Semiconductor device and method for manufacturing same

a semiconductor device and semiconductor technology, applied in the field of semiconductor devices, can solve the problems of insufficient mechanical performance and/or plasma resistance of films having lower dielectric constants, insufficient adhesiveness, and insufficient adhesion between films, etc., to achieve the effect of effectively inhibiting the introduction of moisture, improving the reliability of semiconductor devices, and improving the integration level of semiconductor devices

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

[0060]FIGS. 9A to 9D are the cross sectional views showing the processing steps of the process for forming the semiconductor device according to the first preferred embodiment of the present invention.

[0061] In the method for manufacturing the semiconductor device according to the present embodiment, an underlying insulating film 201 is disposed on a substrate 200 having a semiconductor device formed thereon, and a SiCN film 202, which will be an etch stop film at the stage of forming an interconnect groove, is deposited via plasma CVD thereon to a thickness of 50 nm. Then, a L-Ox™ film 203 is formed by an applying method to a thickness of 300 nm, and the baking processing is carried out within N2 atmosphere at 400 degree C. for 30 minutes. Subsequently, a SiO2 film 204 is deposited to a thickness of 100 nm (FIG. 9A). The deposition process of the SiO2 film 204 is carried out by employing a source gas containing SiH4 and N2O, and the volumetric flow rates of SiH4 and N2O are set to...

second embodiment

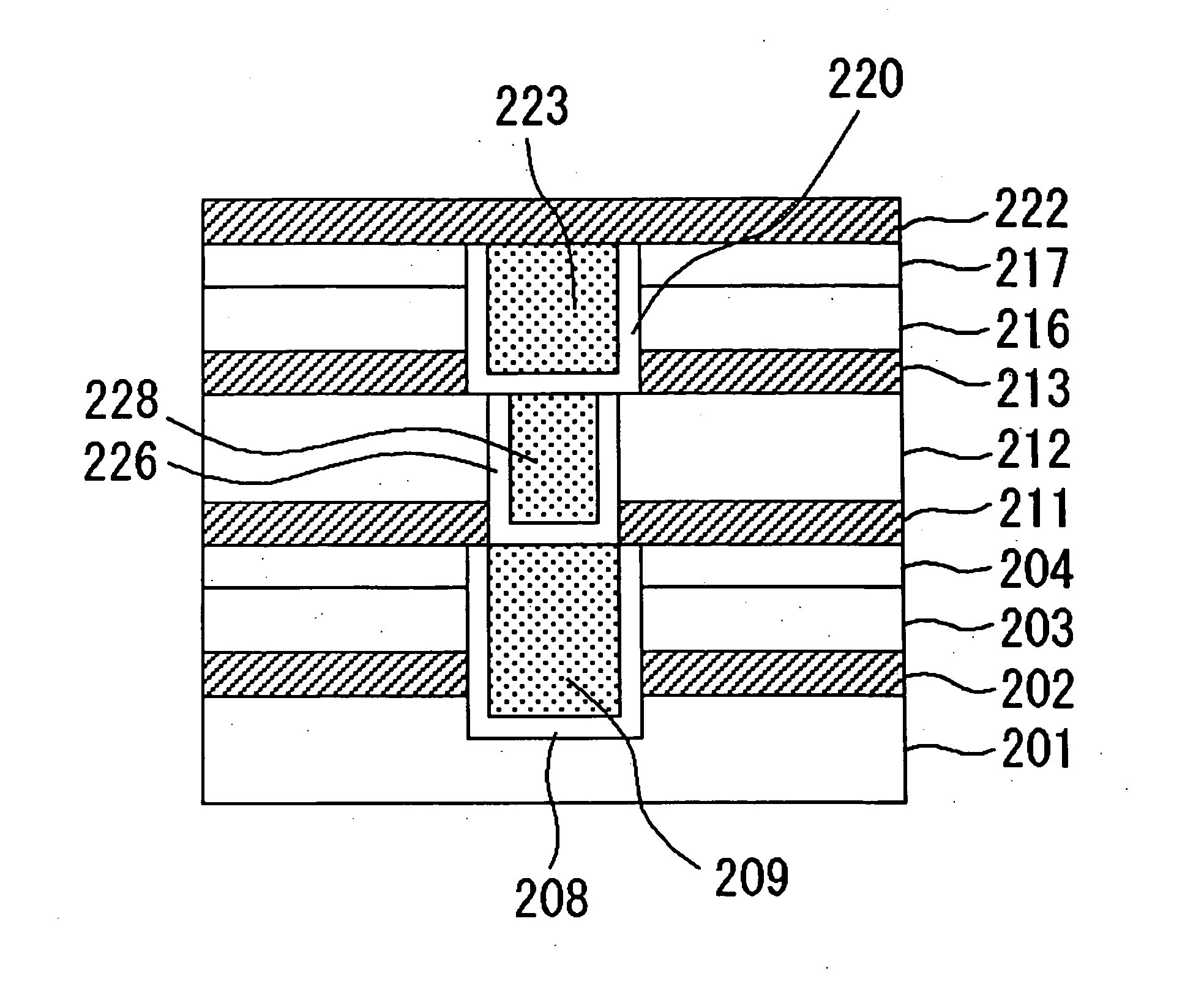

[0067] The present embodiment shows an embodiment, in which the present invention is applied to a dual-layer copper interconnect having a single damascene structure. FIG. 10 is a cross sectional view of structure of a semiconductor device according to the present embodiment. The semiconductor device according to the present embodiment has a configuration, in which a lower interconnect comprising a Cu film 209 is coupled to an upper interconnect comprising a Cu film 223 through a copper plug 228.

