Solid electrolytic capacitor and method for manufacturing the same

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

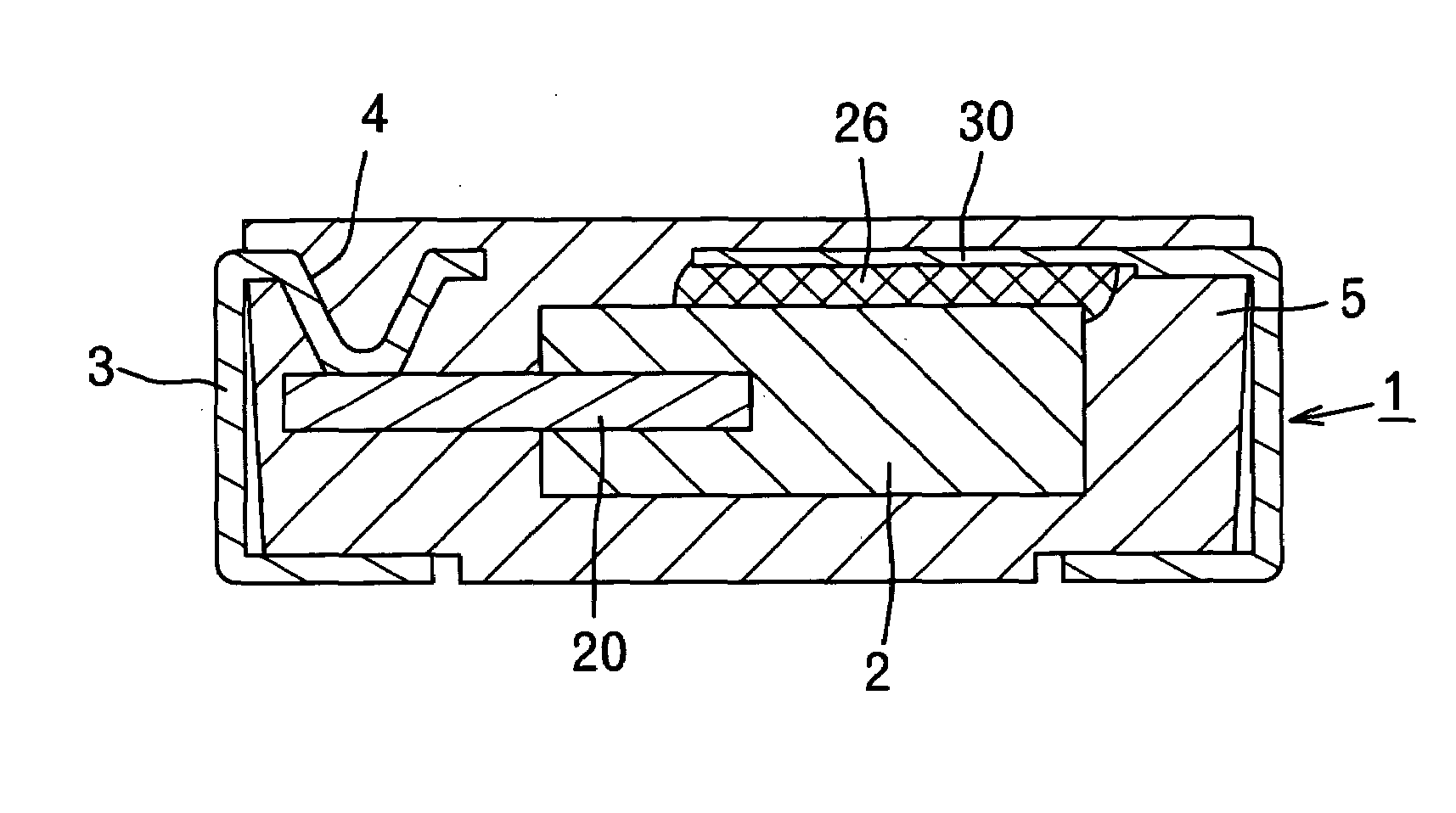

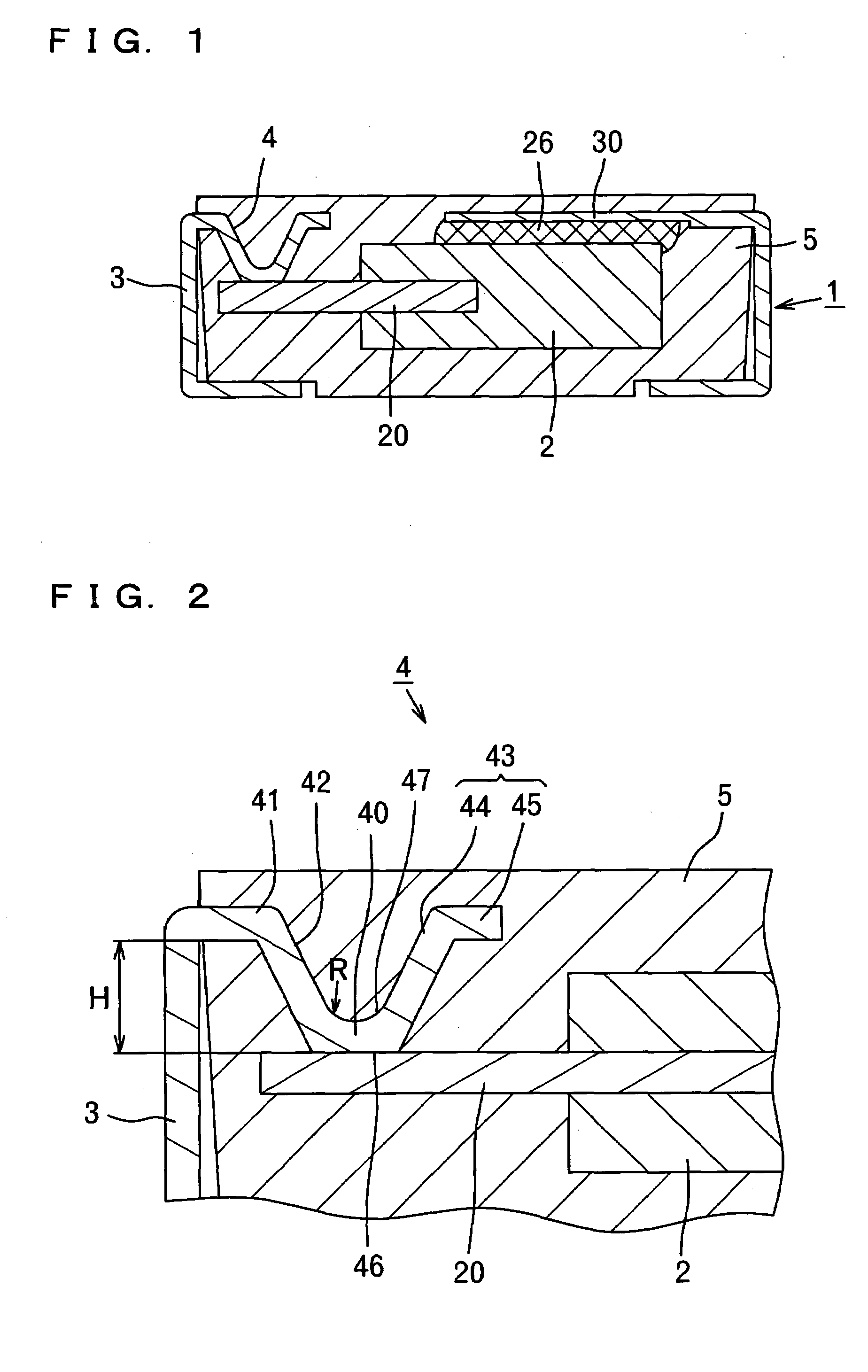

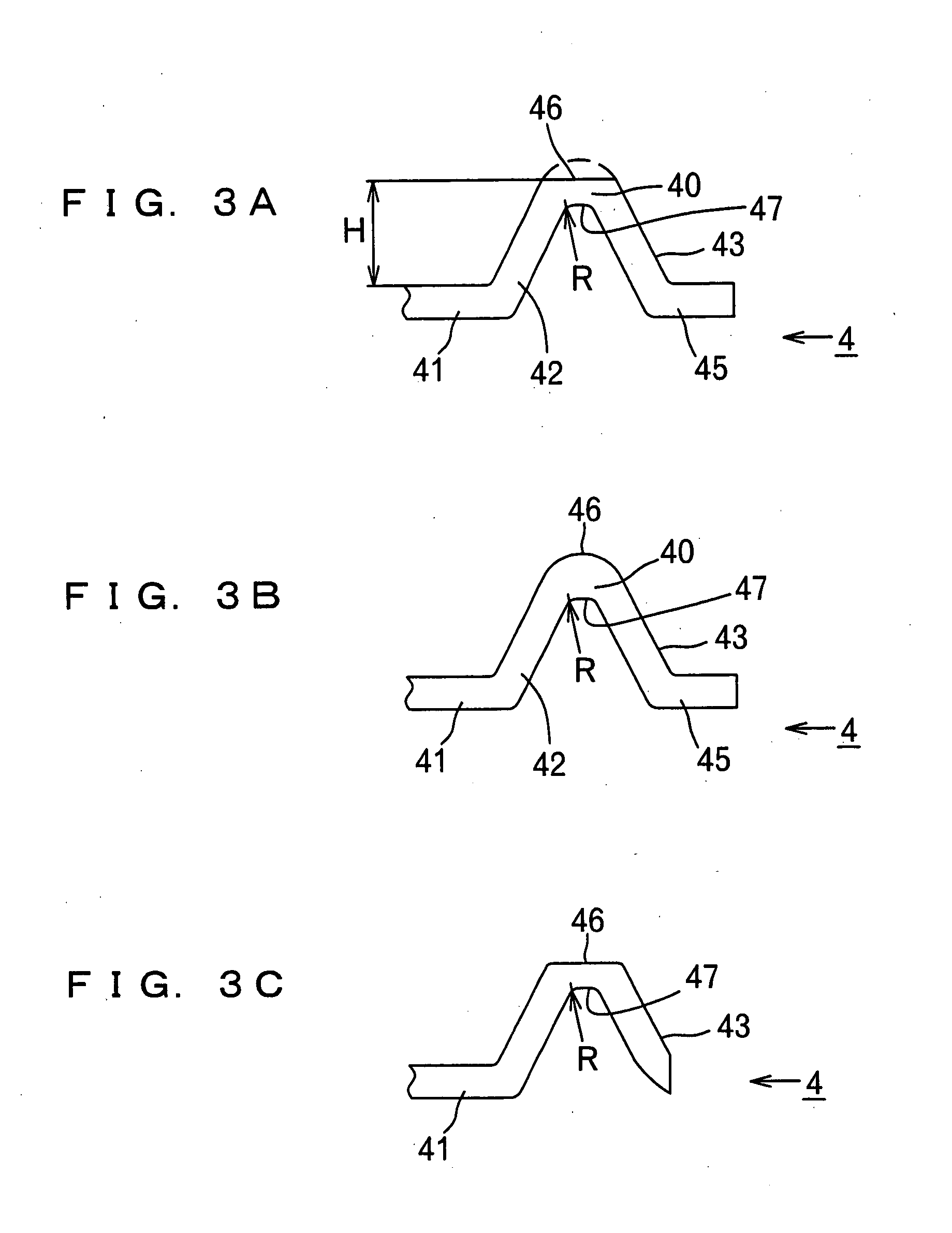

[0040]An embodiment of the present invention will be described below with reference to the accompanying drawings. A capacitor element (2) used in a solid electrolytic capacitor (1) of the present embodiment is the same as the prior art shown in FIG. 10. Here, polypyrrole is used to form the solid electrolytic layer (22) of the capacitor element (2), although other materials that may be used instead include conductive polymers such as polythiophene, polyaniline and polyfuran, and TCNQ (7, 7, 8, 8-tetracyanoquinodimethane) complex. An alloy that includes copper, an iron-nickel alloy or the like is used to form the lead frames (3) and (30).

[0041]Apart from tantalum, the valve metal constituting the anode body (24) and the anode lead (20) may, for example, be niobium, titanium, or aluminum.

[0042]FIG. 1 is a front sectional view of the solid electrolytic capacitor (1) of the present embodiment. A thin wire-like anode lead (20) protrudes from the capacitor element (2). An anode lead frame...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com