Frozen aerated product in a container and a method for manufacturing such

a technology of aerated products and containers, which is applied in the directions of rigid containers, pliable tubular containers, transportation and packaging, etc., can solve the problems of high viscosity, no commercially available aerosol forms of aerated products, and high cost, so as to reduce the number of process stations required, reduce the cost, and facilitate the effect of handling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

[0066]

FormulationSkimmed Milk Powder10.00Coconut Oil05.00Dextrose16.70Low Fructose Corn syrup10.30Sucrose01.20Monoglyceride Emulsifier00.70Acetic Acid Esters00.40LBG00.20Vanilla Flavour00.16Water55.34

(Freezing Point Depressant Solids 30.9)

(n (g mol−1) 223)

[0067] All concentrations are % (w / w).

[0068] Specialist materials were as follows: [0069] LBG was Viscogum FA supplied by Degussa Texturant Systems, France. [0070] Monoglyceride emulsifier was ADMUL MG 40-04 supplied by Quest International, Bromborough Port, UK. [0071] Acetic acid ester of monoglyceride was Grinsted ACETEM 50-00 A supplied by Danisco Cultor, Wellingborough, UK. [0072] Low Fructose Corn Syrup was C*TruSweet 017Y4, had a moisture level of 22%, a DE of 63 and was supplied by Cerester, Manchester, UK.

