Magnetic impedance device, sensor apparatus using the same and method for manufacturing the same

a technology of magnetic impedance and sensor, which is applied in the direction of linear/angular speed measurement, instruments, transportation and packaging, etc., can solve the problems of deterioration of soft magnetic properties, difficult manufacturing of magnetic impedance devices, and much decreased sensitivity of devices, etc., to achieve low manufacturing cost, high heat resistance, and low sensitivity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

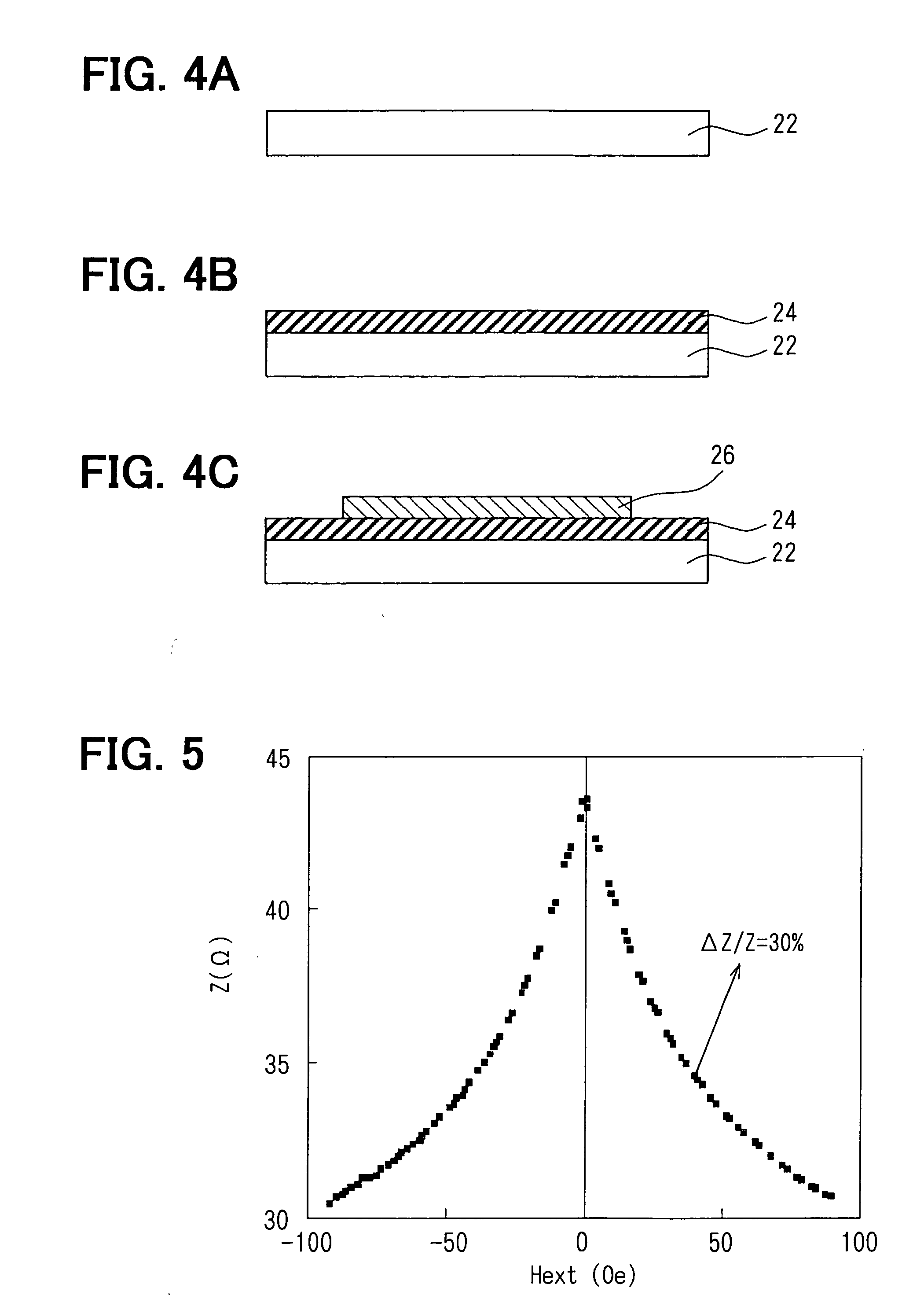

[0065] The inventors examine a magnetic thin film made of Ni—Fe series alloy as a magnetic material composing a magnetic layer in a magnetic impedance device, which has high heat resistance so that sensitivity of the device is not decreased even when the device is processed with heat treatment above 400° C.

