Thin-film field effect transistor and making method

a technology of field effect transistor and thin film, which is applied in the direction of transistors, solid-state devices, thermoelectric devices, etc., can solve the problems of imposing a certain limit in reducing the cost of tft manufacture, causing slight defects, and ordinary metal-based semiconductors used in the art cannot avoid the problem, etc., to achieve greater carrier mobility, minimize defects, and reduce the effect of manufacturing cos

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

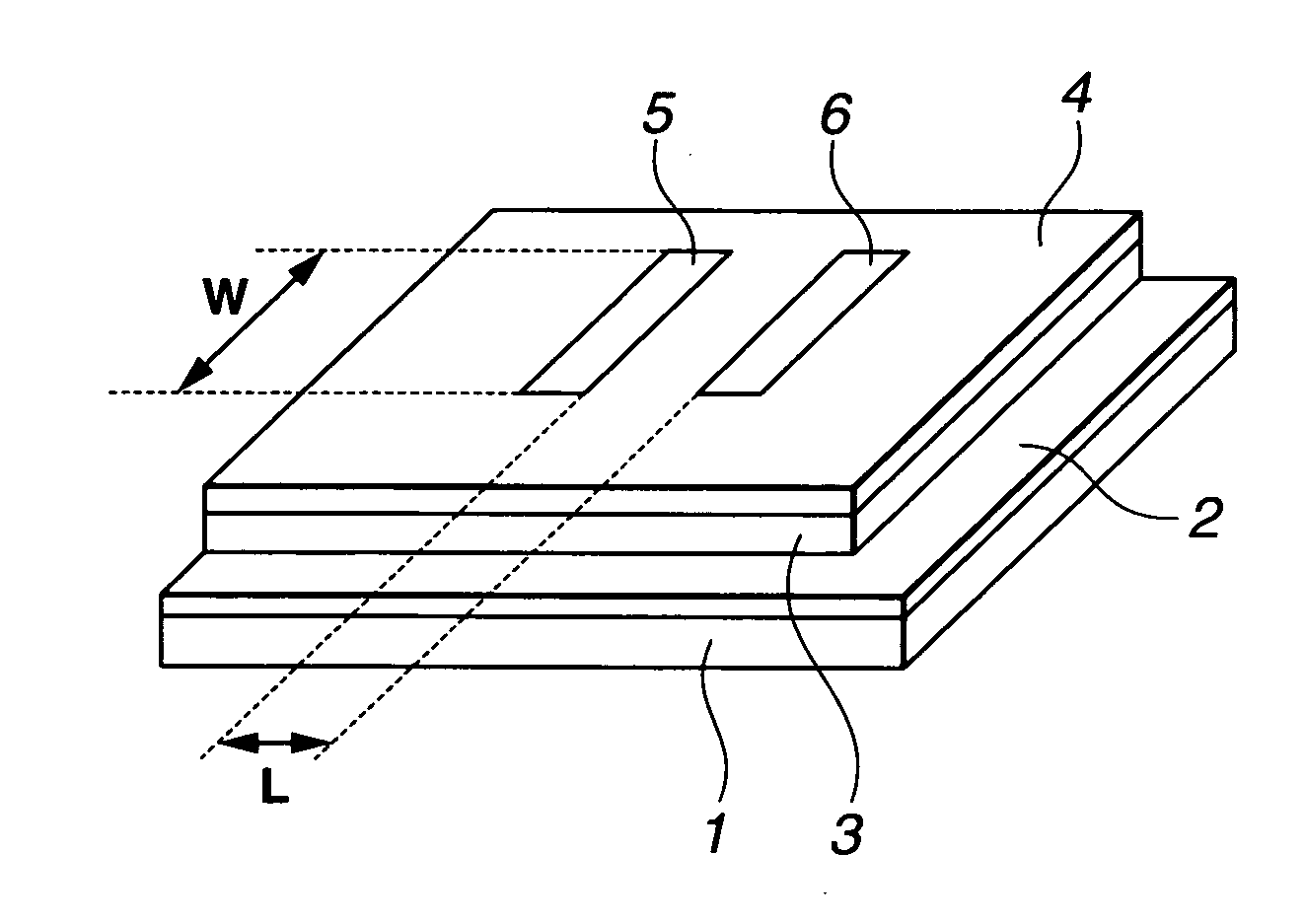

[0027] There were furnished cyanoethyl pullulan having a substitution of cyanoethyl of 85.2 mol % (CyEPL, Shin-Etsu Chemical Co., Ltd., CR-S, Mw=49,000) as an insulating layer material and poly(3-hexylthiophene) (P3HT, Aldrich, Mw=87,000) as an organic semiconductor layer material. The organic solvent in which P3HT was dissolved was chloroform, in which CyEPL was insoluble. A TFT was fabricated using these materials and evaluated as follows.

[0028] On a glass (SiO2) substrate, a gate electrode was formed by depositing Ti to a thickness of 5 nm and then Au to a thickness of 20 nm, using an RF sputtering technique at room temperature and a back pressure of 10−4 Pa.

[0029] An insulating layer was then formed on the gate electrode by dissolving 15 wt % CyEPL as the insulating layer material in N-methyl-2-pyrrolidone, passing the solution through a 0.2-micron membrane filter, spin coating the solution, and drying at 100° C. for one hour.

[0030] A semiconductor layer of 50 nm thick was th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| dielectric constant | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com