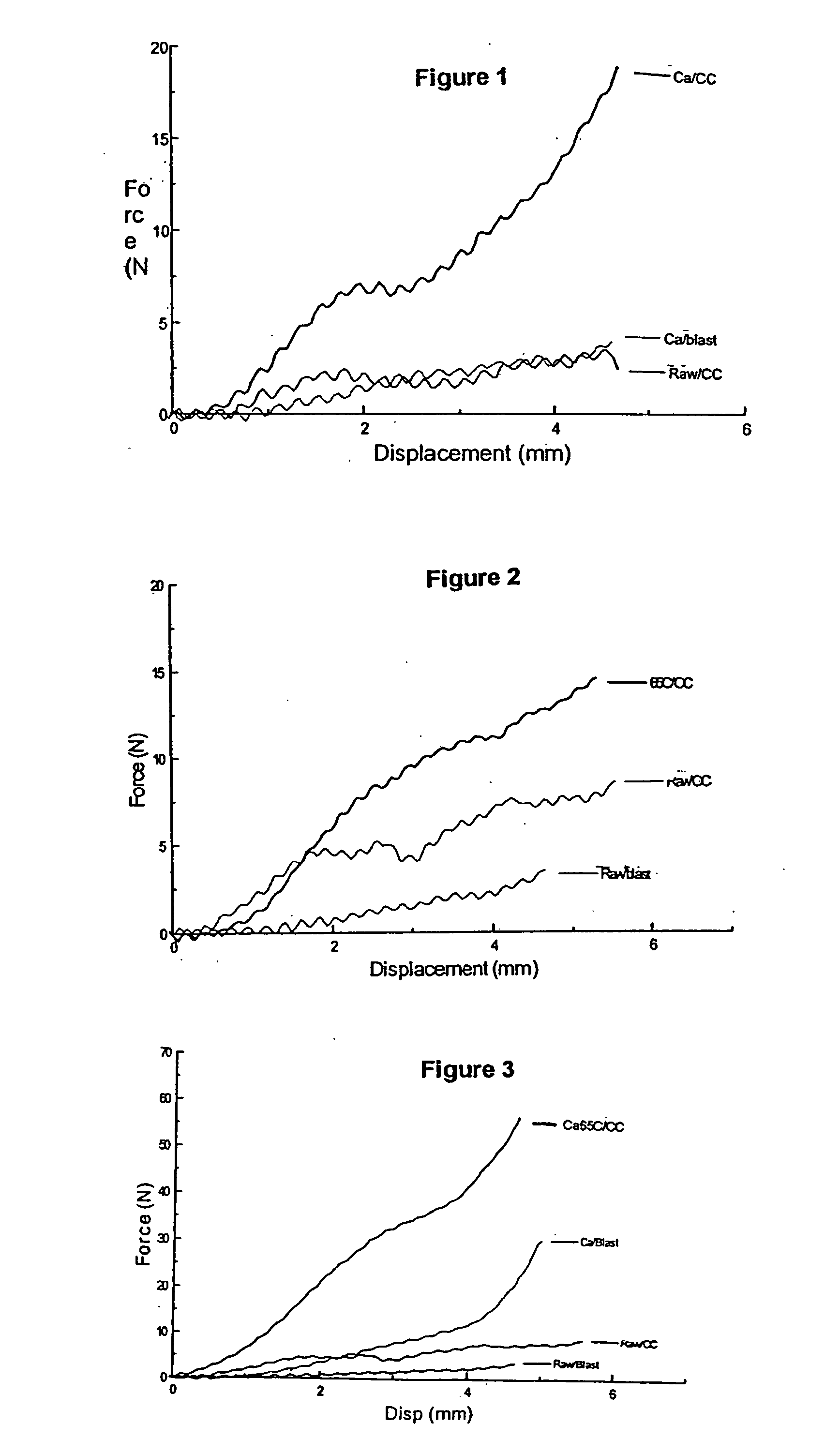

[0087] The following tests were conducted:

[0088] a) Heating at 65.degree. C. and Controlled Cooling (65C / CC)

[0089] Tomato pieces were immersed in water at 65.degree. C. for 15 minutes followed by freezing by controlled cooling. Tomato pieces were cooked from frozen.

[0090] b) No Firming Treatment and Controlled Cooling (Raw / CC)

example 3

[0099] The following tests were conducted:

[0100] a) Calcium and Low Temperature Firming and Controlled Cooling (Ca 65C / CC)

[0101] Tomato pieces were immersed in 1% calcium chloride solution at ambient temperature for 5 minutes, followed by immersion in 1% calcium chloride solution at 65.degree. C. for 5 minutes followed by immersion in 1% calcium chloride solution at ambient temperature for 5 minutes.

