Semiconductor device with electrically broken fuse and its manufacture method

a technology of electrically broken fuse and semiconductor device, which is applied in the direction of static storage, digital storage, instruments, etc., can solve the problems of increasing consumption power and broadening the area occupied by breaker transistors, and achieve the effect of reducing the area occupied

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

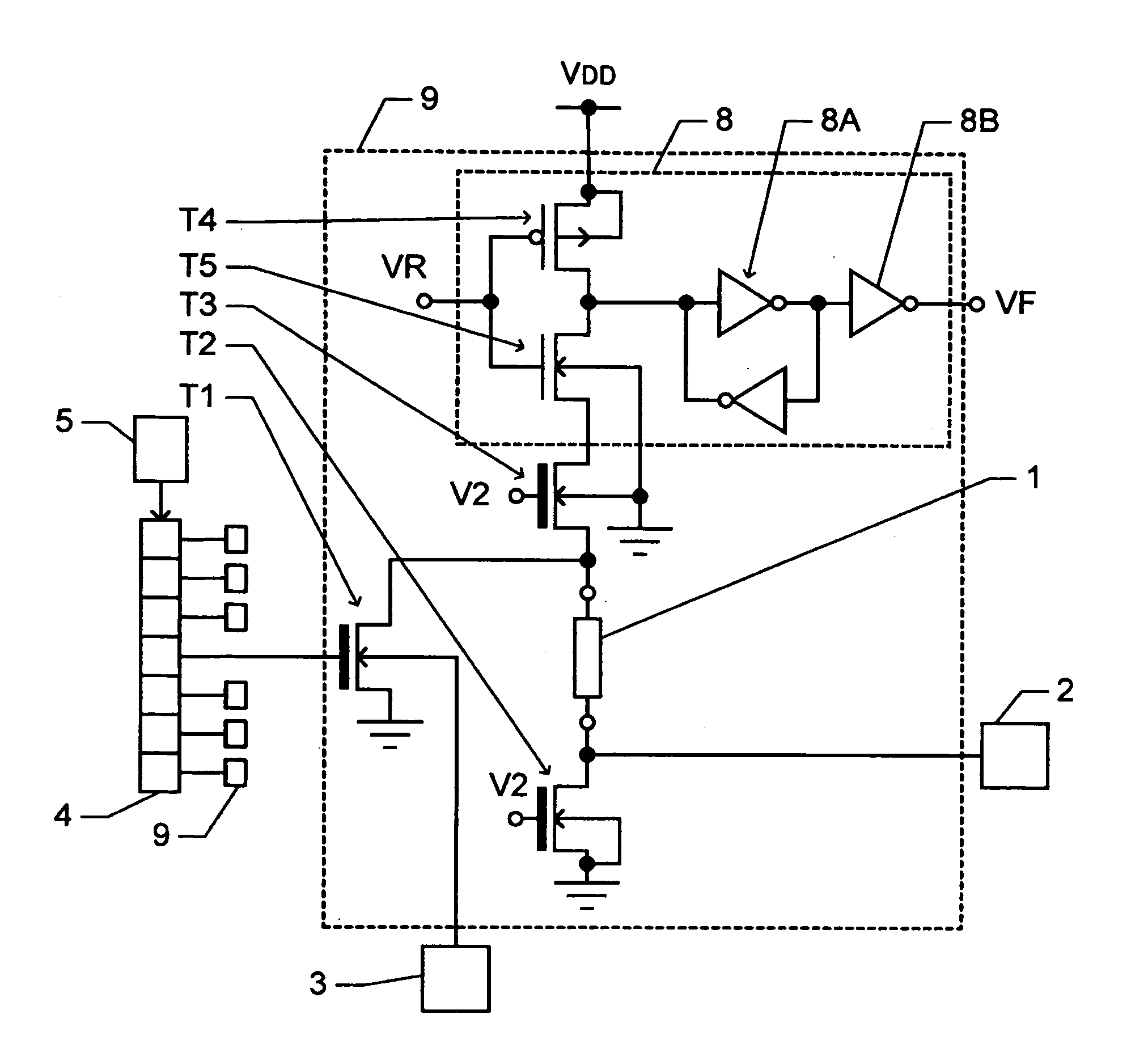

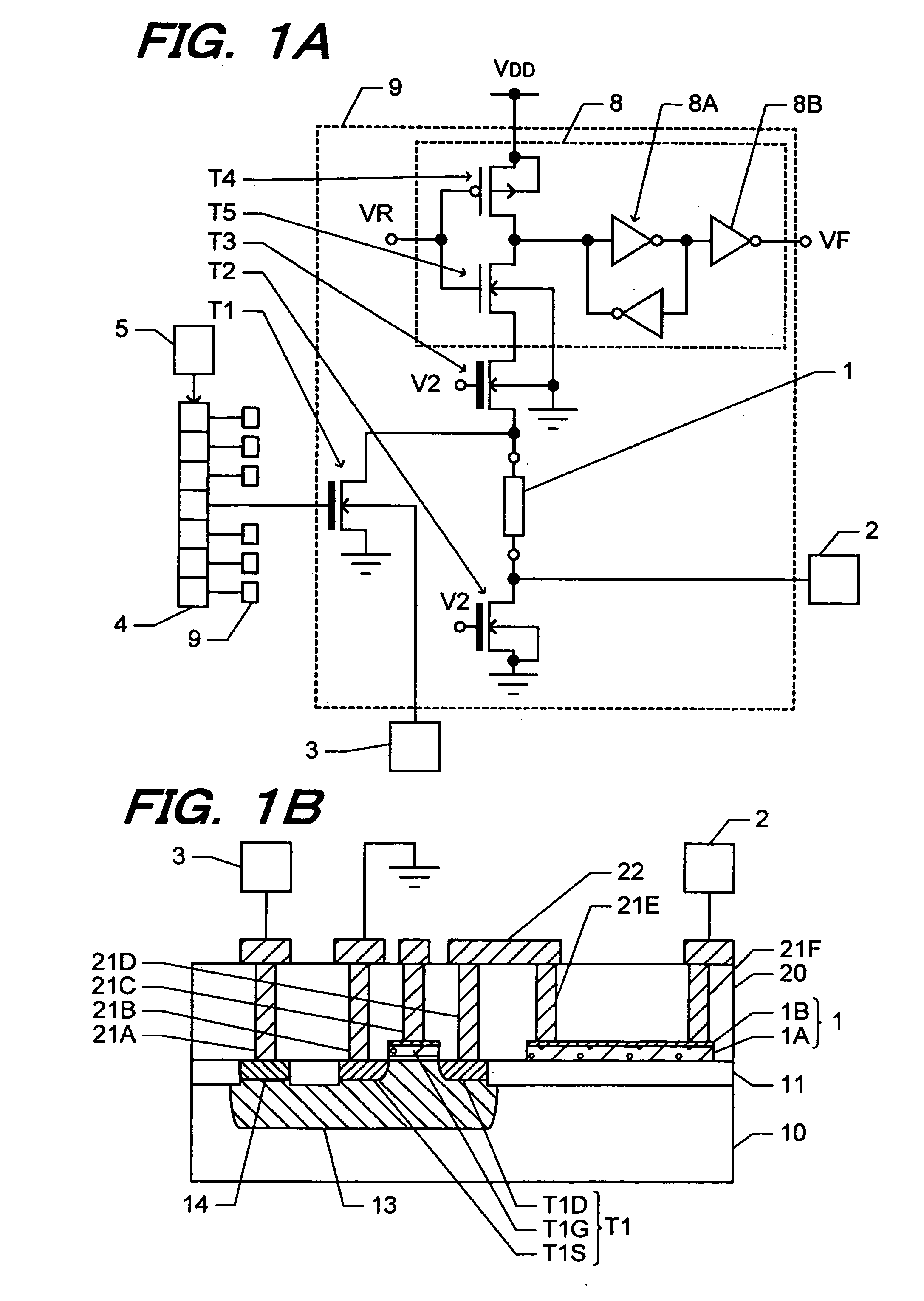

first embodiment

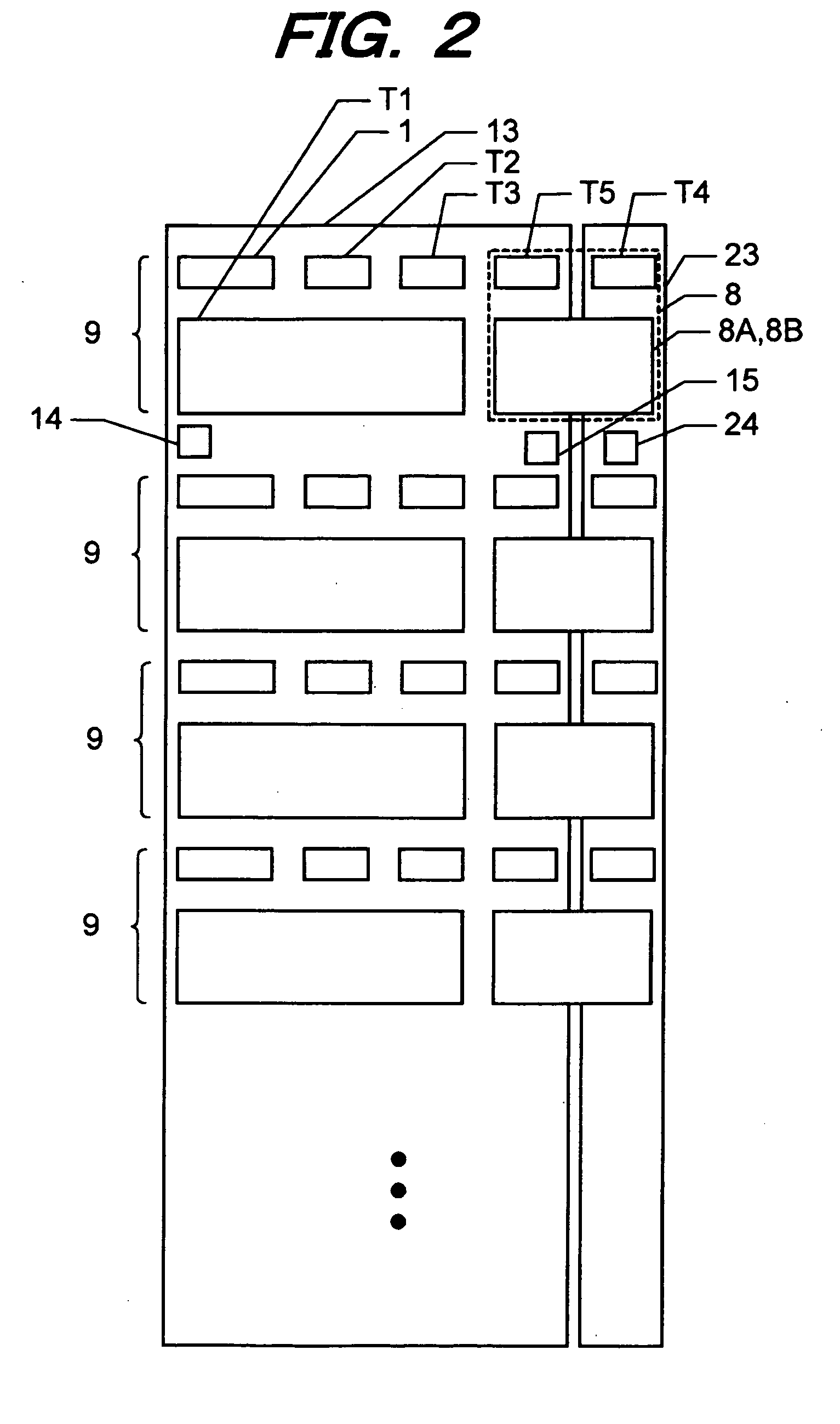

[0051]FIG. 2 shows an example of the layout of the semiconductor device of the The p-type well 13 extends vertically in FIG. 2. An n-type well 23 extends in parallel with the p-type well 13. A plurality of fuse blocks 9 are disposed along the longitudinal direction of the p-type well 13 and