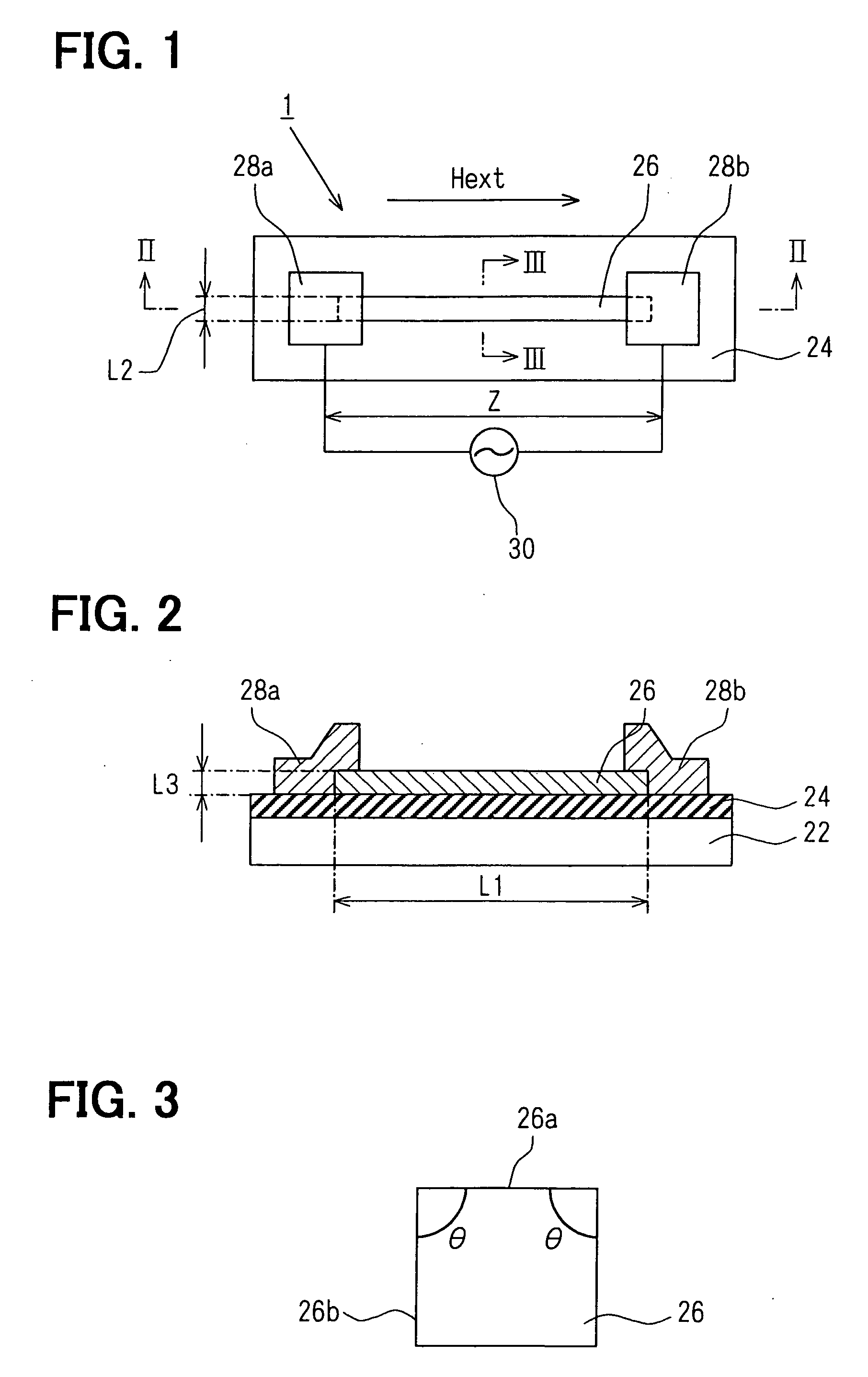

[0066] A magnetic impedance device according to a first embodiment utilizes magnetic impedance effect. The magnetic impedance effect is that impedance of the device changes in accordance with an external magnetic field when the device is energized with an alternating current. The device includes a magnetic layer made of Ni—Fe series alloy film. Here, Ni—Fe series alloy film has high Currie temperature and is made of polycrystalline. Accordingly, magnetic property of the magnetic layer made of Ni—Fe series alloy film does not change after the heat treatment above 400° C. For example, sensor sensitivity of the device is not decreased after the heat treatment. Therefore, the device ...

second embodiment

[0104] A magnetic impedance device 2 according to a second embodiment of the present invention includes the magnetic layer 26 and a protection layer 32, as shown in FIG. 19. The protection layer 32 covers the magnetic layer 26, and is made of electrically insulation material.

[0105] In general, a magnetic impedance device includes a magnetic layer having zero magneto-striction or low magneto-striction. This is because the magnetic layer having low magneto-striction is prevented from changing the magnetic properties generated by a striction of the magnetic layer, for example, from reducing the sensor sensitivity or the detection accuracy. However, the inventors obtain the following experimental results. In the device having a protection layer for covering the magnetic layer, an internal stress σ in the protection layer affects the magnetic properties of the magnetic layer, so that the sensor sensitivity is reduced. Further, there is a different influence of the internal stress σ affe...

third embodiment

[0131] A magnetic sensor apparatus 300 having a magnetic impedance device 301 according to a third embodiment of the present invention is shown in FIGS. 25-27. FIG. 27 shows a schematic diagram of the apparatus 300. The apparatus 300 includes the magnetic impedance device 301, a resistance 312, an oscillator 313, and an amplifier 314. Here, the resistance 312, the oscillator 313 and the amplifier 314 work as a periphery circuitry. The periphery circuitry may include a regulator circuit, and an interface circuit for communicating with a signal between the apparatus 300 and an external circuit. The device 301 is made of, for example, Ni—Fe series alloy, and connects to the resistance 312 in series. Here, the device 301 made of Ni—Fe series alloy has a wide dynamic range of detection of the magnetic field with using the magnetic impedance effect. Although the device 301 according to this embodiment is made of Ni—Fe alloy, the device 301 can be formed of other materials. The resistance ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width L3 | aaaaa | aaaaa |

| thickness L3 | aaaaa | aaaaa |

| thickness L3 | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com