[0068] The lower interconnect comprising the Cu film 209 is formed in a multilayer films that include an underlying insulating film 201, a SiCN film 202, a L-Ox™ film 203 and a SiO2 film 204. Side surfaces and a bottom surface of the Cu film 209 are covered by Ta / TaN films 208.

[0069] The copper plug 228 is provided in a hole formed in multilayer films comprising a SiCN film 211 and a SiO2 film 212, and side surfaces and a bottom surface thereof are covered by Ta / TaN films 226.

[0070] The up...

example 1

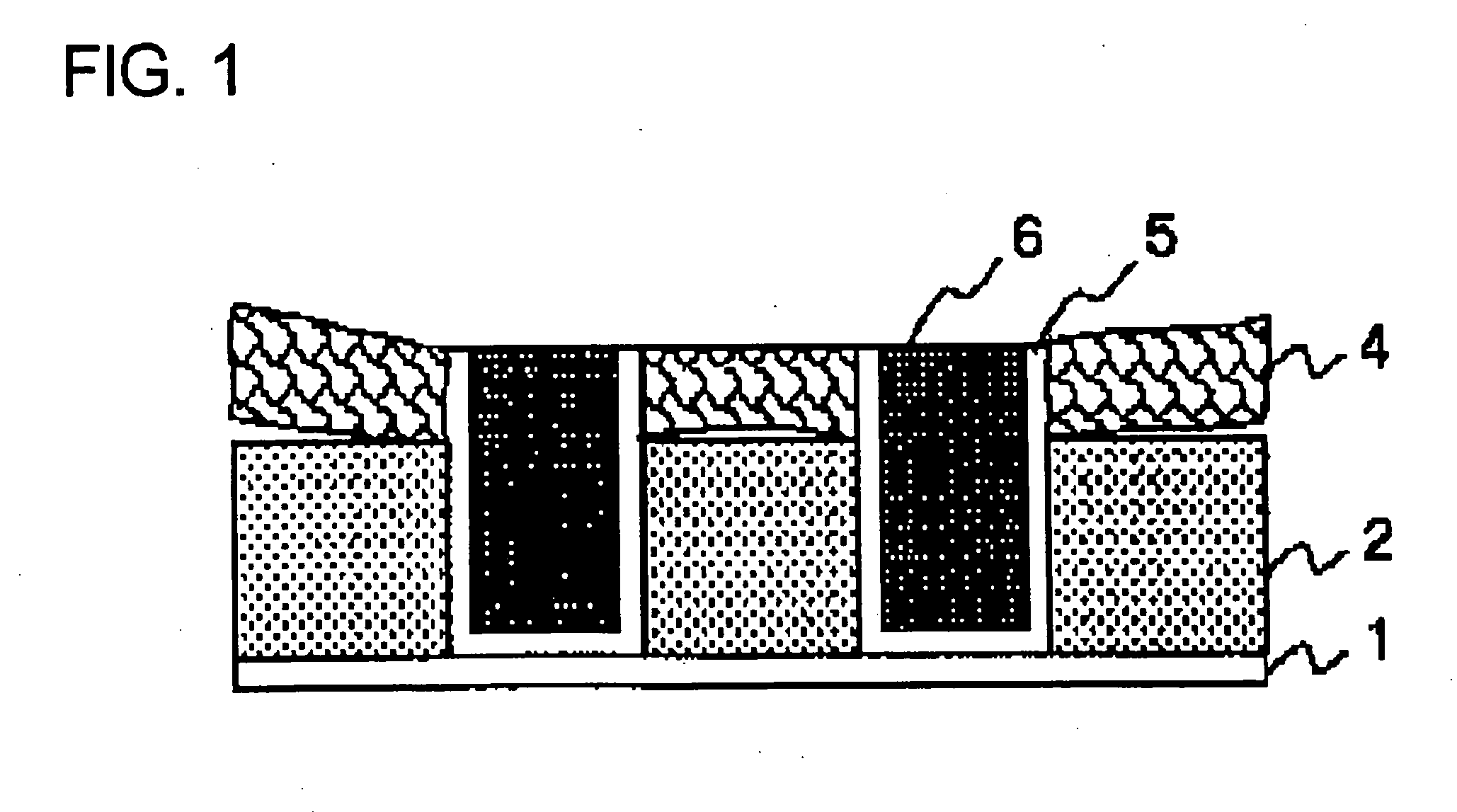

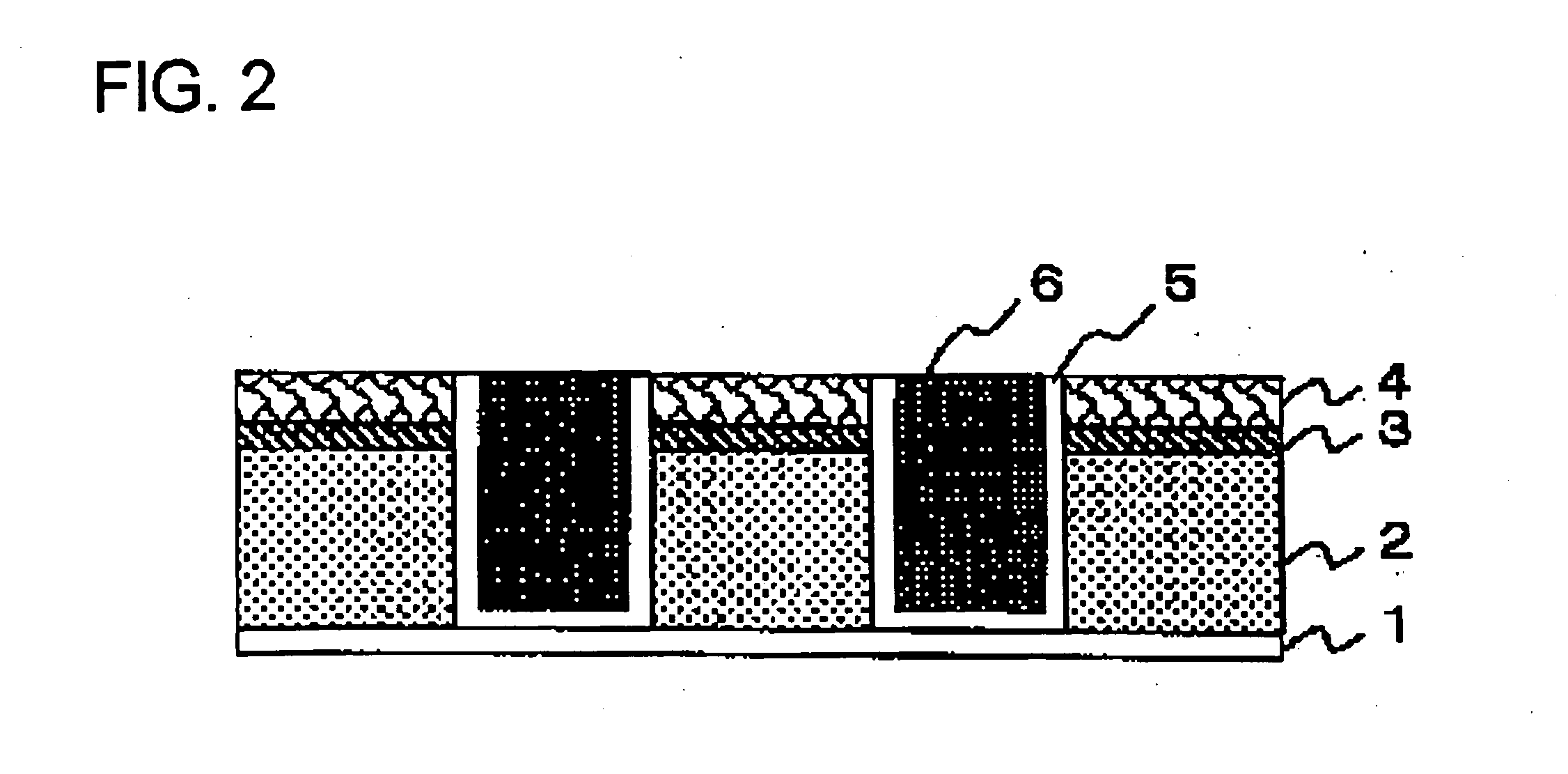

[0087] In the present example, the moisture-absorption of an interconnect structure comprising a L-Ox™ film and a SiOC film, which form an interlayer insulating film, were examined by the pressure cooker test (PCT). The structure of the sample to be examined is shown in FIG. 15. The sample comprises a Cu single damascene structure including a low-k film, in which a lower copper interconnect is coupled to an upper copper interconnect through a via plug of Cu. A silicon substrate was employed for the substrate, and SiC-type films were employed for an etch stop film and a barrier insulating film. Further, a dual-layer structure of SiON / SiO2 (having an upper layer of SiON and a lower layer of SiO2) was employed for a cover film. Since the cover film was provided thereto, introduction of water from the top surface of the interconnect structure was inhibited.

[0088] The low-k films were employed for both the interconnect portion and the via portion of the interlayer insulating film. The e...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Temperature | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Dielectric constant | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com