Laser process to produce drug delivery channel in metal stents

a metal stent and laser technology, applied in metal working devices, other domestic objects, manufacturing tools, etc., can solve the problems of reoccurring constrictions or blockages, exacerbate the occurrence of restenosis or thrombosis, and affect areas of the body not needing treatmen

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

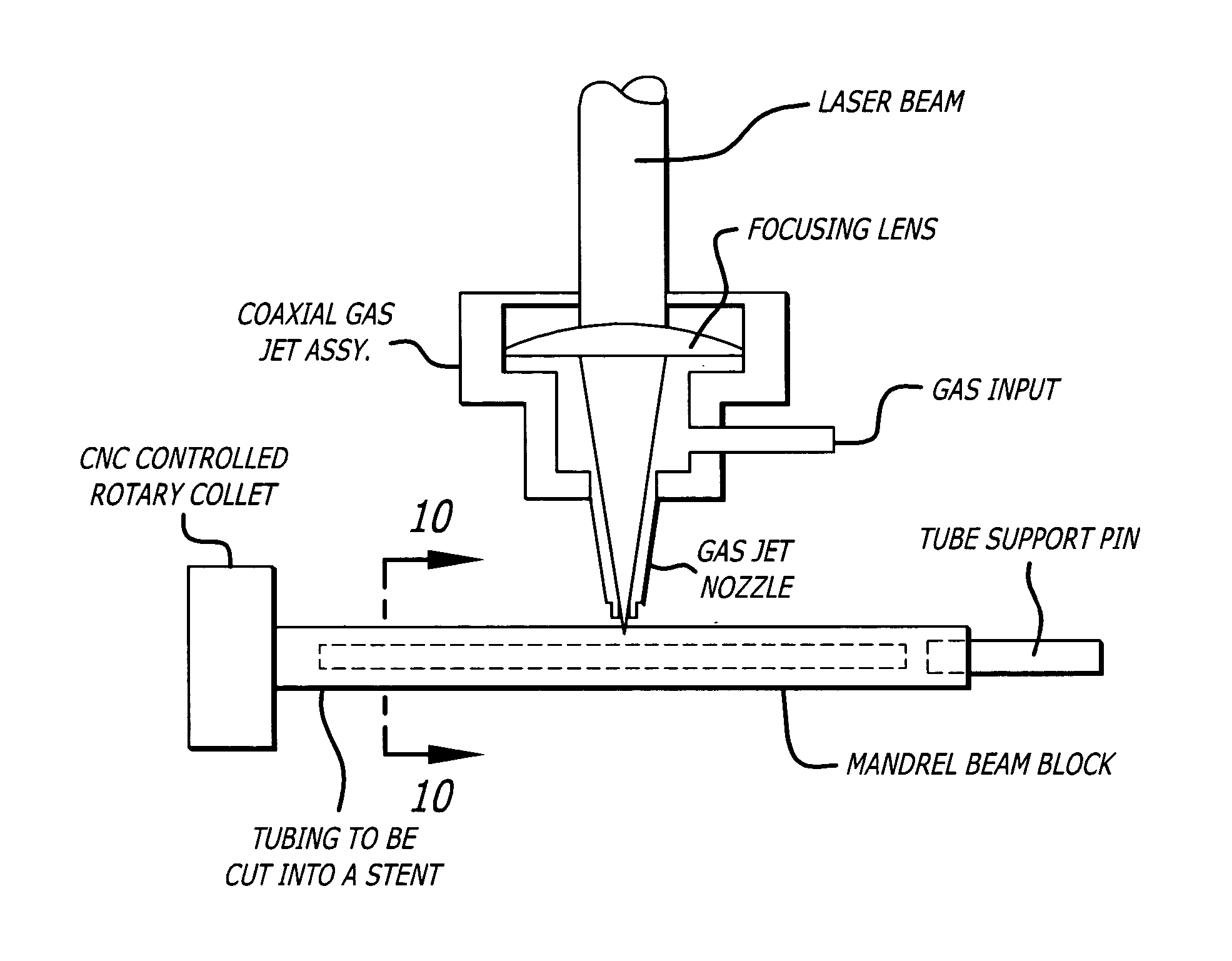

Method used

Image

Examples

Embodiment Construction

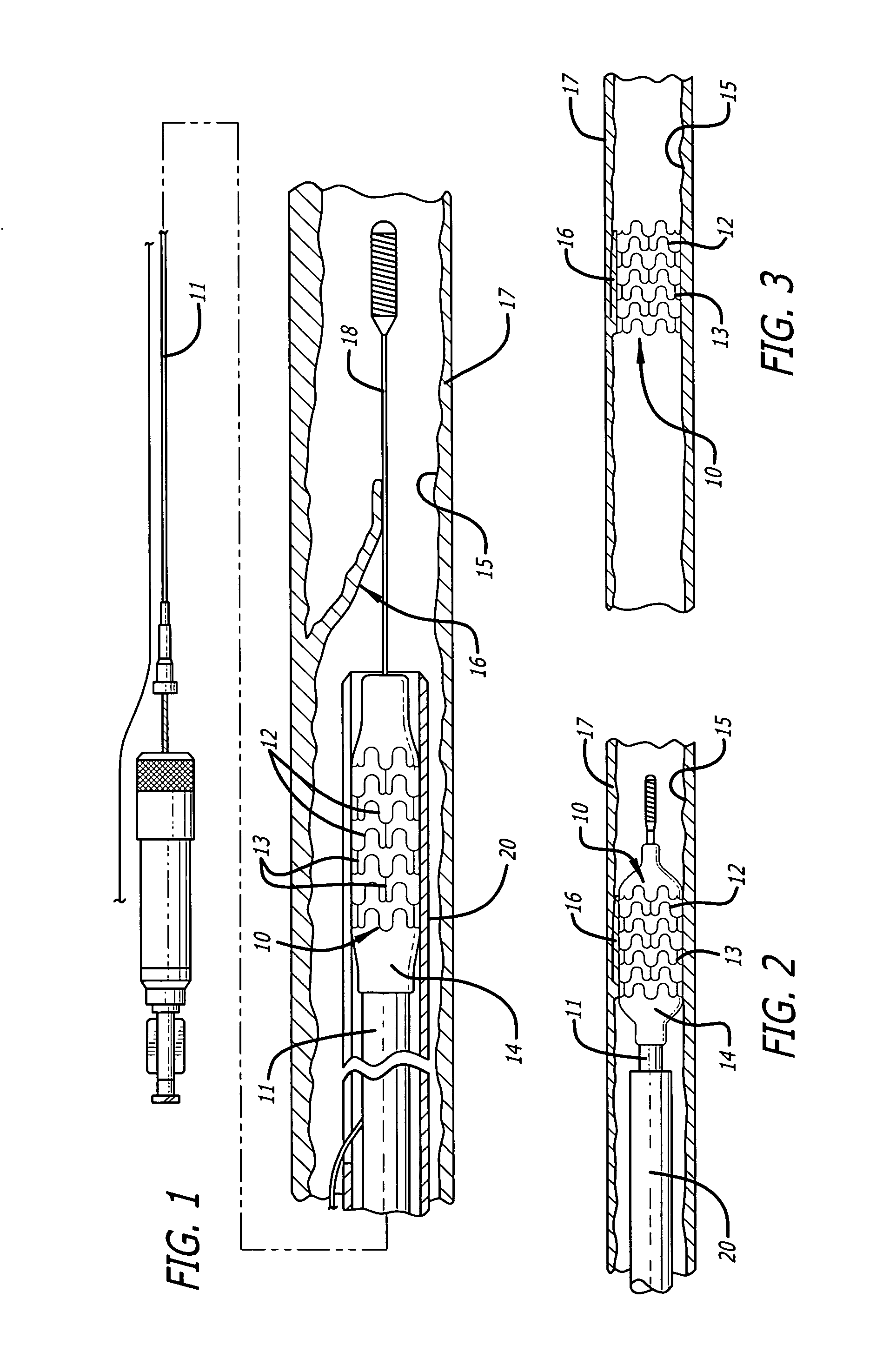

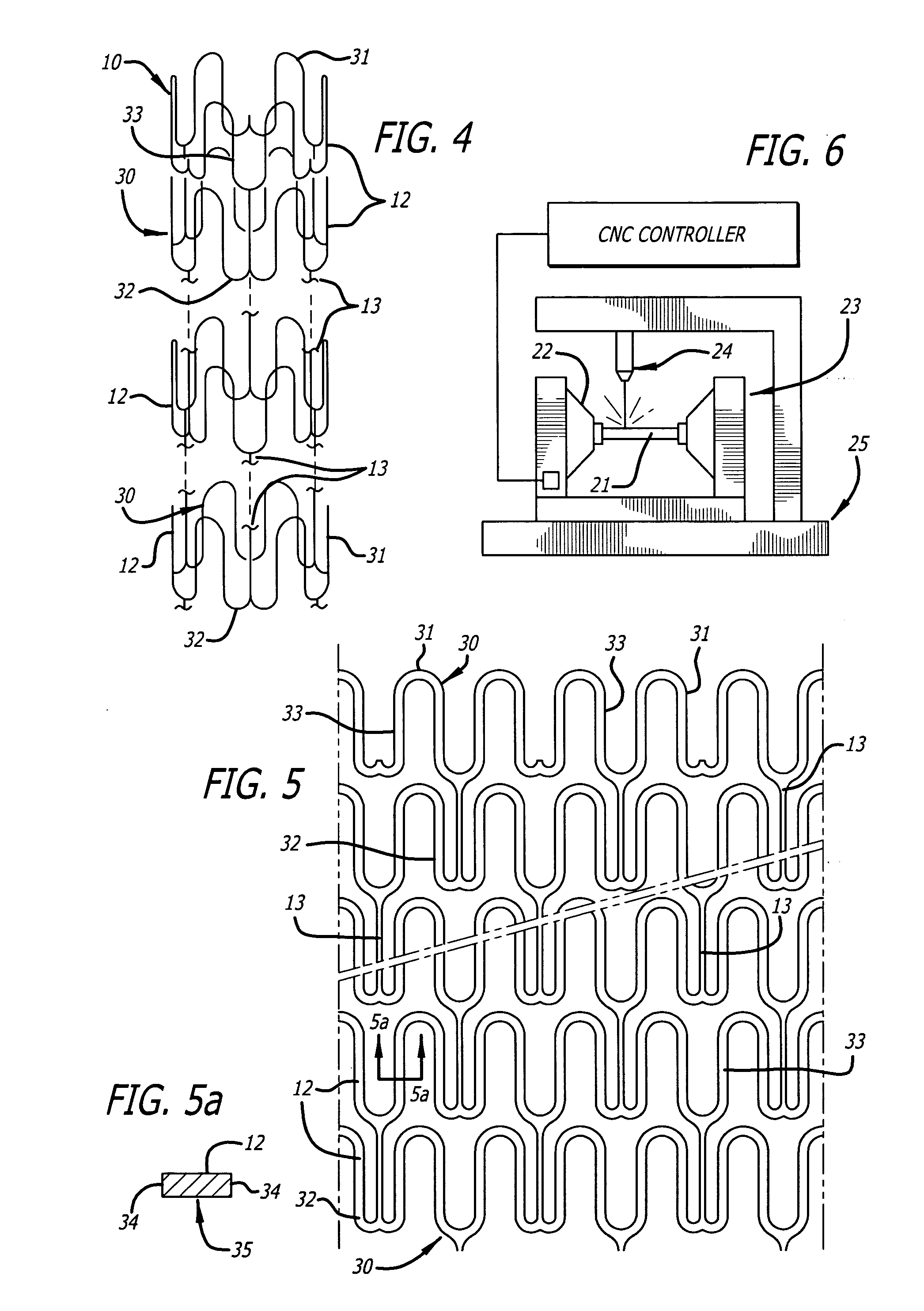

[0039] To assist in understanding the present invention, it is useful to first describe a typical stent, the manner in which it is mounted on a catheter for implantation in a vessel lumen, and a procedure typically used for carrying out the implantation. While one particular stent design is used for illustration, those skilled in the art will understand that the structure and method of the present invention may be applied to any stent design capable of having reservoirs, which may be filled with a therapeutic substance, formed in an outer surface of the stent.

[0040] Referring now to the drawings, and particularly FIG. 1 thereof, there is shown a stent 10 which is mounted onto a delivery catheter 11. The stent 10 is a high precision patterned tubular device. The stent 10 typically comprises a plurality of radially expanded cylindrical elements 12 disposed generally coaxially and interconnected by elements 13 disposed between adjacent cylindrical elements. The delivery catheter 11 ha...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wavelength | aaaaa | aaaaa |

| Wavelength | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com