Chip-type electronic component and chip resistor

a technology of electronic components and resistors, applied in the manufacture of resistors, resistor details, resistive material coatings, etc., can solve the problems of difficult to recognize the application state of conductive paste, difficult to check the application state of conductive paste, difficult to check the appearance, etc., to achieve the effect of improving the mass production feasibility and speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

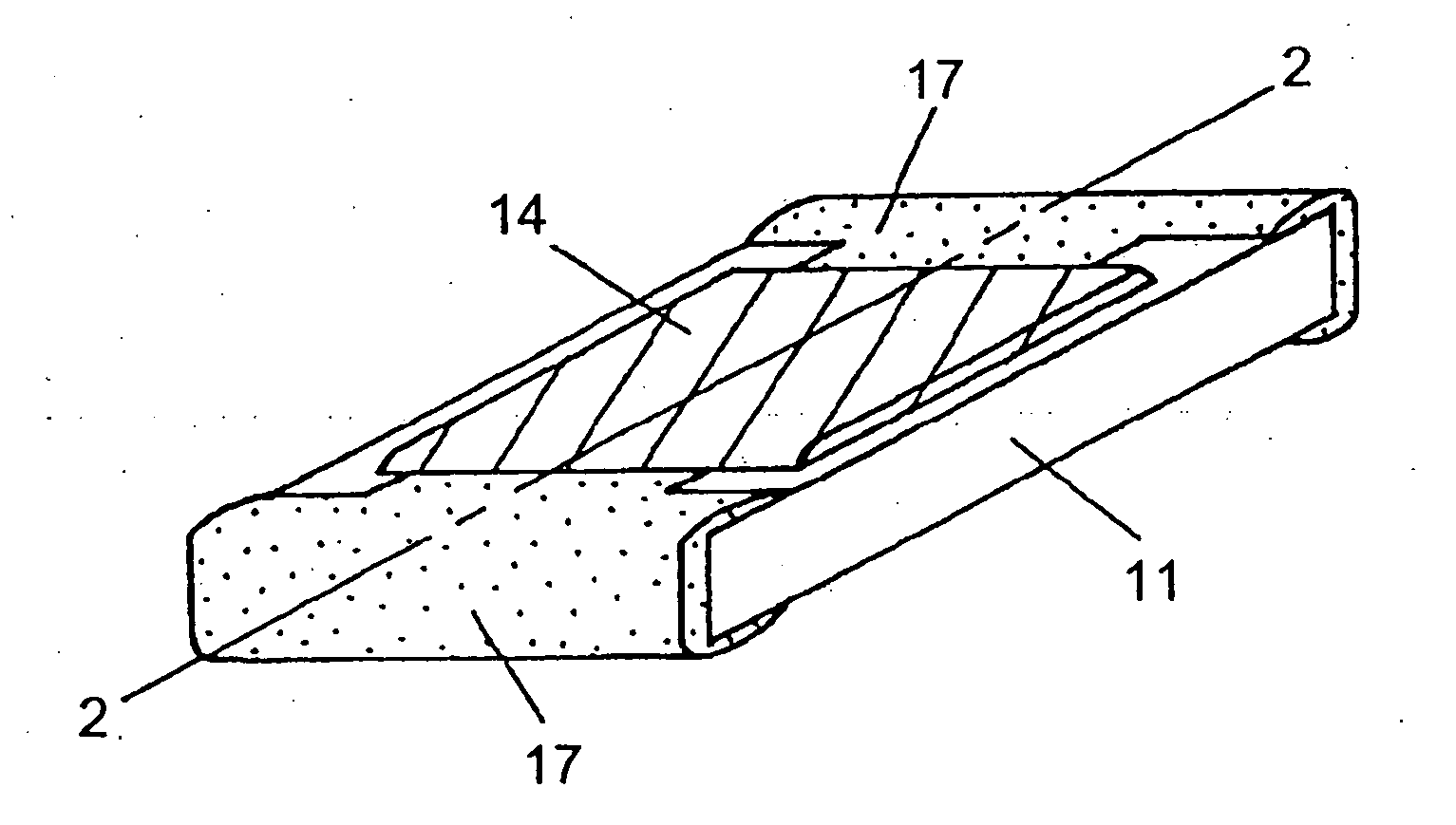

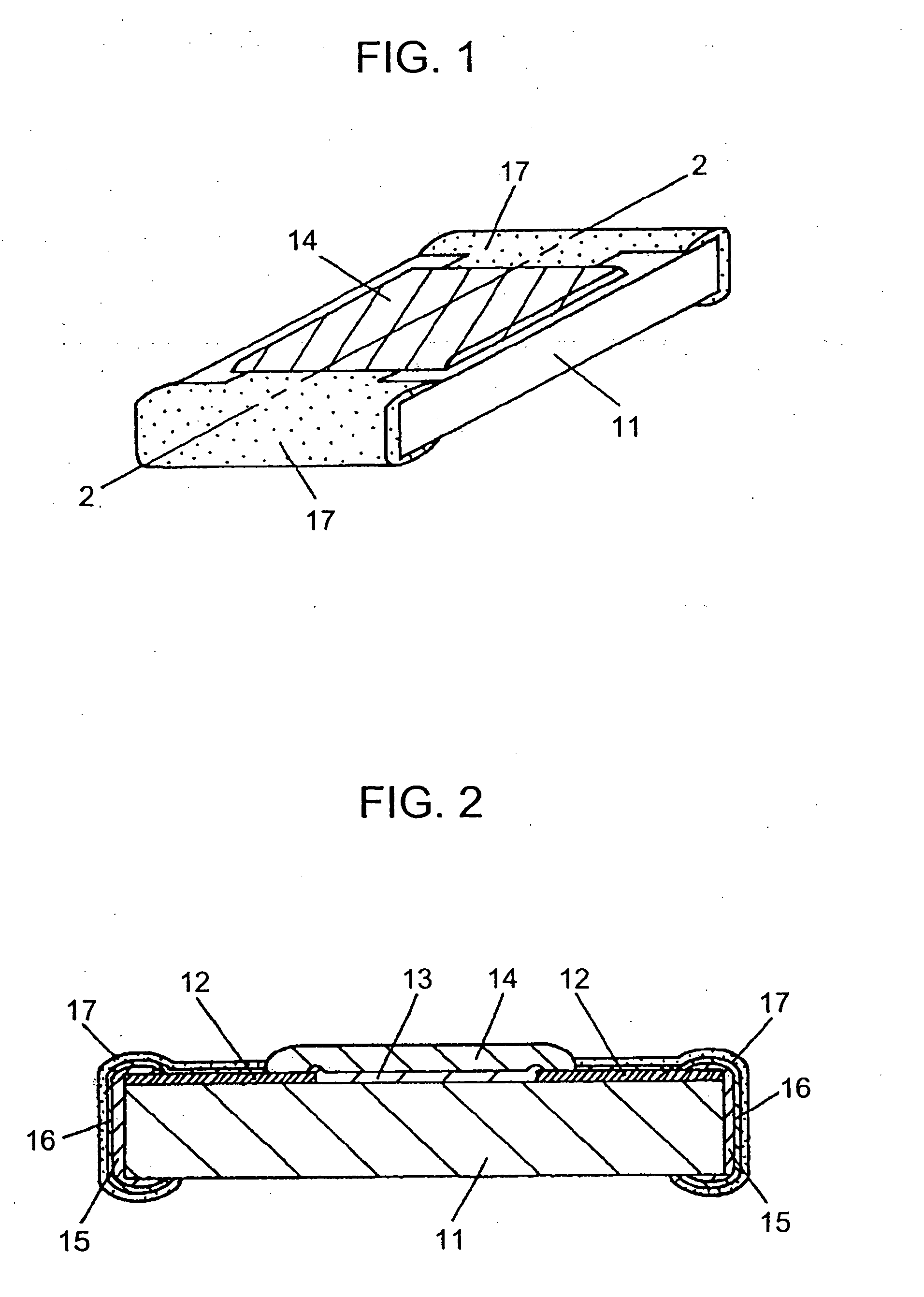

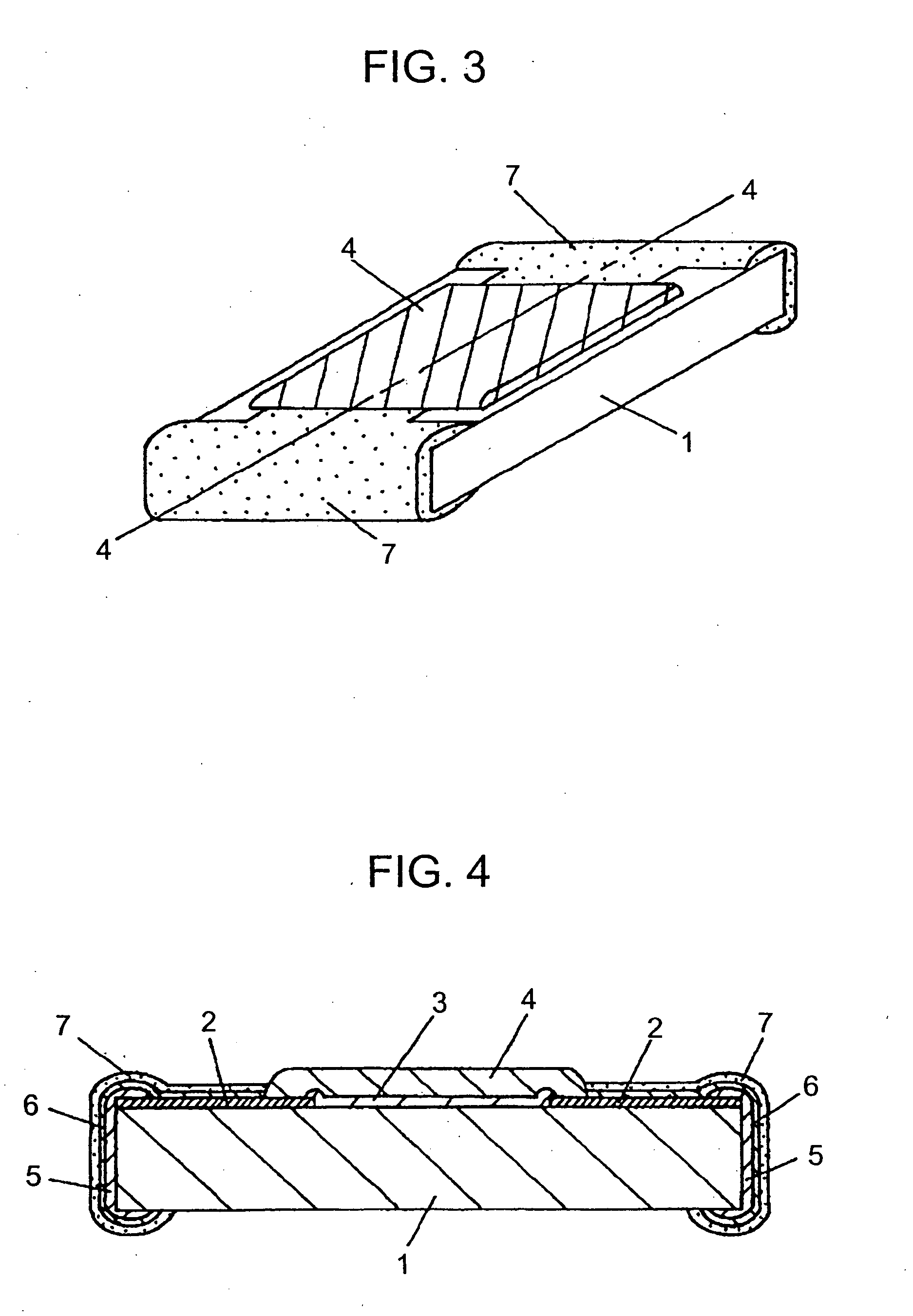

[0040] A structure of a chip resistor in Example 1 of the present invention has the same structure as these of the chip resistor shown in FIG. 