Substrate processing method and substrate processing apparatus

a substrate processing and substrate technology, applied in the field of microwave plasma processing apparatuses, can solve the problems of increasing the overall size of the substrate processing apparatus b>1/b> inevitably, affecting the effect of substrate nitridation, avoiding excessive plasma energy increase, and reducing plasma energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

[0063]FIG. 5 shows the construction of a substrate processing apparatus 100 according to a first embodiment of the present invention. In FIG. 5, those parts corresponding to the parts described previously are designated by the same reference numerals and the description thereof will be omitted.

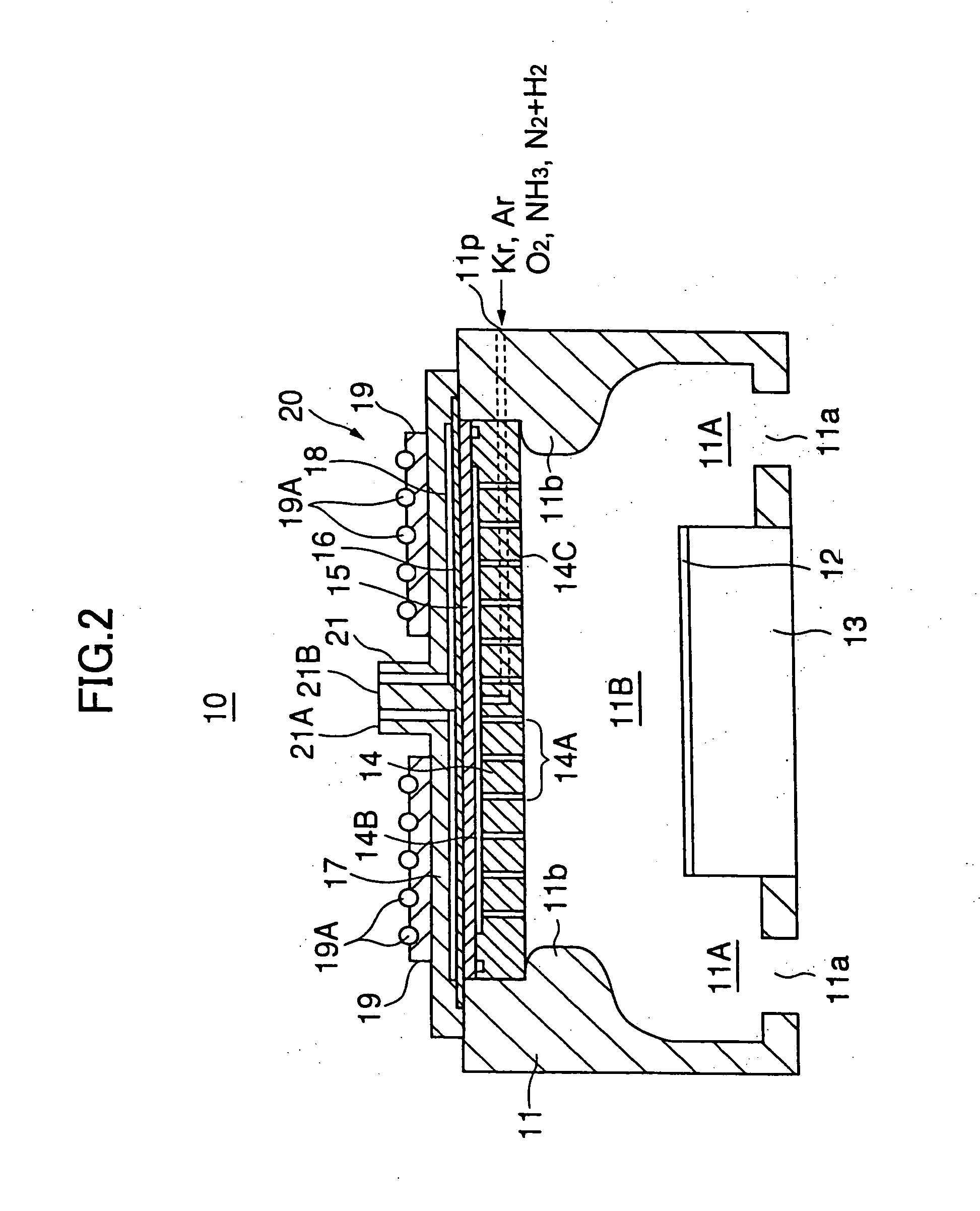

[0064] Referring to FIG. 5, the shower plate 14 is mounted on the processing vessel 11 via a seal 11s, and the cover plate 15 is mounted on the shower plate 14 via a seal 11t. Further, the radial line slot antenna 20 is mounted on the processing vessel 11 via a seal 11u.