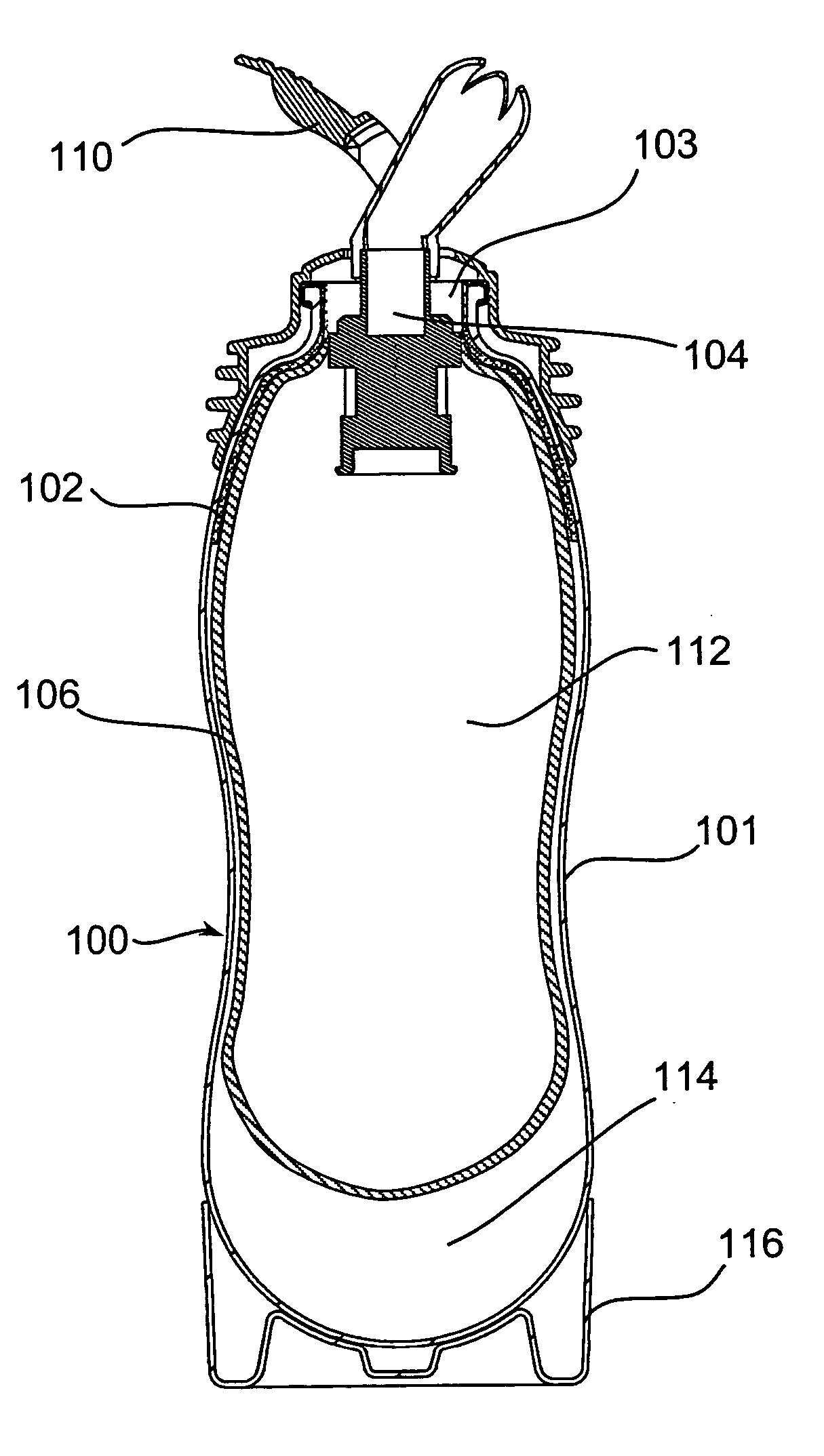

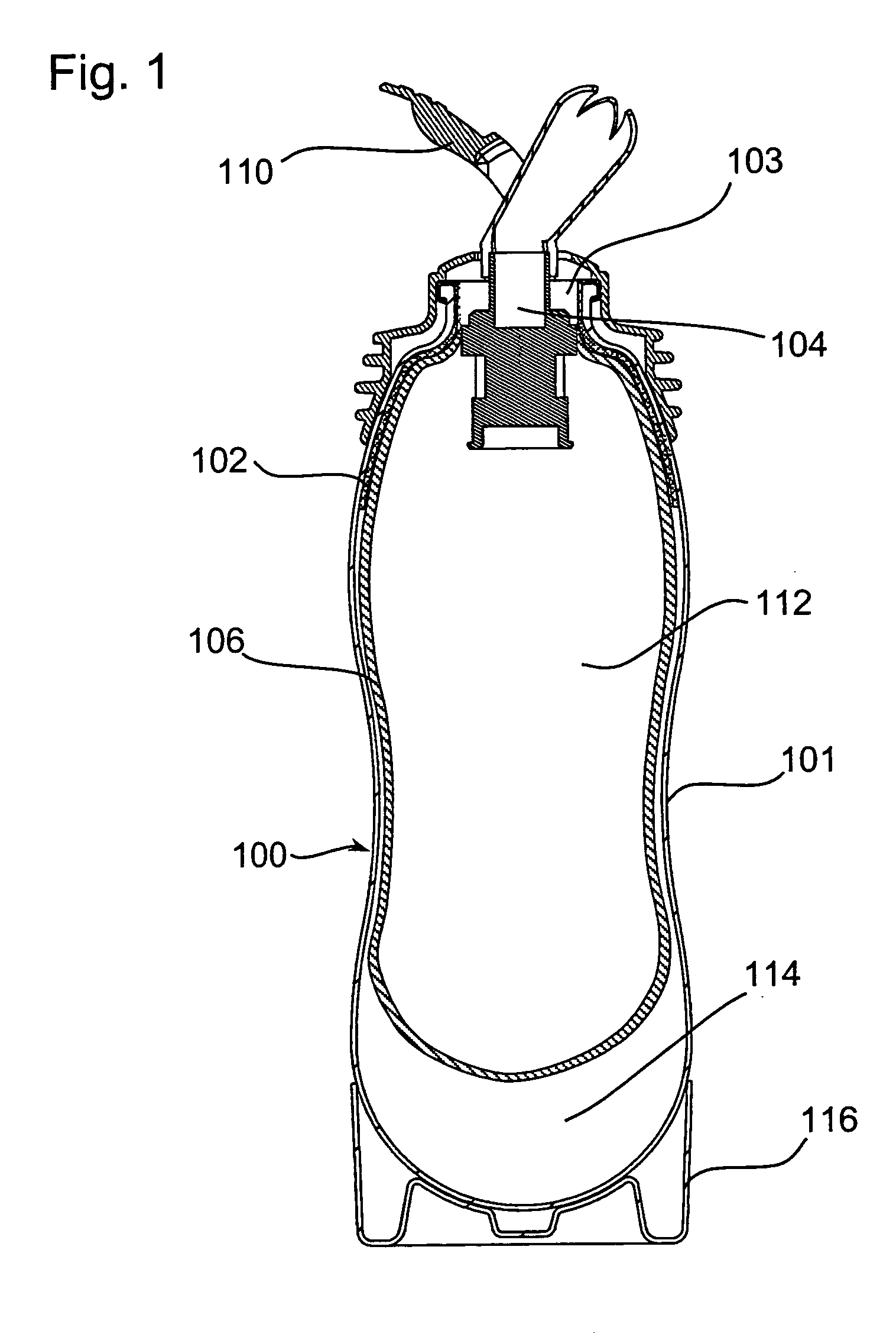

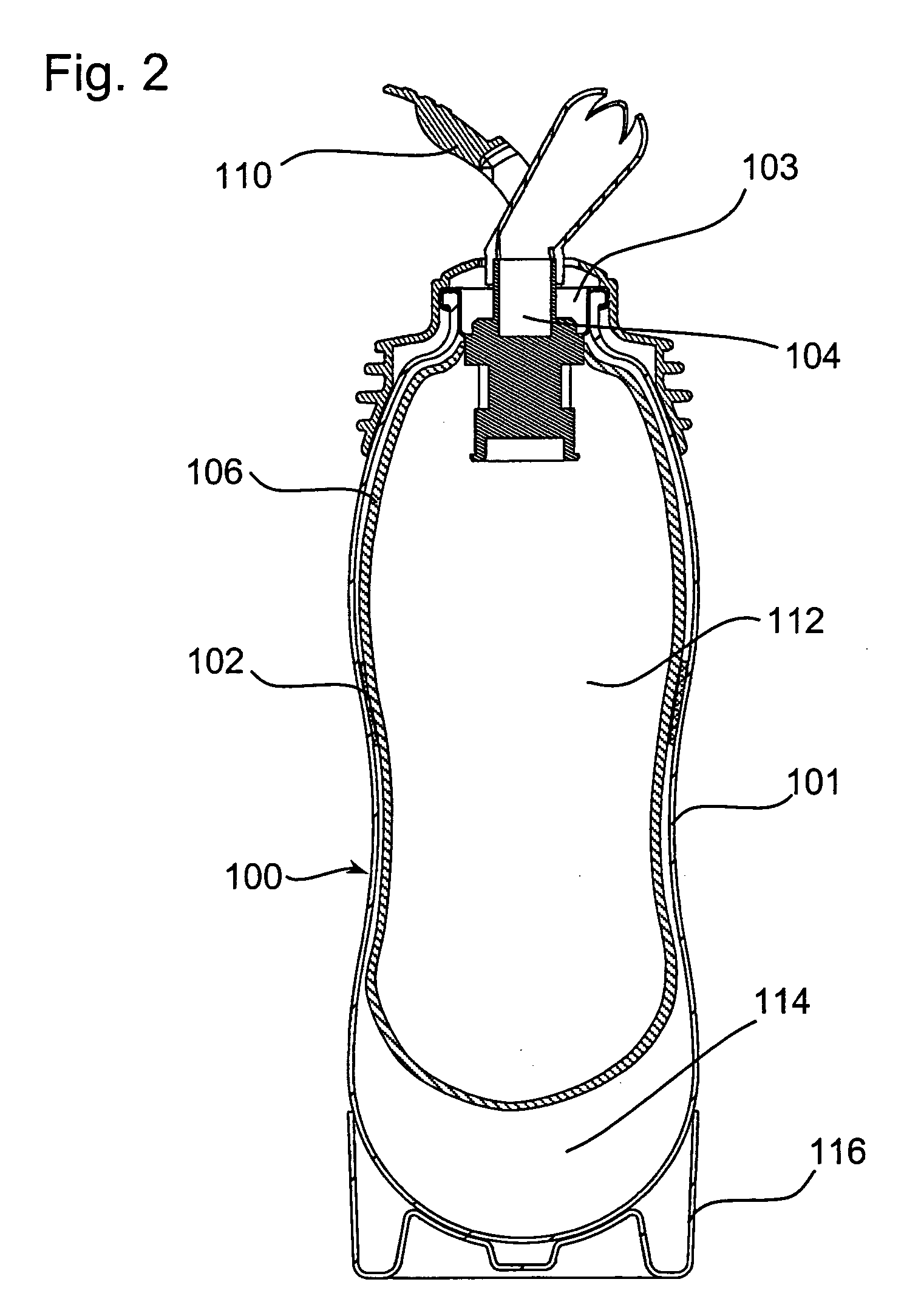

Packaging

[0073] Extrusion blow-moulded PET (Laserplus grade, Dupont) bottles were provided by Polimoon Fibrenyle, Ellough, Beccles, UK. These bottles had a brim-fill capacity of 500 ml and a burst gauge pressure of 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com