1 and FIG. 2. As a resin for the conductive paste for forming side electrodes, bisphenol-A type epoxy resin, a thermosetting resin, and imidazole hardener are used. And spherical silver powder of 0.06 μm in average particle diameter is mixed with the resin at an amount of 85% as spherical conductive particles, and furnace black is further mixed at an amount of 2% as carbon powder.

example 2

[0041] A structure of the chip resistor in Example 2 of the present invention has the same structure as the chip resistor in one embodiment of the present invention shown in FIG. 1 and FIG. 2. As the resin for conductive paste for forming side electrodes, bisphenol-F type epoxy resin, a thermosetting resin, and amine hardener are used. And spherical nickel powder of 2.5 μm in average particle diameter is mixed with the resin at an amount of 90% as spherical conductive particles, and furnace black is further mixed at an amount of 1% as carbon powder.

example 3

[0042] A structure of the chip resistor in Example 3 of the present invention has the same structure as the chip resistor in one embodiment of the present invention shown in FIG. 1 and FIG. 2. As the resin for conductive paste for forming side electrodes, bisphenol-A type epoxy resin, a thermosetting resin, and imidazole hardener are used. And spherical tungsten powder of 10 μm in average particle diameter is mixed with the resin at an amount of 80% as spherical conductive particles, and furnace black is further mixed at an amount of 3% as carbon powder.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com