[0065] Further, in the substrate processing apparatus 100 of FIG. 5, the interface between the emission plate 16 and the cover plate 15 is evacuated via a ring-shaped groove 11g formed at the top part of the processing vessel 11 in the region where the processing vessel makes an engagement with the emission plate and further via an evacuation port 11G communicating with the ring-shaped groove 11g. After evacuation, a He gas i...

second embodiment

[0078]FIG. 9 shows the construction of a substrate processing apparatus 200 according to a second embodiment of the present invention. In FIG. 9, those parts corresponding to the parts described previously are designated by the same reference numerals and the description thereof will be omitted.

[0079] Referring to FIG. 9, it should be noted that the shower plate 14 is removed in the present embodiment, and in place of this, there are provided a plurality of process gas inlet ports 11P on the processing vessel 11 such that the process gas inlet ports 11P are disposed with a symmetric relationship with respect to the substrate 12. As a result, therefore, the cover plate 15 constituting the dielectric window is exposed at the top part of the plasma excitation space 11B. Further, the sidewall surface of the processing vessel is covered by the quartz liner 11D for the part corresponding to the plasma excitation space 11B similarly to the previous embodiment.

[0080] According to the pres...

third embodiment

[0081]FIG. 10 shows the construction of a substrate processing apparatus 300 according to a third embodiment of the present invention. In FIG. 10, those parts corresponding to the parts described previously are designated by the same reference numerals and the description thereof will be omitted.