[0102] Thereafter the tomato pieces were frozen by controlled cooling.

[0103] Tests b), and c) were repeated as in Example 2. Test d) was the same as Test a) above, except that blast freezing was used instead of controlled cooling.

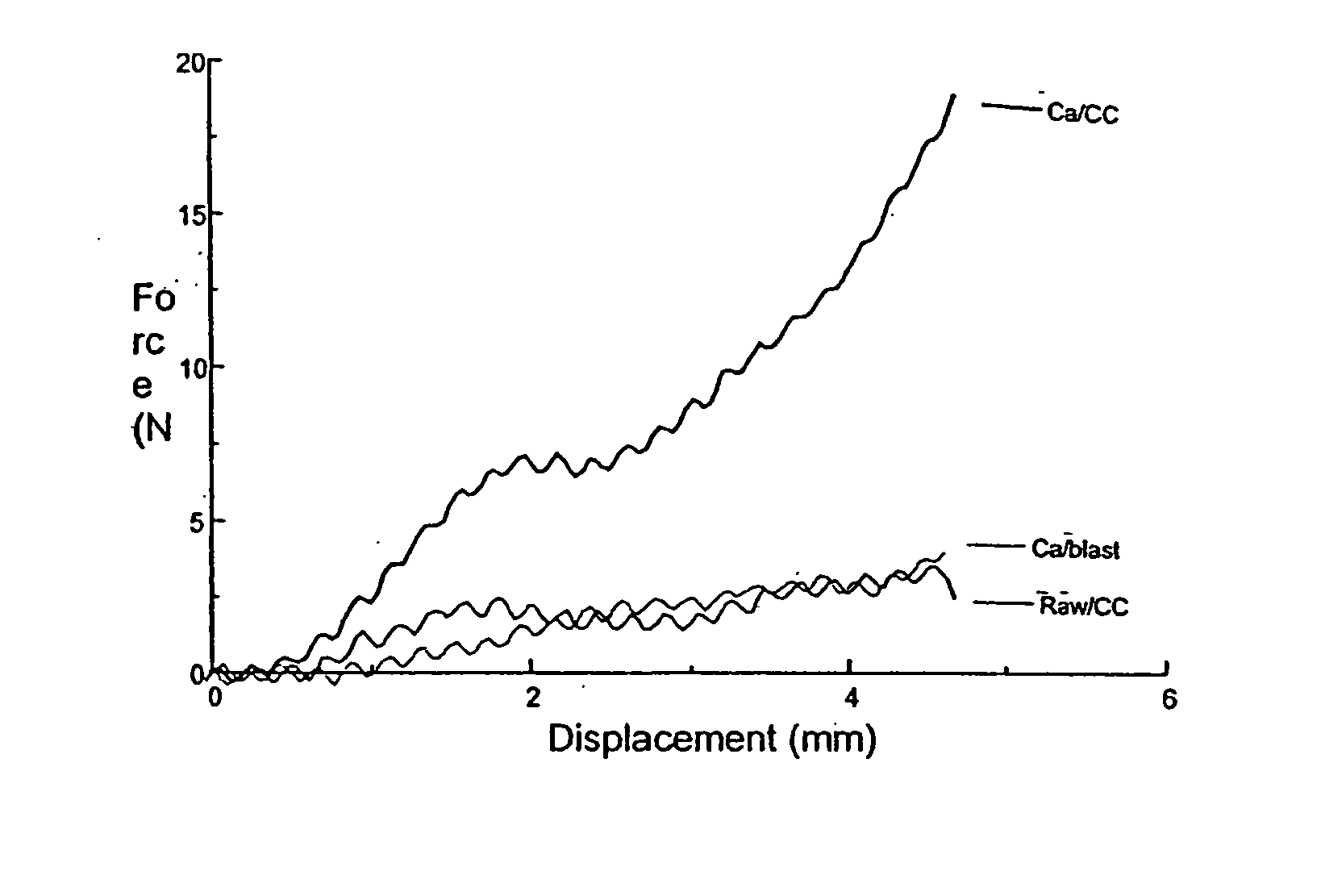

Compressive Mechanical Tests

[0104] Compressive mechanical tests were conducted on thawed samples from test a) and compared to thawed samples from b) untreated / controlled cooled (Raw / CC), c) untreated / conventionally frozen (Raw / blast) and d) calcium firming / conventionally frozen (Ca / blast). The results are reported in FIG. 3.