n-type well 23, and each fuse block 9 is placed across both of the p-type well 13 and n-type well 23. The layout of components in each fuse block 9 is congruent for all fuse blocks 9. In the following, the layout of components in one fuse block 9 will be described.

[0052]The breaker transistor T1, first and second read transistors T2 and T3 and the NMOS transistor T5 of the fuse state read circuit 8 are disposed in the p-type well 13. The electric fuse 1 is disposed on the isolation insulating film covering the upper surface of the p-type well 13. The PMOS transistor T4 of the fuse state read circuit 8 is disposed in the n-type well 23. MOS transistors constituting the latch circuit 8A and invert...

third embodiment

[0077]In the third embodiment, a ground potential is not applied to the breaker transistor well 13A from the VSS well contact 15. It is therefore preferable to apply a ground potential to the breaker transistor well 13A from the back-bias pad 3 during the operation of the semiconductor device.

[0078]FIG. 6 is an equivalent circuit diagram of a semiconductor device of the fourth embodiment. Description will be made by paying attention to different points from the equivalent circuit of the semiconductor device of the first embodiment shown in FIG. 1A. Description is omitted for components having the same structure as that of the semiconductor device of the first embodiment.

[0079]In the first embodiment, the breaker transistor T1 consists of an NMOS transistor, whereas in the fourth embodiment, a breaker transistor consists of a PMOS transistor. In response to this different structure, a breaker pad 2 is connected to an interconnection point between an electric fuse 1 and a second read ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com