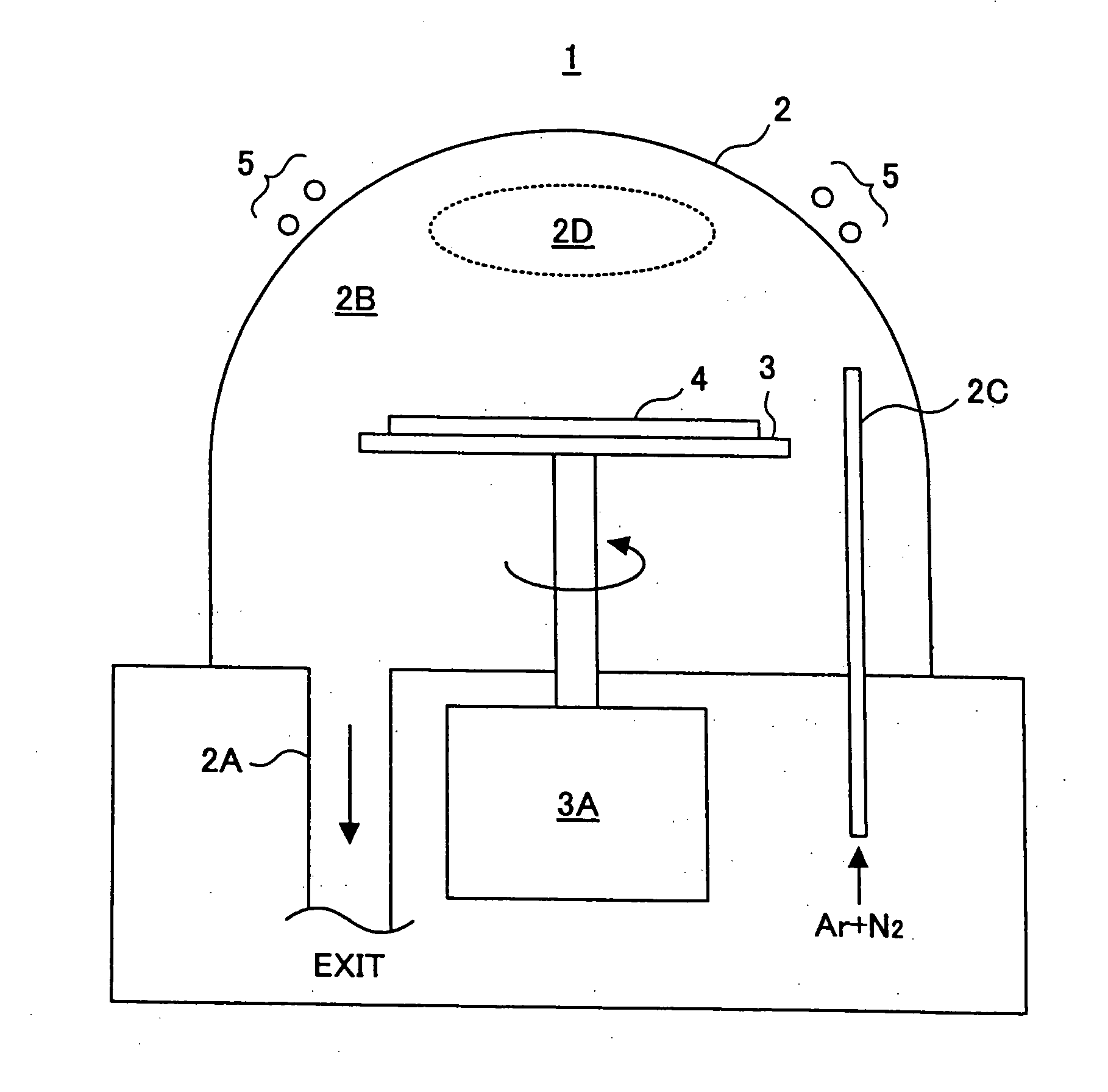

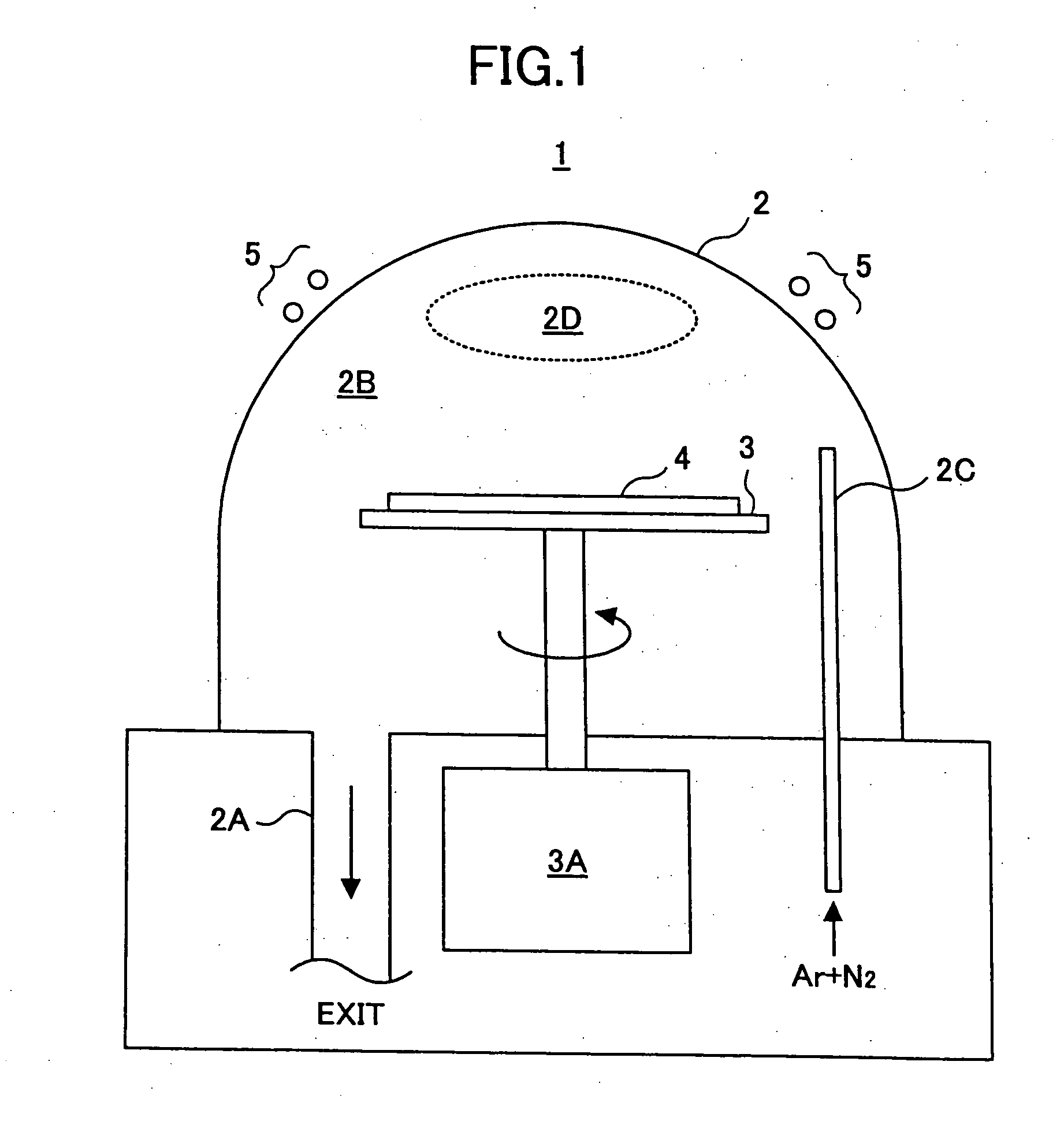

[0082] Referring to FIG. 10, the substrate processing apparatus 300 has a construction similar to the substrate processing apparatus 1 explained before with reference to FIG. 1, except that a control electrode 6 similar to the control electrode 31 is provided in the quartz vessel 2, and the space inside the quartz vessel 2 is divided by the control electrode 6 into a plasma excitation space 2B1 in which the high-density plasma 2D is excited and a process space 2B2 that includes the substrate 4 to be processed.

[0083] In the present embodiment, a He gas and an N2 gas are introduced into the plasma excitation space 2B1 via the process gas supply line 2C, and there is formed high-density plasm...

PUM

| Property | Measurement | Unit |

|---|---|---|

| gate length | aaaaa | aaaaa |

| energy | aaaaa | aaaaa |

| energy | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com