Conversion pad with moisture barrier

a technology of conversion pads and moisture barriers, which is applied in the field of conversion pads for sanding tools, can solve the problems of warping of many materials used for conversion pads, inconsistent or uneven sanding of work surfaces, and interference with sanding operations, etc., and achieves improved warp resistance, improved sanding characteristics, and easy manufacturing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example

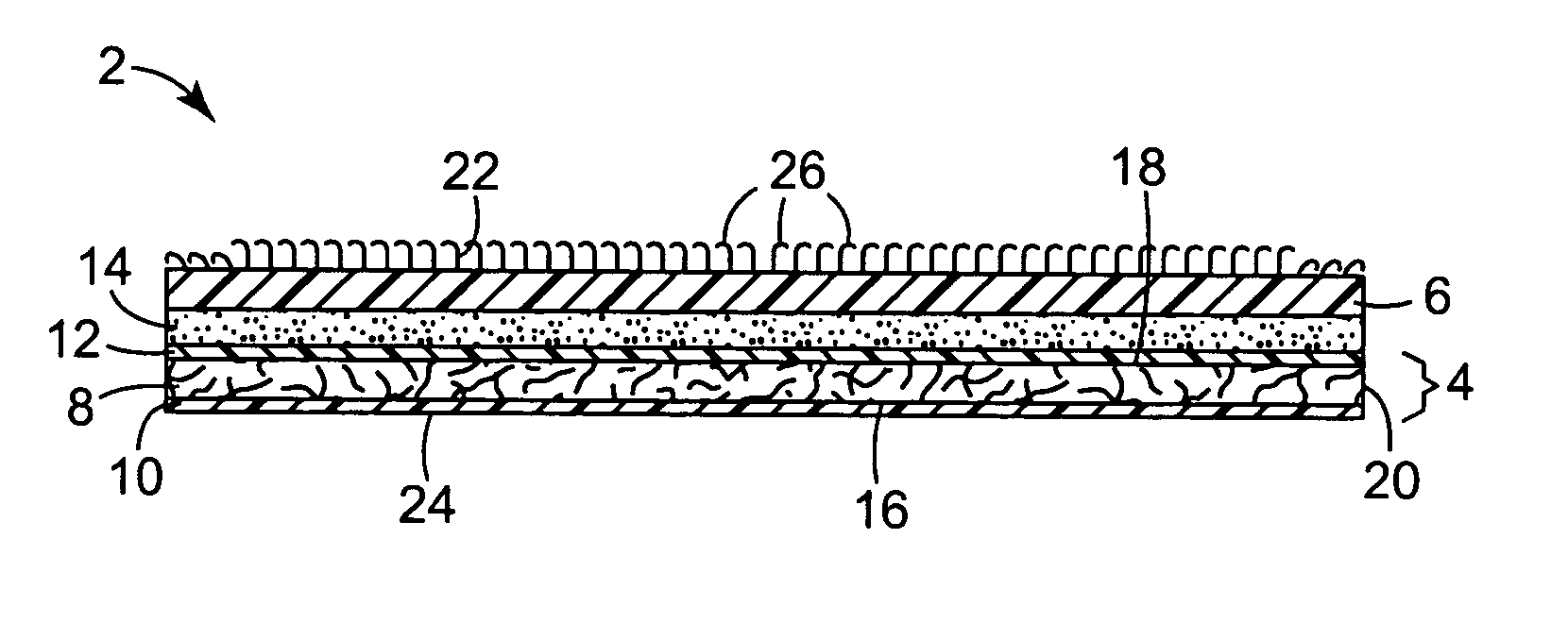

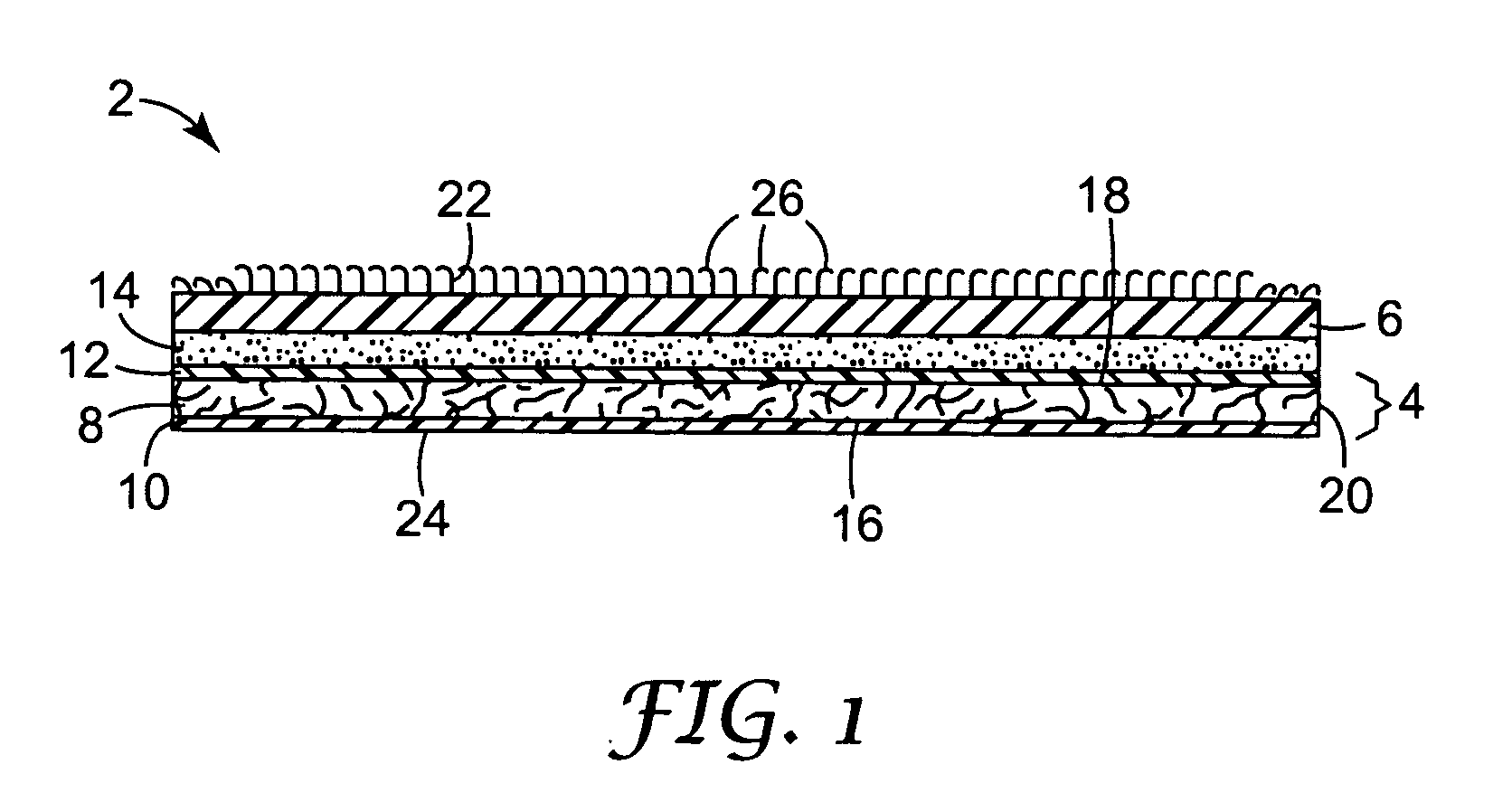

[0025] A conversion pad having the construction shown in FIG. 1 was prepared as follows. A 30 mil thick vulcanized fiber backing available from 3M Company, St. Paul, Minn. was coated on both major surfaces with PU-40 polyurethane available from Illbruck, Inc., Minneapolis, Minn., thereby creating barrier layers that protected the backing from water and moisture. The coated backing was then affixed to an attachment member having a plurality of J style hooks using 3M Company hot melt adhesive HM 115-50, a heat resistant nylon hot melt adhesive.

[0026] The warping characteristics of the conversion pad were evaluated by storing it together with a similar conversion pad that did not include the protective polyurethane coating layers for the same amount of time and under the same temperature and humidity conditions. The conversion pad of the invention was found to undergo significantly less warping than the conversion pad that did not include the protective polyurethane coating when expos...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com