[0105] It will be observed from FIG. ...

example 4

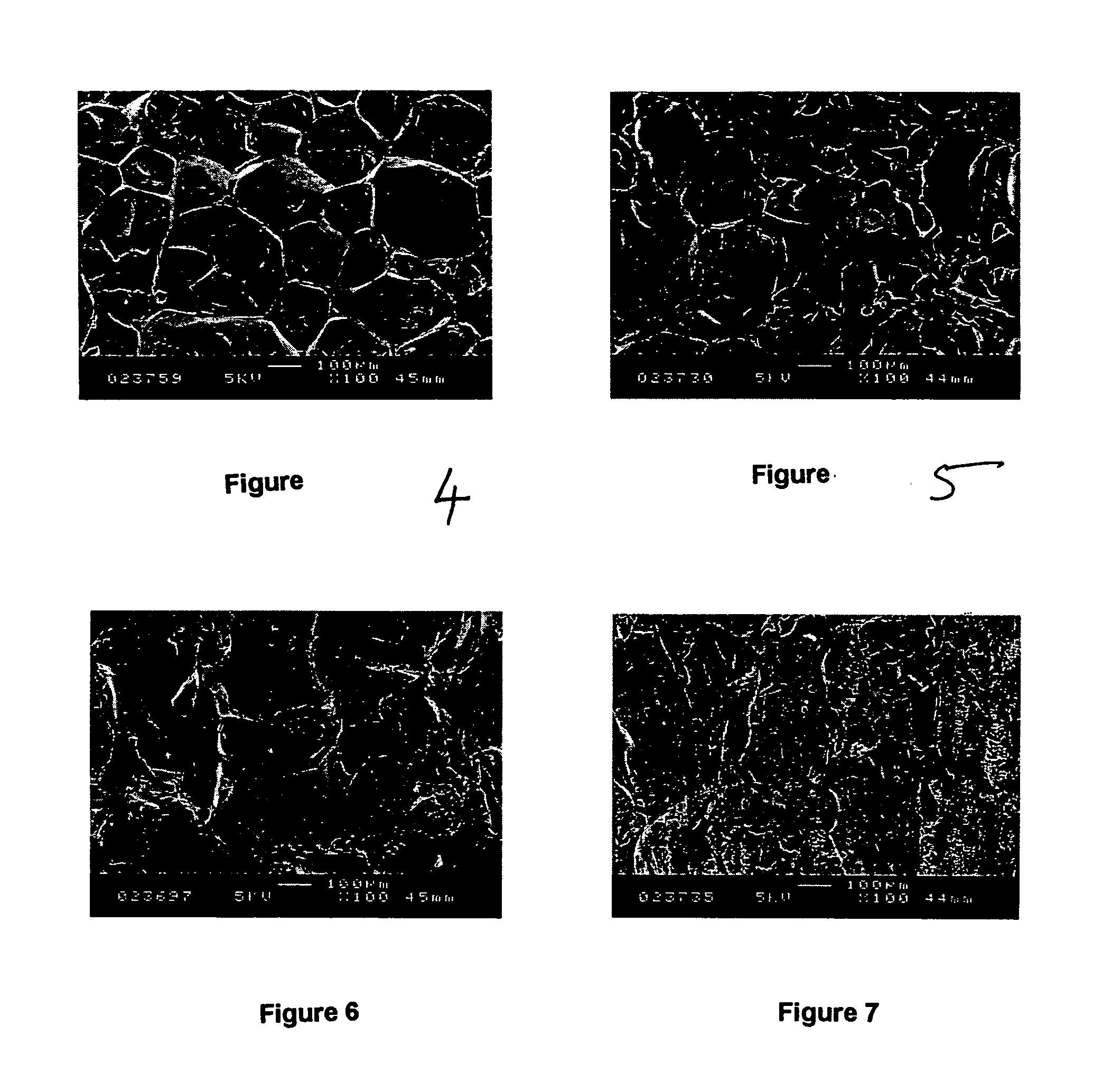

[0113] Whole new harvest potatoes (var Charlotte) were treated and analysed as follows:

[0114] Whole tubers (30 to 40g size range) were subjected to a firming treatment by immersion in water heated to 65.degree. C. for 10 minutes and then allowed to air cool for 10 minutes at room temperature. The potatoes were then blanched by immersion for 12 minutes in boiling water. Other potatoes from the same batch that had not been subjected to firming at 65.degree. C. were also blanched in boiling water for 12 minutes.

[0115] Firmed and non firmed potatoes were then frozen either conventionally in blast freezer or by controlled cooling. After freezing the tubers were thawed by immersion in water at ambient temperature. Samples from each processing regime were cut from the parenchyma region of different tubers, pieces were cut to 1 cm cubes using a scalpel blade. The pieces were compressed with a flat plate to 70 to 80% strain at a cross head speed of 2400 mm / min using a Dartec Series HC10 Serv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com