Semiconductor Device and method of manufacturing the same

a technology of semiconductors and semiconductors, applied in the direction of semiconductor devices, basic electric elements, electrical equipment, etc., can solve the problems of poor manufacturing yield and difficulty in and achieve the effect of shortening the manufacturing process and

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

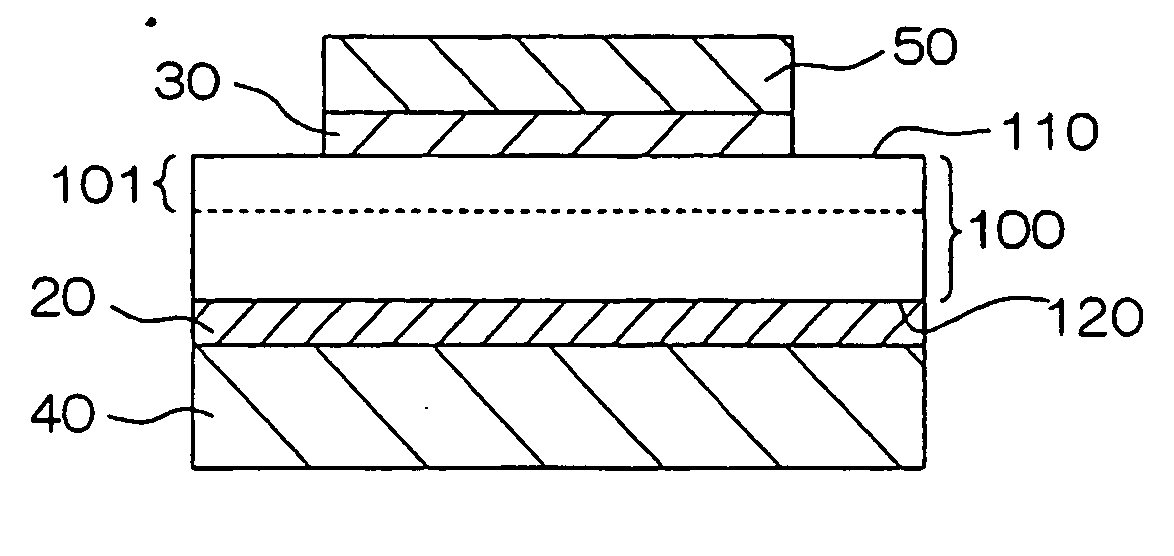

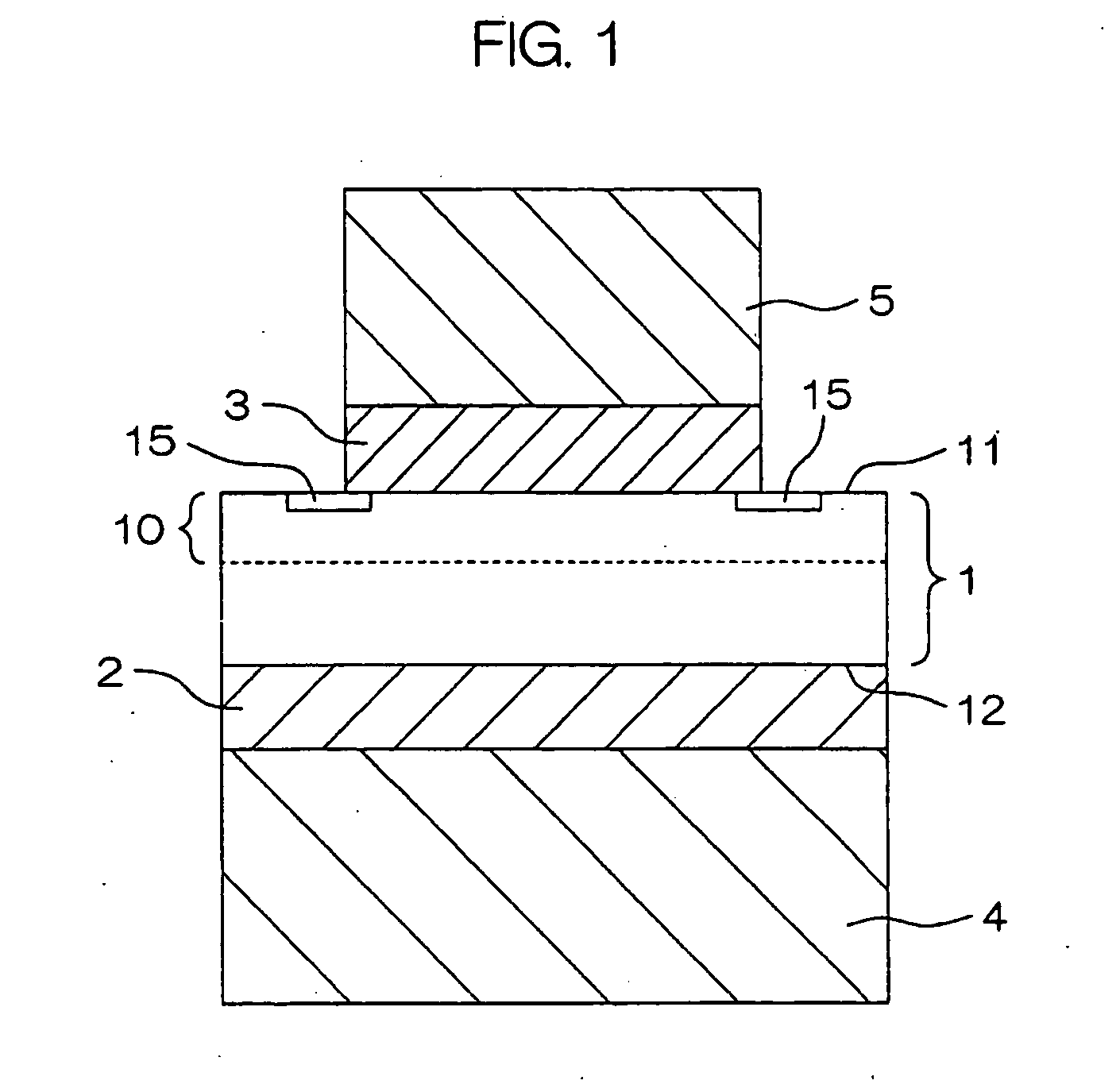

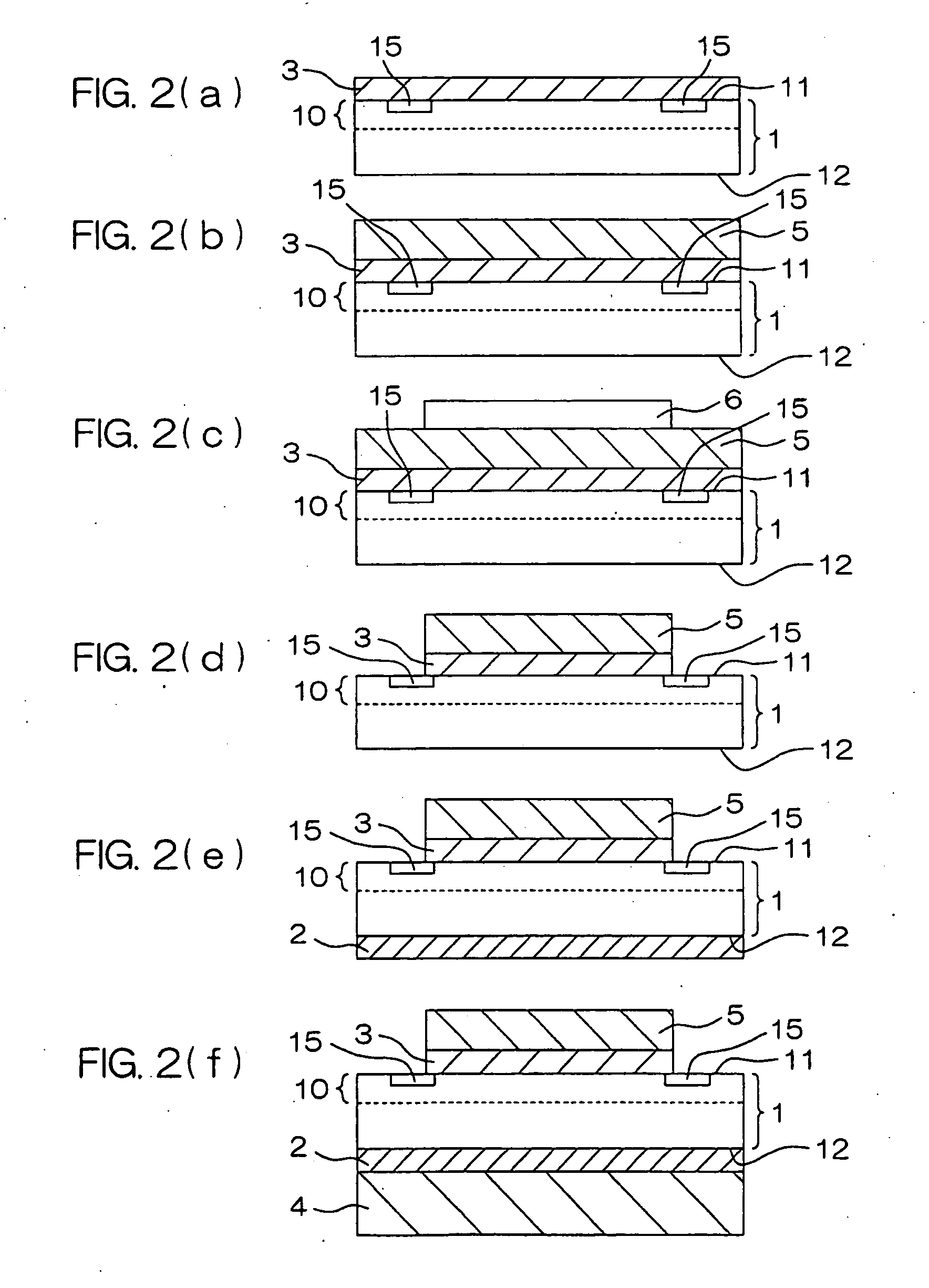

[0057]FIG. 1 is a cross-sectional view schematically showing the configuration of a semiconductor device according to an embodiment of the present invention. The semiconductor device is a Schottky barrier diode, for example. An example of a semiconductor substrate is an N-type SiC semiconductor substrate (e.g., a 4H-SiC epiwafer) 1 having a surface orientation of {0001} and having an off angle of 8°. An edge termination 15 is formed, in the SiC semiconductor substrate 1, by boron implantation and annealing at a relatively low temperature (approximately 1000° C.).

[0058] One surface of the SiC semiconductor substrate 1 is a silicon surface 11, and the other surface thereof is a carbon surface 12.

[0059] An N-type SiC semiconductor epitaxial layer 10 having a thickness of approximately 10 μm and having a carrier concentration of 4.0×1015 / cm3 to 8.0×1015 / cm3 is formed on the silicon surface 11. Consequently, the carrier concentration in the SiC semiconductor substrate 1 on the side of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperature | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com