Rotor structure of line-start permanent magnet synchronous motor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

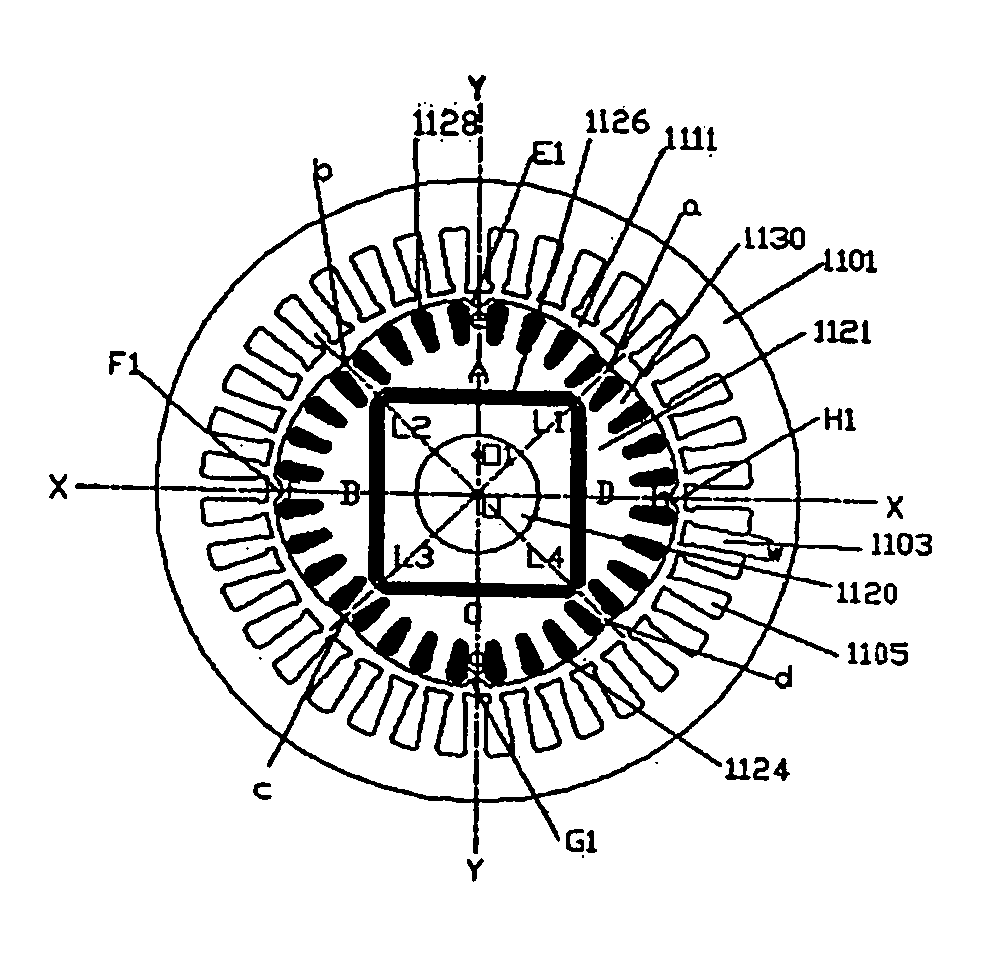

[0059] As shown again in FIG. 11, the LSPM synchronous motor 11 of the invention provides semi-circle recesses E1, F1, G1, and H1 at the midpoints e1, f1,g1, and h1 of the “first eccentric circular arcs of the surface of the magnetic poles” ab, bc, cd, and da of the fan-shaped magnetic poles A, B, C, and D. The semi-circle recesses E1, F1, G1, and H1 having diameter equals to the width w of the tooth-part 1103 of the stator 1101 and radius r=w / 2 has fillets 1136 at their both ends to connect smoothly to the “first eccentric circular arcs of the surface of the magnetic poles”1124.

second embodiment

[0060] As shown in FIG. 16 and FIG. 17, besides providing recesses E1, F1, G1, and H1 aligned with the locations of the tooth-part 1130 of the rotor 1121, the LSPM synchronous motor 11 of the invention also provides recesses E2, F2, G2, and H2 as well as E3, F3, G3, and H3 (see also FIG. 11 and FIG. 18) on each side of the recesses E1, F1, G1, and H1 having the same size and aligned with the locations of the adjacent tooth-part 1130 of the rotor 1121. This is the situation when the number of the plurality of conductive bar slots 1128 of each of the fan-shaped magnetic poles A, B, C, and D is an even number. If the number of the plurality of conductive bar slots 1128 of each of the fan-shaped magnetic poles A, B, C, and D is an odd number, the recesses E2, F2, G2, and H2 as well as E3, F3, G3, and H3 on each side of the recesses E1, F1, G1, and H1 having the same size are aligned with the locations of the adjacent conductive bar slots 1128 of the rotor 1121. Therefore, there are thre...

third embodiment

[0061] As shown in FIG. 19, in the LSPM synchronous motor 11 of the invention, the semi-circle recesses E1, F1, G1, H1 as shown in FIG. 12, as well as the semi-circle recesses E1, F1, G1, H1□E2, F2, G2, H2□ and E3, F3, G3, H3 as shown in FIG. 16 are all replaced by the “second eccentric circular arcs of the surface of the magnetic poles”1901 having center of curvature O2 offset from the center of the rotor O with the offset length OS2 of the offset OO2 and radius of curvature R2, therefore, R2−R=OS2.

[0062] As shown again in FIG. 19, in the third embodiment of the invention, the tangent points between the “second eccentric circular arcs of the surface of the magnetic poles”1901 and the “first eccentric circular arcs of the surface of the magnetic poles”1124 in the fan-shaped magnetic poles A, B, C, and D are al and a2□b1 and b2□c1 and c2□as well as d1 and d2 respectively. In other words, in the third embodiment of the invention, the “second eccentric circular arcs of the surface of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com