Sulphur free composition and lubricant composition and methods thereof

a technology of sulphur free composition and lubricant composition, which is applied in the direction of lubricant composition, liquid carbonaceous fuels, fuels, etc., can solve the problems of reducing the performance of catalytic converters, adversely affecting the performance of exhaust treatment devices, and increasing the amount of greenhouse gases such as nitric oxide and/or sulphur oxides, so as to improve the performance of internal combustion engines and improve one or more performance properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

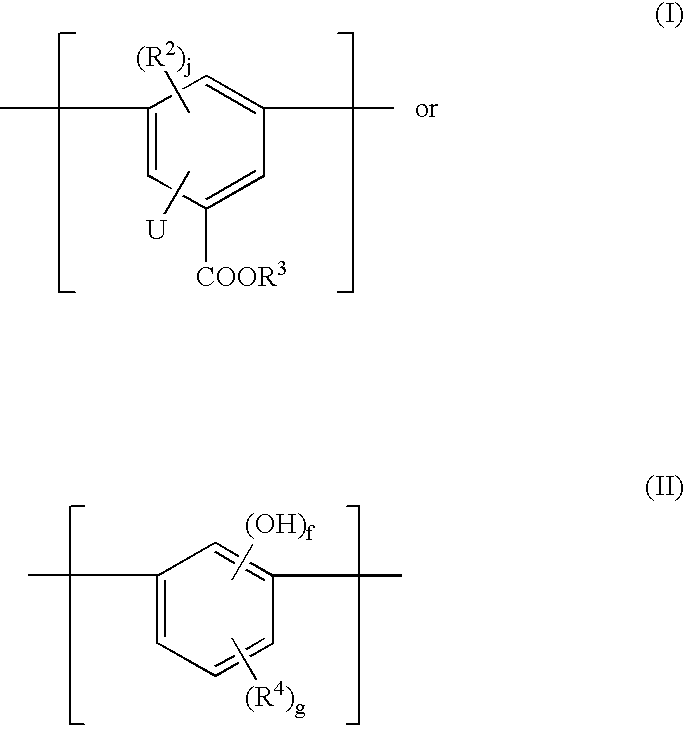

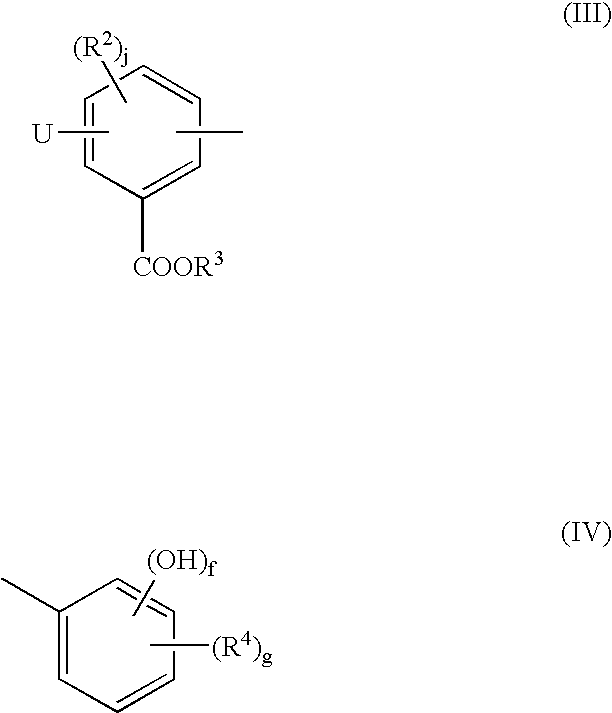

Method used

Image

Examples

example a

Preparative Example A

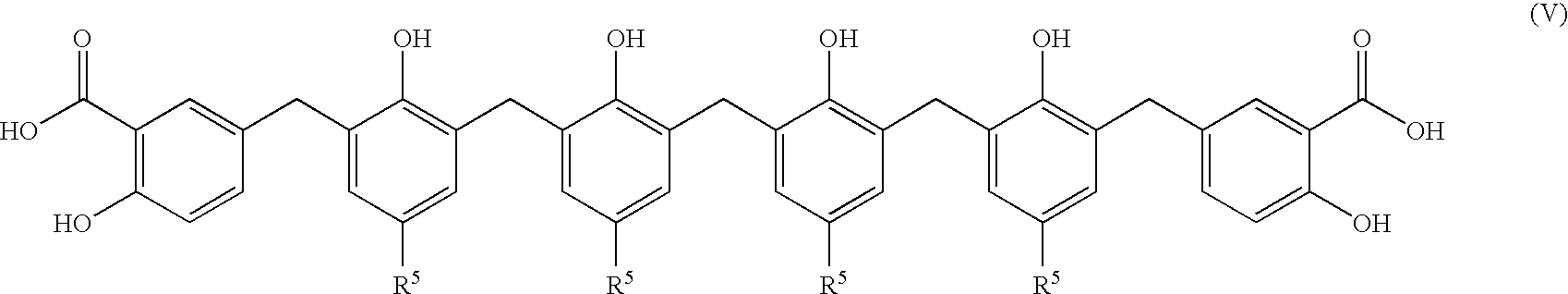

Preparation of PIB Phenol-Formaldehyde-Salicylic Acid

[0084] A 2 litre reaction flask is charged with 475 g (0.739 mole, 1 eq) polyisobutenyl phenol derived from high vinylidene polyisobutylene with a number average molecular weight of 550 (GLISSOPAL®550 commercially available from BASF) and 330 g mineral oil (SN150) and heated to 30° C. Via a pressure equalising dropping funnel, 3.4 g of 50% aqueous KOH (0.030 mole, 0.04 eq) is added all at once. The materials are heated to 75° C. followed by addition over 0.5 hour via a pressure equalising dropping funnel, 81.6 g 37% aqueous formaldehyde (formalin) (1.01 moles, 1.367 eq) followed by heating at 75° C. for 2 hours until free formaldehyde measures less than 2% (by titration). To the reaction is charged 51.6 g salicylic acid (0.374 mole, 0.51 eq) and the reaction is heated to 140° C. as quickly as possible (0.3 hour) while controlling reflux, draining water of reaction via a Dean Stark trap. The reaction is held a...

example b

Preparative Example B

Preparation of PIB Phenol-Formaldehyde-3,5-Dihydroxybenzoic Acid

[0085] The process is the same as Preparative Example A except, 415.5g of polyisobutenyl phenol derived from high vinylidene polyisobutylene with a number average molecular weight of 550 (GLISSOPAL®550 commercially available from BASF) is used, 290 g mineral oil (SN150) and 50.5 g of 3,5-dihydroxybenzoic acid is used instead of salicylic acid.

example c

Preparative Example C

Preparation of PIB Phenol-Formaldehyde-4-Hydroxybenzoic Acid

[0086] The process is the same as Preparative Example B except, 45.2 g of 4-hydroxybenzoic acid is used instead of 3,5-dihydroxybenzoic acid.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pressures | aaaaa | aaaaa |

| pressures | aaaaa | aaaaa |

| pressures | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com