Resorbable structure for treating and healing of tissue defects

a tissue defect and resorbable technology, applied in the field of tissue defect resorbable structure, can solve the problems of large molecular weight degradation, and achieve the effects of rapid resorbing, high strength, and easy penetration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

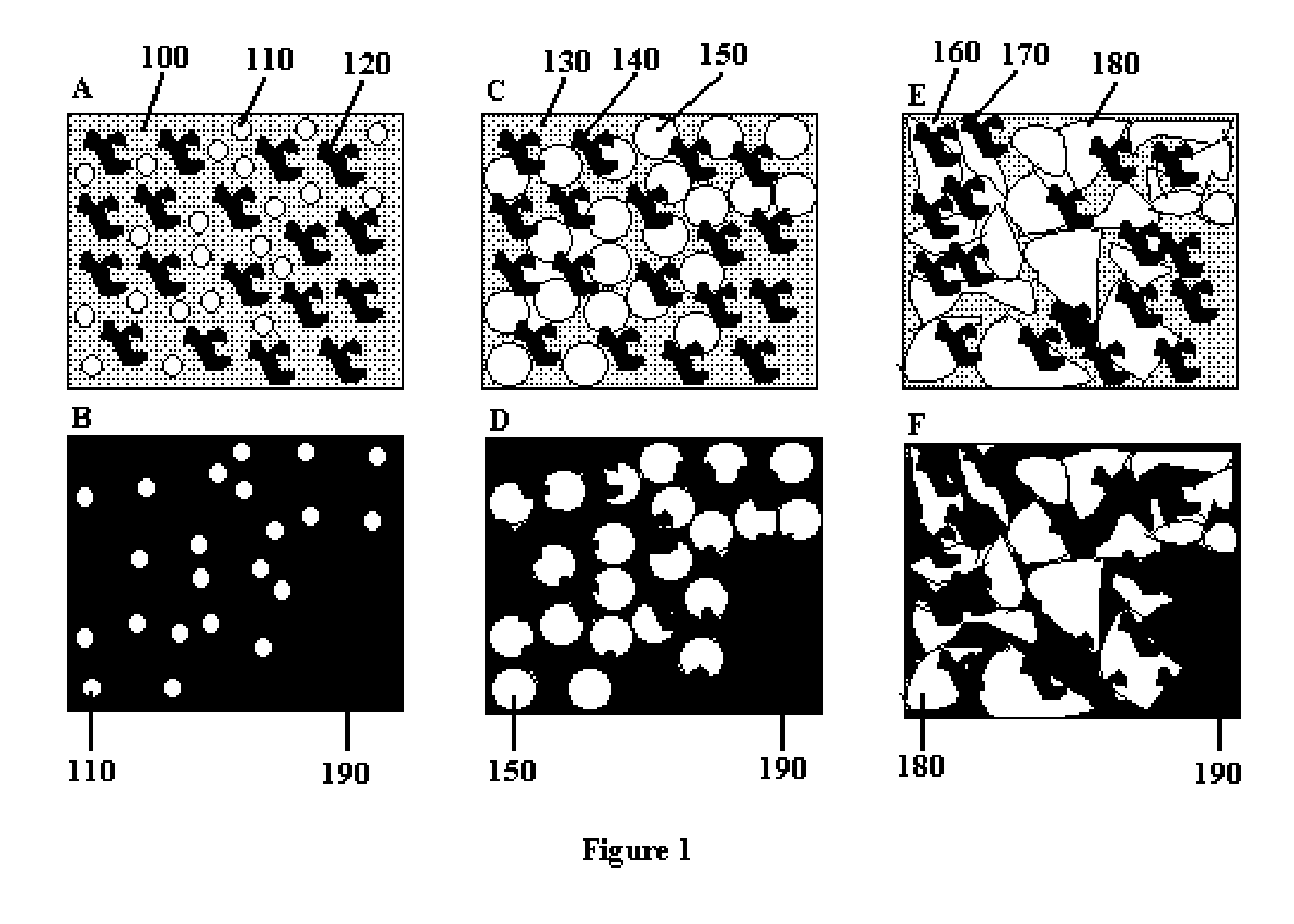

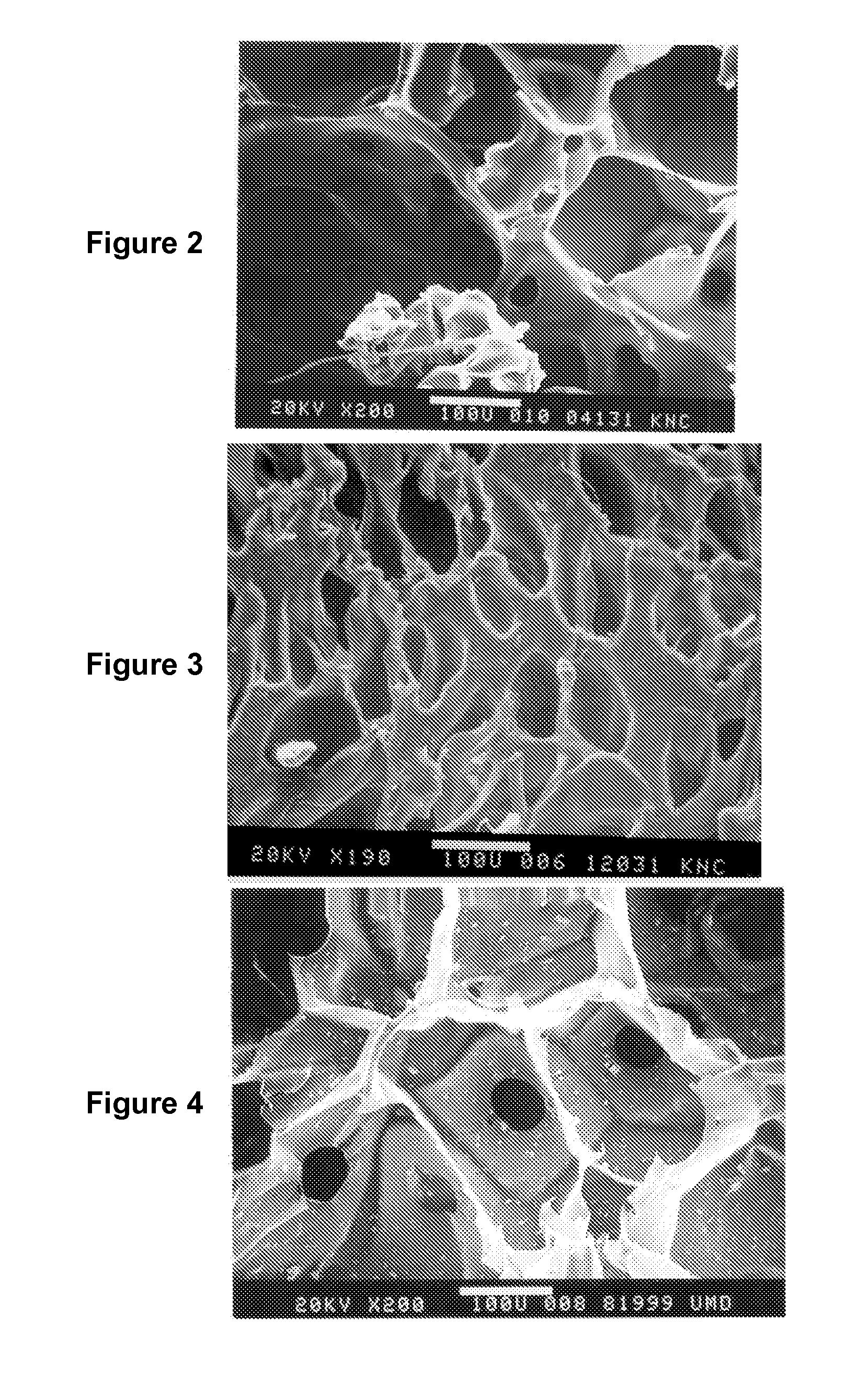

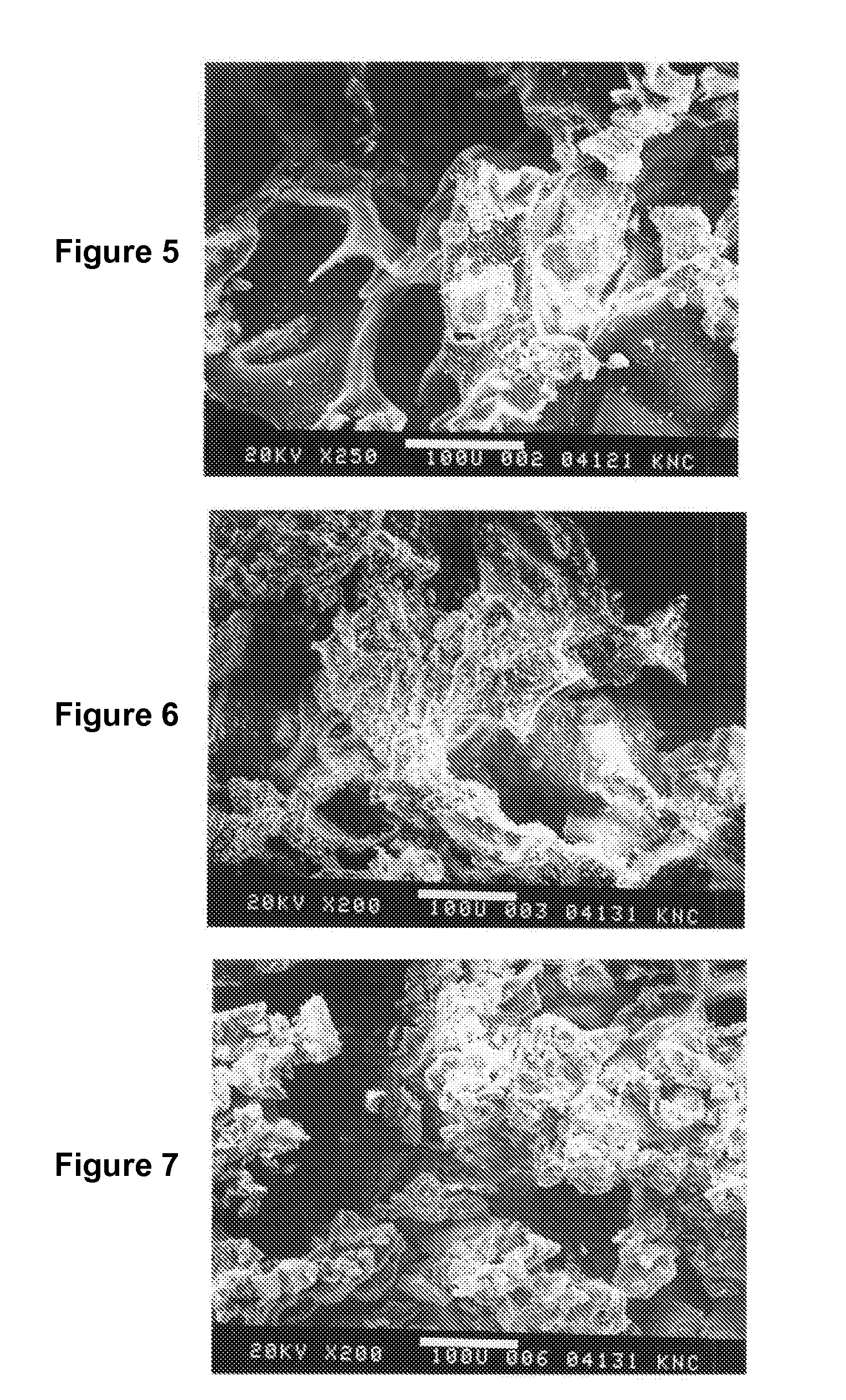

Embodiment Construction

[0056] An ideal tissue repair / treatment / prosthetic device should possess various of the following properties: (1) it should be chemically biocompatable; (2) it should be partially if not completely resorbable so that the patient's own tissue ultimately replaces at least a portion of the device; (3) it should be porous to allow the infiltration of cells over time; (4) the porosity should provide it with a high surface area to mass ratio for cell attachment and delivery of therapeutics; (5) despite the porosity, it should provide a high degree of structural integrity in order to support, fixate, or treat surrounding tissues until the patient's own bone / tissue heals; (6) the device should have the ability to incorporate additives used to enhance the mechanical or biochemical performance of the device (e.g. strengthening agents, cells, drugs, biomolecules, other agents); and, (7) the device should be mass manufacturable to be able to provide the product at a reasonable price to the cons...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com